Lexus ES: Inspection

INSPECTION

PROCEDURE

1. INSPECT PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

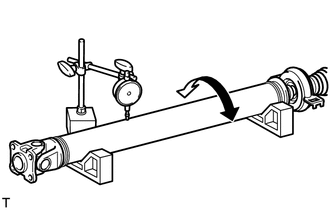

| (a) Using a dial indicator, measure the runout of the rear propeller shaft assembly (for front side). Maximum Runout: 0.6 mm (0.0236 in.) NOTICE: The dial indicator must be set at a right angle to the center of the rear propeller shaft assembly. If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. | |

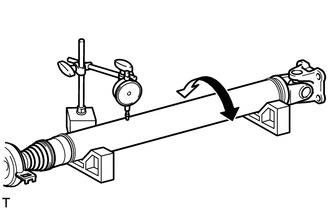

| (b) Using a dial indicator, measure the runout of the rear propeller shaft assembly (for rear side). Maximum Runout: 0.6 mm (0.0236 in.) NOTICE: The dial indicator must be set at a right angle to the center of the rear propeller shaft assembly. If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. | |

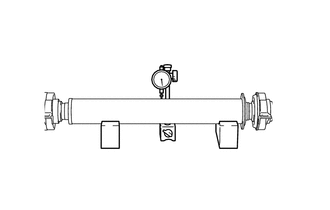

| (c) Using a dial indicator, measure the runout of the intermediate shaft assembly. Maximum Runout: 0.6 mm (0.0236 in.) NOTICE: The dial indicator must be set at a right angle to the center of the intermediate shaft assembly. If the shaft runout exceeds the maximum, replace the propeller with center bearing shaft assembly. | |

READ NEXT:

INSTALLATION PROCEDURE 1. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY (a) When reusing a propeller with center bearing shaft assembly and rear differential carrier assembly: (1

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during pro

Problem Symptoms TablePROBLEM SYMPTOMS TABLE HINT: Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms ar

SEE MORE:

COMPONENTS ILLUSTRATION *1 NO. 2 FLOOR UNDER COVER - - N*m (kgf*cm, ft.*lbf): Specified torque - - ILLUSTRATION *1 FUEL TANK ASSEMBLY *2 FUEL TANK MAIN TUBE SUB-ASSEMBLY *3 NO. 1 FUEL TANK PROTECTOR SUB-ASSEMBLY *4 FUEL TANK TO FILLER PIPE HOSE *5 NO

SYSTEM DESCRIPTION POWER WINDOW CONTROL SYSTEM DESCRIPTION (a) The power window control system controls the power window operation using the power window regulator motor assemblies. The main controls of this system are the multiplex network master switch assembly (mounted on the driver door), power

© 2016-2026 Copyright www.lexguide.net