Lexus ES: Adjustment (one Time Recognition)

ADJUSTMENT (ONE TIME RECOGNITION)

CAUTION / NOTICE / HINT

NOTICE:

Make sure to read Before Starting Adjustment before proceeding with work.

Click here .gif)

PROCEDURE

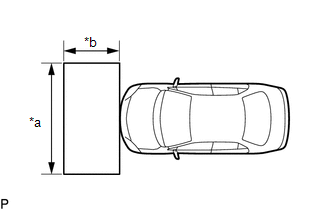

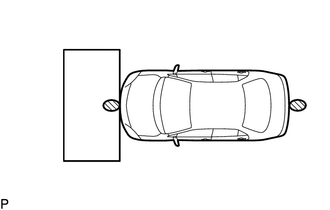

1. SECURE APPROPRIATE AREA FOR PERFORMING LEARNING

| (a) Park the vehicle on a level surface. HINT:

|

|

(b) Check the levelness of the ground.

(1) Check the levelness of the ground at the 2 points shown in the illustration.

.png) | Levelness Check Point |

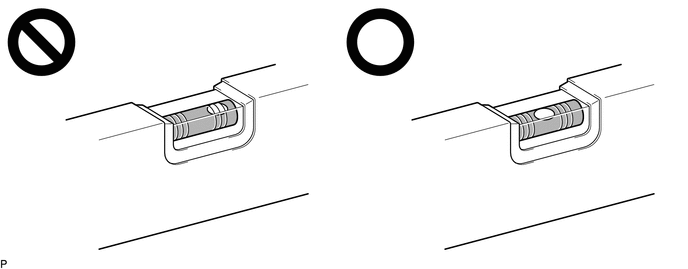

(2) Place the level on each levelness check point and check that the air bubble of the level is centered.

(c) Adjust the tire inflation pressure to the specified pressure.

Click here .gif)

.gif)

(d) Clean the windshield glass.

2. CREATE TARGET

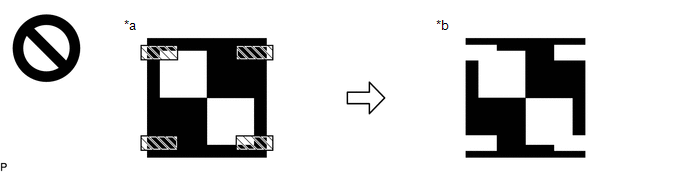

NOTICE:

Do not laminate the target or attach reflective materials, such as clear adhesive tape, to its surface. If there are reflective areas on the surface of the target, they will appear white to the forward recognition camera and the target may not be recognized.

