Lexus ES: Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY LH (for 2WD)

(a) Preparation for check

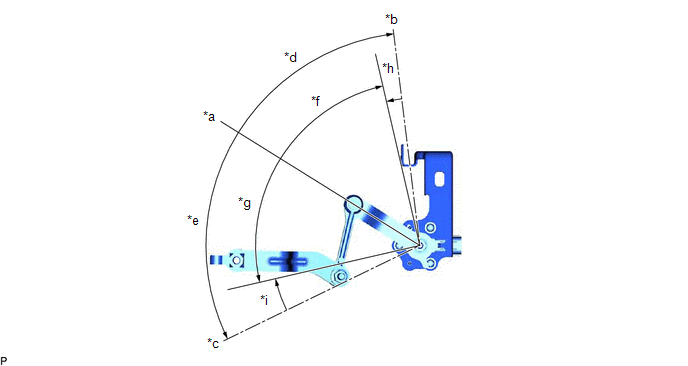

(1) Confirm the standard, high and low positions of the link that will be used in the following inspection.

- The standard position is 58° from the maximum link angle (high) and 51° from the maximum link angle (low).

- The high position (+45°) is 13° from the maximum link angle (high).

- The low position (-45°) is 6° from the maximum link angle (low).

| *a | Standard Position | *b | Maximum Link Angle (Low) |

| *c | Maximum Link Angle (High) | *d | 51° |

| *e | 58° | *f | -45° |

| *g | +45° | *h | 6° |

| *i | 13° | - | - |

(2) Connect 3 dry cell batteries (1.5 V) in series.

NOTICE:

Do not use rechargeable batteries as they may not output a voltage of 1.5 V.

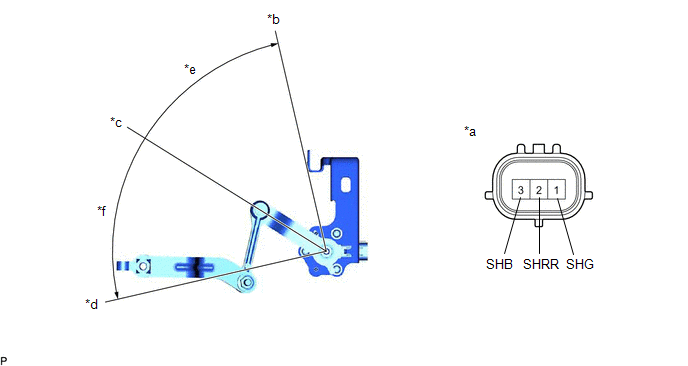

(3) Connect a positive (+) lead from the batteries to terminal 3 (SHB) and a negative (-) lead to terminal 1 (SHG).

| *a | Component without harness connected (Rear Height Control Sensor Sub-assembly LH) | *b | Low |

| *c | Standard Position | *d | High |

| *e | -45° | *f | +45° |

(4) Measure the voltage between terminals 2 (SHRR) and 1 (SHG) while slowly moving the link up and down.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2 (SHRR) - 1 (SHG) | +45° (High) | 4.5 V |

| 2 (SHRR) - 1 (SHG) | 0° (Standard position) | 2.5 V |

| 2 (SHRR) - 1 (SHG) | -45° (Low) | 0.5 V |

If the result is not as specified, replace the rear height control sensor sub-assembly LH.

2. INSPECT REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY LH (for AWD)

(a) Check the rear height control sensor sub-assembly LH.

(1) Connect 3 dry batteries of 1.5 V in series.

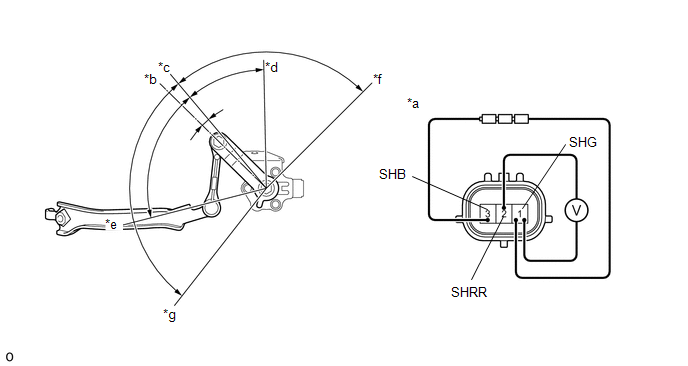

(2) Connect the positive (+) end of the batteries to terminal 3 (SHB) of the rear height control sensor sub-assembly LH and the negative (-) end of the batteries to terminal 1 (SHG). While slowly moving the sensor link up and down, measure the voltage between terminal 2 (SHRR) and terminal 1 (SHG).

NOTICE:

- Do not use rechargeable batteries as they may not output a voltage of 1.5 V.

- Do not apply a voltage of more than 6 V.

| *a | Component without harness connected (Rear Height Control Sensor Sub-assembly LH) | *b | Standard position (6.5° from horizontal position) |

| *c | Horizontal Position | *d | Height low (Full bound) (18.5° from standard position) |

| *e | Height high (Full rebound) (45.5° from standard position) | *f | Bound side link stop position (85° from standard position) |

| *g | Rebound side link stop position (102° from standard position) | - | - |

(3) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition | |

|---|---|---|---|

| If the result is not as specified, replace the rear height control sensor sub-assembly LH. | |||

| 1 (SHG) - 2 (SHRR) | Link moves upward from standard position to bound side (Height low) | From 18.5° to bound side link stop position | 0.5 V |

| 18.5° (Full Bound) | 1.69 V | ||

| Horizontal Position | - | 2.5 V | |

| Link moves downward from standard position to rebound side (Height high) | Standard position | 2.79 V | |

| 45.5° (Full Rebound) | 4.5 V | ||

| From 45.5° to rebound side link stop position | 4.5 V | ||