Lexus ES: Inspection

INSPECTION

PROCEDURE

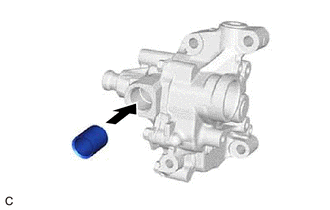

1. INSPECT OIL PUMP RELIEF VALVE

| (a) Coat the oil pump relief valve with engine oil, then check that it falls smoothly into the valve hole by its own weight. HINT: If the oil pump relief valve does not fall smoothly, replace the oil pump assembly. |

|

2. INSPECT OIL PUMP ROTOR

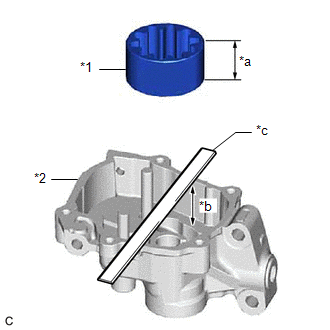

(a) Check the side clearance (Oil pump driven rotor side).

| (1) Using a vernier caliper, measure the width of the oil pump driven rotor. HINT: Perform the measurement at 3 random places. |

|

(2) Using a vernier caliper and precision straightedge, measure the depth of the oil pump body.

NOTICE:

Make sure to deduct the thickness of the precision straightedge.

HINT:

Perform the measurement at 3 random places.

(3) Subtract the oil pump driven rotor width measurement from the oil pump body depth measurement.

Standard Side Clearance:

0.025 to 0.070 mm (0.000984 to 0.00276 in.)

HINT:

If the result is not as specified, replace the oil pump assembly.

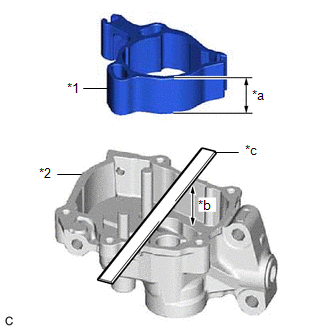

(b) Check the side clearance (Oil pump regulator ring side).

| (1) Using a vernier caliper, measure the width of the oil pump regulator ring. HINT: Perform the measurement at 3 random places. |

|

(2) Using a vernier caliper and precision straightedge, measure the depth of the oil pump body.

NOTICE:

Make sure to deduct the thickness of the precision straightedge.

HINT:

Perform the measurement at 3 random places.

(3) Subtract the oil pump regulator ring width measurement from the oil pump body depth measurement.

Standard Side Clearance:

0.025 to 0.075 mm (0.000984 to 0.00295 in.)

HINT:

If the result is not as specified, replace the oil pump assembly.