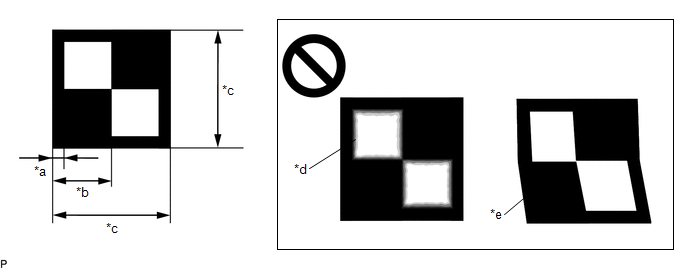

| *a | Actual Target | *b | Target as Seen by forward recognition camera |

.png) | Reflective Object or Surface | - | - |

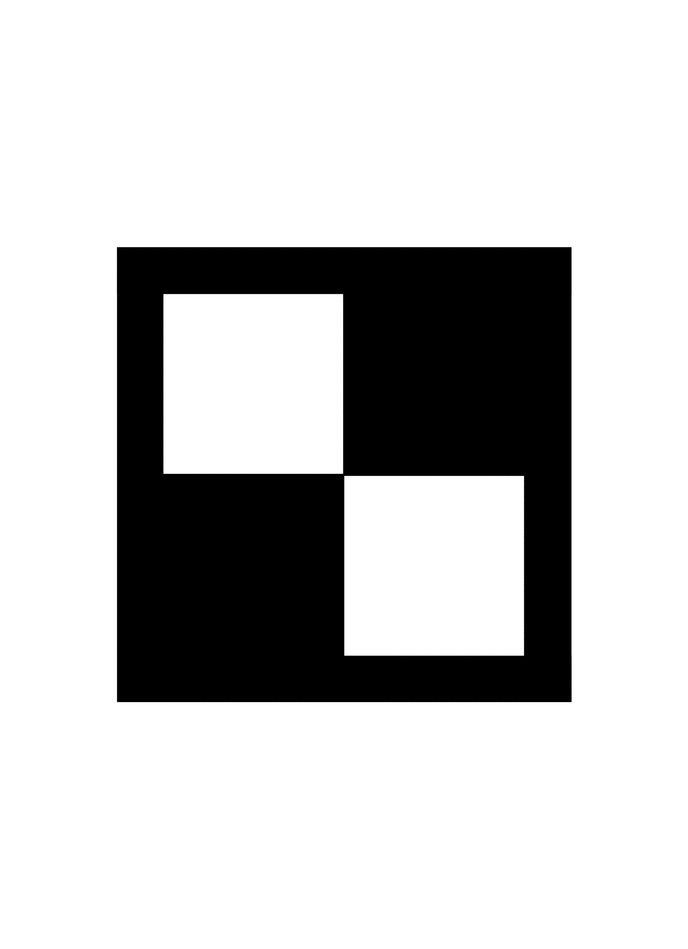

(a) Print 3 copies of the illustration.

(b) Check that the dimensions are within the values shown in the illustration.

| *a | 12 mm (0.472 in.) | *b | 60 mm (2.36 in.) |

| *c | 120 mm (4.72 in.) | *d | Blurry |

| *e | Distorted | - | - |

NOTICE:

- Make sure that the black areas of the target sheet are not glossy.

- Make sure that the borders of the black and white areas on the target sheet are straight, and are not warped or blurry.

HINT:

If the dimensions of the created target sheet are not within +/- 5 mm (0.197 in.) of the specified values, adjust the printer settings and reprint the target sheet so that the dimensions are as specified.

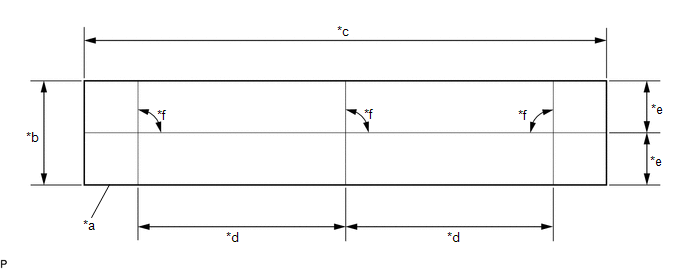

(c) Prepare a piece of cardboard and draw lines on it as shown in the illustration.

| *a | Cardboard | *b | 130 mm (5.12 in.) or more |

| *c | 730 mm (2.39 ft.) or more | *d | 297 mm (11.69 in.) |

| *e | 65 mm (2.56 in.) or more | *f | 90° |

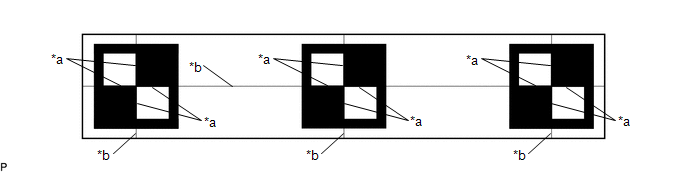

(d) Place the 3 target sheets on the cardboard with the black area of each at the top right and align the borders of the black and white areas with the lines as shown in the illustration.

| *a | Border of Black and White Area | *b | Line |

(e) Securely attach the target sheets to the cardboard using double-sided tape.

