Lexus ES: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

PROCEDURE

1. INSTALL VACUUM PUMP ASSEMBLY

(a) When reusing the vacuum pump assembly:

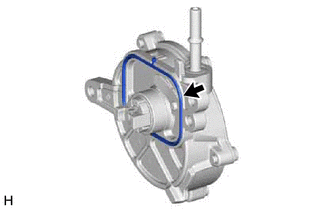

| (1) Install a new No. 1 vacuum pump O-ring to the vacuum pump assembly. |

|

| (b) Install the vacuum pump assembly so that the coupling teeth of the vacuum pump assembly and groove of the camshaft are engaged. NOTICE:

|

|

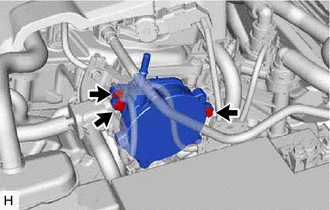

| (c) Using an 8 mm socket wrench, install the vacuum pump assembly with the 3 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE: After installation, check that there are no gaps between the matching surfaces and that the vacuum pump assembly is not installed at an angle. |

|

2. INSTALL ENGINE WIRE

(a) Engage the 2 clamps to install the engine wire.

3. CONNECT NO. 1 VACUUM HOSE CONNECTOR

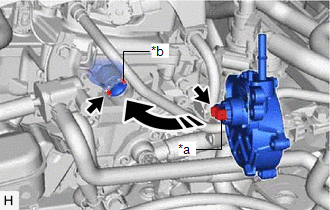

(a) Align the No. 1 vacuum hose connector with the vacuum pump assembly, and push them together until the No. 1 vacuum hose connector makes a "click" sound.

NOTICE:

- Check that there is no foreign matter on the connecting parts.

- After connecting the No. 1 vacuum hose connector, check that the vacuum pump assembly and No. 1 vacuum hose connector are securely connected by pulling on them.

4. INSPECT VACUUM PUMP OPERATION

Click here .gif)