Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during level warning switch assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced (for HV Model)

| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

| Front bumper assembly | -

Measure ultrasonic sensor detection angle

-

Ultrasonic sensor detection angle registration

| -

Parking Support Alert System (for HV Model)

-

Parking Support Brake System (for HV Model)

| .gif) .gif) |

| Front television camera view adjustment | Panoramic View Monitor System (for HV Model) | for Initialization .gif) for Calibration .gif) |

Necessary Procedure After Parts Removed/Installed/Replaced (for Gasoline Model)

| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

| Front bumper assembly | -

Measure ultrasonic sensor detection angle

-

Ultrasonic sensor detection angle registration

| -

Parking Support Alert System (for Gasoline Model)

-

Parking Support Brake System (for Gasoline Model)

| .gif) .gif) |

| Front television camera view adjustment | Panoramic View Monitor System (for Gasoline Model) | for Initialization .gif) for Calibration .gif) |

PROCEDURE

1. REMOVE FRONT BUMPER ASSEMBLY

Click here .gif)

.gif)

2. DRAIN WASHER FLUID

Click here .gif)

3. REMOVE LEVEL WARNING SWITCH ASSEMBLY

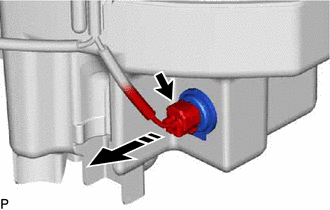

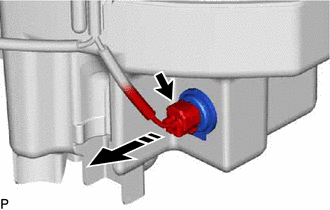

(a) Disconnect the connector.

.png) | Remove in this Direction |

(b) Remove the level warning switch assembly as shown in the illustration.

READ NEXT:

INSPECTION PROCEDURE 1. INSPECT LEVEL WARNING SWITCH ASSEMBLY HINT: This check should be performed with the level warning switch assembly installed to the washer jar. (a) Fill the washer jar with w

INSTALLATION PROCEDURE 1. INSTALL LEVEL WARNING SWITCH ASSEMBLY (a) Install the level warning switch assembly as shown in the illustration. *a Protrusion *b Marking Install in this

SEE MORE:

INSTALLATION PROCEDURE 1. INSTALL TRANSMISSION WIRE (a) Coat the O-ring of the transmission wire with Toyota Genuine ATF WS. (b) Install the transmission wire to the automatic transaxle case sub-assembly with the bolt. Torque: 5.4 N·m {55 kgf·cm, 48 in·lbf} (c) Connect the transmi

PROBLEM SYMPTOMS TABLE HINT: Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the suspected

© 2016-2026 Copyright www.lexguide.net

.gif)

.gif)

.gif)

.png)