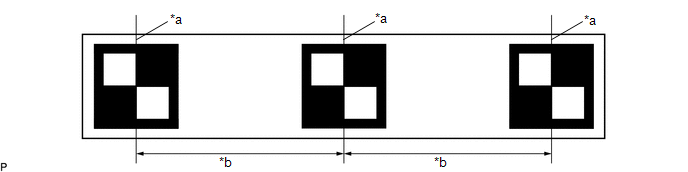

| *a | Border of Black and White Area | *b | 297 mm (11.69 in.) +/- 3 mm (0.12 in.) |

NOTICE:

Do not attach reflective materials, such as clear adhesive tape, to the target sheet surface as this may affect target recognition.

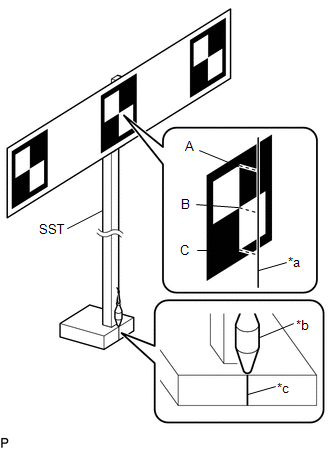

(f) Remove SST (reflector) from SST (base stand).

SST: 09870-60000

09870-60010

09870-60020

(g) Align the center of the target sheet with SST (reflector) and attach the target to SST (reflector) with double-sided tape.

(h) Install SST (reflector) to SST (base stand).

| (i) Hang a weight with a pointed tip from the top center of the target sheet and align it with the mark-off line of SST (base stand) as shown in the illustration. HINT:

|

|

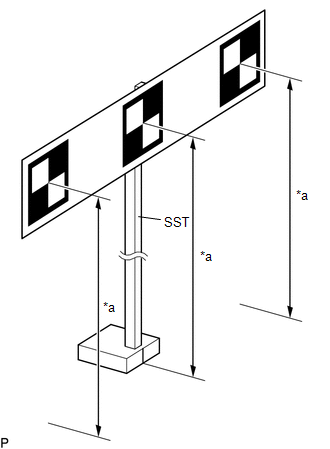

| (j) Move SST (reflector) up or down so that the center of the 3 target sheets is at the height shown in the illustration, and secure SST (reflector) in place. HINT: If the center of the target sheet is not within +/- 6 mm (0.24 in.) of the height specified, adjust the position of SST (reflector) so that the height is as specified. |

|

(k) Prepare an object to block the area behind the target. (If there are any objects which may be misrecognized as a target behind the area where a target will be placed.)

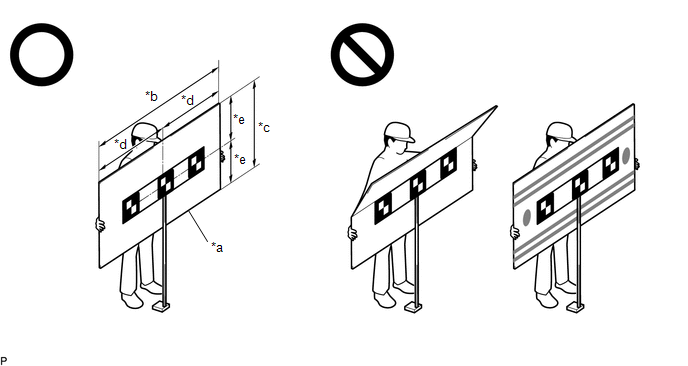

(1) When blocking the background by holding cardboard behind the target:

| *a | Cardboard | *b | 1160 mm (3.80 ft.) or more |

| *c | 560 mm (1.84 ft.) or more | *d | 580 mm (1.90 ft.) or more |

| *e | 280 mm (0.918 ft.) or more | - | - |

-

Prepare a piece of cardboard with the dimensions shown in the illustration.

HINT:

- Do not use cardboard that is bent or has a pattern or image on it.

- Do not use cardboard which has a reflective surface or reflective objects attached to it.

