Lexus ES: Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR DIFFERENTIAL SUPPORT

(a) Install the rear differential support to the rear differential carrier assembly with 4 new bolts.

Torque:

72 N·m {734 kgf·cm, 53 ft·lbf}

2. INSTALL REAR NO. 1 DIFFERENTIAL SUPPORT

(a) Install the rear No. 1 differential support to the rear differential carrier assembly with 2 new bolts.

Torque:

55 N·m {561 kgf·cm, 41 ft·lbf}

(b) Install the rear upper differential mount stopper to the rear No. 1 differential support.

3. INSTALL REAR NO. 2 DIFFERENTIAL SUPPORT

(a) Install the rear No. 2 differential support to the rear differential carrier assembly with 2 new bolts.

Torque:

55 N·m {561 kgf·cm, 41 ft·lbf}

(b) Install the rear upper differential mount stopper to the rear No. 2 differential support.

4. INSTALL REAR DIFFERENTIAL CARRIER ASSEMBLY

NOTICE:

- Do not damage the contact surface when installing the rear differential carrier assembly.

- The remaining oil may leak out when installing the rear differential carrier assembly.

- Securely support the rear differential carrier assembly while performing this step to avoid excessively tilting or dropping the rear differential carrier assembly.

- Install the bolts and nuts with the rear differential carrier assembly secured.

(a) Support the rear differential carrier assembly with a transmission jack or equivalent.

(b) Temporarily install the rear differential carrier assembly to the rear suspension member sub-assembly with the 2 rear lower differential mount stoppers and 3 new bolts.

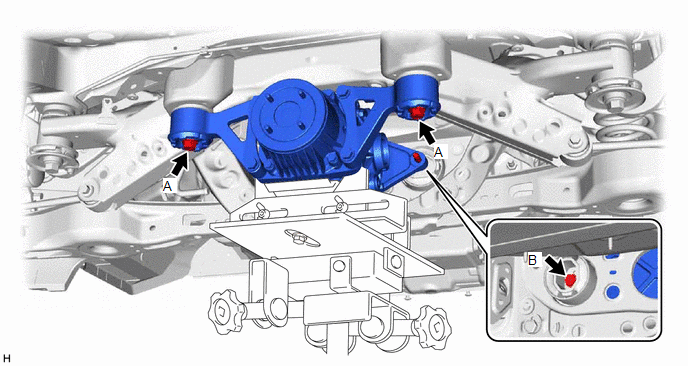

(c) Tighten the 2 bolts (A).

Torque:

86 N·m {877 kgf·cm, 63 ft·lbf}

NOTICE:

Do not tighten the bolts with the inner cylinder or rear differential mount cushion tilted.

(d) Tighten the bolt (B).

Torque:

130 N·m {1326 kgf·cm, 96 ft·lbf}

NOTICE:

Do not tighten the bolts with the inner cylinder or rear differential mount cushion tilted.

(e) Install the breather tube.

(f) Install the wire harness clamp bracket with the bolt.

Torque:

19.6 N·m {200 kgf·cm, 14 ft·lbf}

(g) Connect the 2 connectors.

(h) Engage the 2 wire harness clamps.

5. INSTALL REAR DRIVE SHAFT ASSEMBLY LH

Click here .gif)

6. INSTALL REAR DRIVE SHAFT ASSEMBLY RH

HINT:

Use the same procedure described for the LH side.

7. INSTALL REAR STABILIZER BAR

Click here .gif)

8. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

Click here .gif)

9. ADD DIFFERENTIAL OIL

Click here .gif)

10. INSPECT FOR DIFFERENTIAL OIL LEAK