Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during motor cable removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Auxiliary battery terminal is disconnected/reconnected | Perform steering sensor zero point calibration | Lane Control System (for HV Model) | |

| Pre-collision System (for HV Model) | |||

| Parking Support Brake System (for HV Model)* | |||

| Lighting System (for HV Model) | |||

| Memorize steering angle neutral point | Parking Assist Monitor System (for HV Model) | | |

| Panoramic View Monitor System (for HV Model) | | ||

| Initialize power trunk lid system | Power Trunk Lid System (for HV Model) | | |

| Replacement of ECM | Perform Vehicle Identification Number (VIN) registration | MIL illuminates | |

| Replacement of inverter with converter assembly | Resolver learning |

| |

-

*: When performing learning using the Techstream.

Click here

.gif)

CAUTION:

-

Orange wire harnesses and connectors indicate high-voltage circuits. To prevent electric shock, always follow the procedure described in the repair manual.

.png)

Click here

.gif)

-

To prevent electric shock, wear insulated gloves when working on wire harnesses and components of the high voltage system.

.png)

NOTICE:

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System)

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

PROCEDURE

1. REMOVE INVERTER WITH CONVERTER ASSEMBLY

Click here .gif)

2. REMOVE MOTOR CABLE

CAUTION:

Be sure to wear insulated gloves.

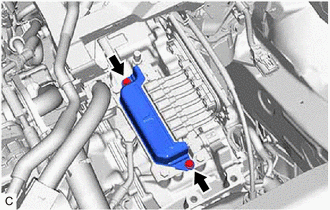

| (a) Remove the 2 bolts and connector cover from the hybrid vehicle transaxle assembly. |

|

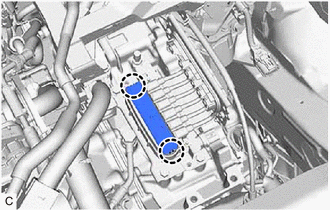

| (b) Disengage the 2 claws to remove the terminal cap from the hybrid vehicle transaxle assembly. |

|

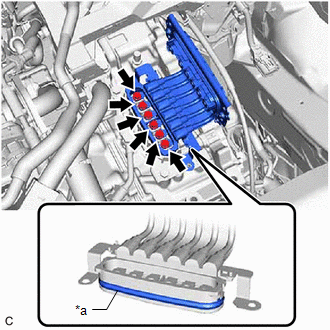

| (c) Using an insulated tool, remove the 6 bolts and motor cable from the hybrid vehicle transaxle assembly. NOTICE:

|

|