- Make sure to hold the cardboard in such a way that fingers are not within the target recognition area.

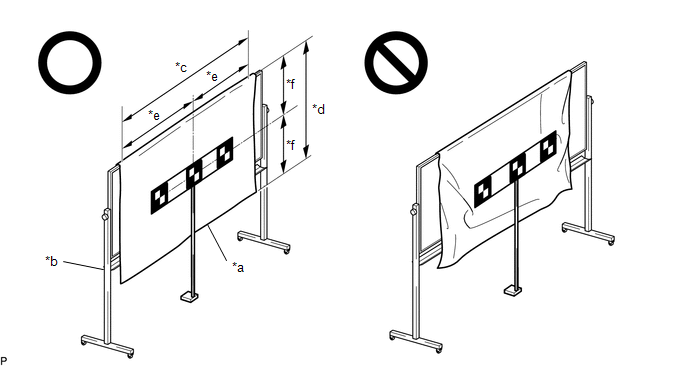

(2) When blocking the background using a light colored plain cloth:

| *a | Light Colored Plain Cloth | *b | Whiteboard or Equivalent |

| *c | 1160 mm (3.80 ft.) or more | *d | 560 mm (1.84 ft.) or more |

| *e | 580 mm (1.90 ft.) or more | *f | 280 mm (0.918 ft.) or more |

-

Cover a whiteboard or equivalent with light colored plain cloth and secure it.

HINT:

- Make sure to stretch the cloth to remove wrinkles before securing it.

- Make sure that the target recognition area is free of clear adhesive tape, reflective surfaces and reflective objects.

3. DETERMINE TARGET PLACEMENT POSITION

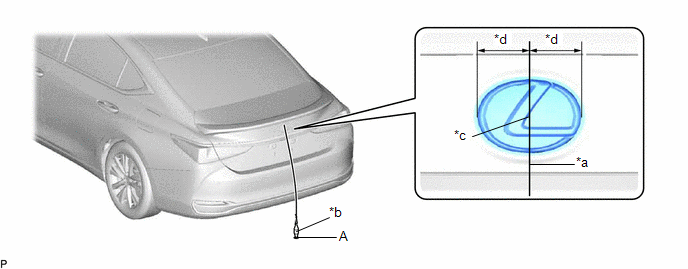

(a) Hang a weight with a pointed tip from the center of the rear emblem, and mark the rear center point of the vehicle (point A) on the ground.

| *a | String | *b | Weight |

| *c | Center | *d | Bilateral Symmetry |

HINT:

Lightly flick the string with your fingers several times to confirm that the string is perpendicular to the ground.

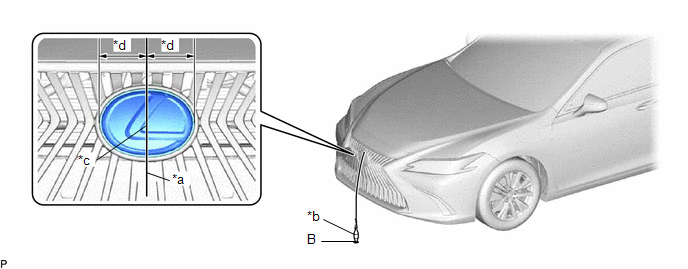

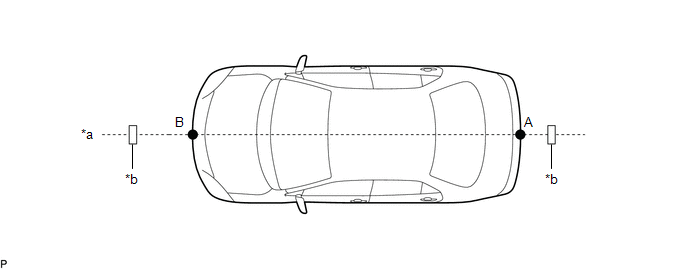

(b) Hang a weight with a pointed tip from the center of the front emblem, and mark the front center point of the vehicle (point B) on the ground (placement position).

| *a | String | *b | Weight |

| *c | Center | *d | Bilateral Symmetry |

HINT:

Lightly flick the string with your fingers several times to confirm that the string is perpendicular to the ground.

(c) Using tape and a string, create a line that connects point B to point A and extends at least 200 mm (7.87 in.) beyond the front center point of the vehicle (target position line).

| *a | String | *b | Tape |

HINT:

- Make sure the string is taut when securing it with tape.

- Lightly flick the string with your fingers several times to confirm that the string is aligned with point B.

4. PERFORM FORWARD RECOGNITION CAMERA OPTICAL AXIS LEARNING

NOTICE:

- Close all of the doors.

- Make sure that no one is inside the vehicle.

- Do not lean on the vehicle.

- Make sure that the headlights are turned off.

- Make sure the vehicle is unloaded.

(a) Perform Recognition Camera/Target Position Memory.

(1) Connect the Techstream to the DLC3.

(2) Turn the engine switch on (IG) (for Gasoline Model).

(3) Turn the power switch on (IG) (for HV Model).

(4) Turn the Techstream on.

(5) Enter the following menus: Chassis / Front Recognition Camera / Utility / Recognition Camera/Target Position Memory.

Chassis > Front Recognition Camera > Utility| Tester Display |

|---|

| Recognition Camera/Target Position Memory |

(6) Press "Next".*1

(7) Confirm the conditions displayed on the screen and then press "Next".

(8) According to the display on the Techstream, enter the following values for each respective item.

| Item | Value |

|---|---|

| Target Height | 1350 mm (53.15 in.) |

| Target Distance | 1924 mm (75.75 in.) |

| Distance between Targets | 297 mm (11.69 in.) |

| Target Size | 120 mm (4.72 in.) |

| Pitch Offset Angle | 0 deg. |

(9) If "Recognition Camera/Target Position Memory has failed." is displayed on the Techstream screen, confirm the conditions displayed on the screen, then press "Yes" and repeat the procedure from *1.

(10) Press "Exit" to exit the Recognition Camera/Target Position Memory utility.

(b) Perform Recognition Camera Axis Adjust (target positioning).

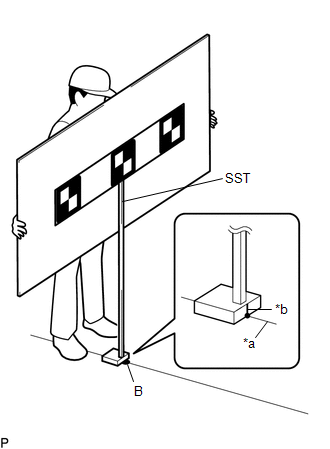

| (1) Position SST so that it is aligned with the target position line and the mark-off line is aligned with point B (placement position) as shown in the illustration. |

|

(2) Enter the following menus: Chassis / Front Recognition Camera / Utility / Recognition Camera Axis Adjust.

Chassis > Front Recognition Camera > Utility| Tester Display |

|---|

| Recognition Camera Axis Adjust |

(3) Press "Next".

(4) Check that the values stored in the ECU are correct and then press "Next".

(5) If "Failed to read axis adjustment data" is displayed, perform Recognition Camera/Target Position Memory, and repeat the procedure from *1.

(6) Confirm the conditions displayed on the screen and then press "Next".

(7) Select "One time recognition" and then press "Next".

(8) Check that the target is placed at point B (placement position) and then press "Next".

HINT:

If there are any objects which may be misrecognized as a target behind the area where a target will be placed, block the area behind the target with an appropriate object before pressing "Next".

(9) Perform the adjustment according to the display on the Techstream.

NOTICE:

If an error code is displayed, perform troubleshooting according to the following table, then perform the adjustment again.

| Error No. | Error Description | Cause of Error | Action to be Taken |

|---|---|---|---|

| 1 | Target 1 (Center) malfunction |

| Entering the adjustment area during beam axis adjustment is prohibited (Do not allow anything to pass between the target and the vehicle) |

| The values stored in recognition camera/target positions are correct | |||

| The target height and placement points are appropriate | |||

| There are no objects in the background that could be mistakenly detected as the target and the background is hidden | |||

| |||

| Check the camera installation condition (The camera is properly installed (completely installed) and has been installed after the cover is attached) | |||

| 2 | Target 2 (Left) malfunction |

| Entering the adjustment area during beam axis adjustment is prohibited (Do not allow anything to pass between the target and the vehicle) |

| The values stored in recognition camera/target positions are correct | |||

| The target height and placement points are appropriate | |||

| There are no objects in the background that could be mistakenly detected as the target and the background is hidden | |||

| |||

| Check the camera installation condition (The camera is properly installed (completely installed) and has been installed after the cover is attached) | |||

| 3 | Target 3 (Right) malfunction |

| Entering the adjustment area during beam axis adjustment is prohibited (Do not allow anything to pass between the target and the vehicle) |

| The values stored in recognition camera/target positions are correct | |||

| The target height and placement points are appropriate | |||

| There are no objects in the background that could be mistakenly detected as the target and the background is hidden | |||

| |||

| Check the camera installation condition (The camera is properly installed (completely installed) and has been installed after the cover is attached) | |||

| 1 and 4 displayed simultaneously | Target 1 (Center) stuck malfunction |

| SST (Target) does not move due to the wind, etc. |

| Adjust the vehicle so that it does not move

| |||

| There are no objects in the background that could be mistakenly detected as the target and the background is hidden | |||

| 2 and 4 displayed simultaneously | Target 2 (Left) stuck malfunction |

| SST (Target) does not move due to the wind, etc. |

| Adjust the vehicle so that it does not move

| |||

| There are no objects in the background that could be mistakenly detected as the target and the background is hidden | |||

| 3 and 4 displayed simultaneously | Target 3 (Right) stuck malfunction |

| SST (Target) does not move due to the wind, etc. |

| Adjust the vehicle so that it does not move

| |||

| There are no objects in the background that could be mistakenly detected as the target and the background is hidden | |||

| 5 | Target position and interval malfunction |

| The target height and placement points are appropriate |

| There are no objects in the background that could be mistakenly detected as the target and the background is hidden | |||

| 9 | FOE and role angle malfunction |

| The target height and placement points are appropriate (The levelness of the placement area is within the specified value. (See page 3. SECURE APPROPRIATE AREA FOR PERFORMING LEARNING)) |

| The values stored in recognition camera/target positions are correct | |||

| The camera is installed correctly (The camera is properly installed (completely installed) and has been installed after the cover is attached) | |||

| 10 | Target outside recognition area |

| The values stored in recognition camera/target positions are correct |

(10) Press "Exit" to exit the Recognition Camera Axis Adjust utility.

(11) Turn the engine switch off (for Gasoline Model).

(12) Turn the power switch off (for HV Model).

(13) Disconnect the Techstream from the DLC3.

(c) Forward recognition camera optical axis learning is complete.

(d) After beam axis adjustment completes, clear the following system vehicle control history entries.

(1) Clear vehicle control history (Dynamic radar cruise control system).

for Gasoline Model: Click here .gif)

for HV Model: Click here .gif)

(2) Clear vehicle control history (Front Camera System).

for Gasoline Model: Click here .gif)

for HV Model: Click here .gif)

(3) Clear vehicle control history (Lane Control System).

for Gasoline Model: Click here .gif)

for HV Model: Click here .gif)

(4) Clear vehicle control history (Road sign assist system).

for Gasoline Model: Click here .gif)

for HV Model: Click here .gif)

(5) Clear vehicle control history (Pre-collision system).

for Gasoline Model: Click here .gif)

.gif)

for HV Model: Click here .gif)

.gif)

(6) Clear vehicle control history (Lighting system).

for Gasoline Model: Click here .gif)

for HV Model: Click here .gif)