Lexus ES: Electric Parking Brake System AUTO Function Circuit

DESCRIPTION

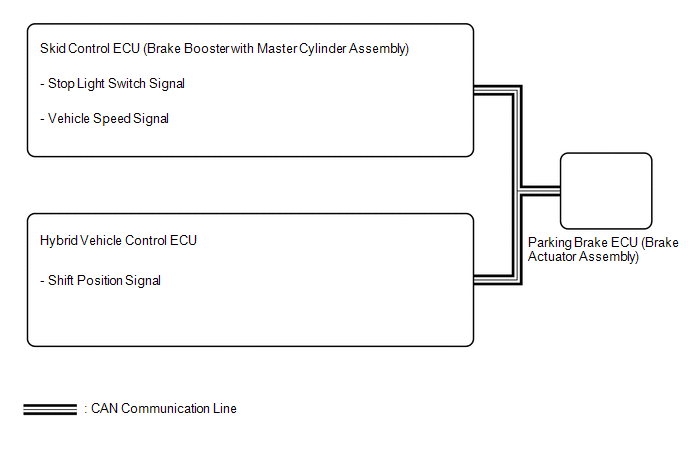

The parking brake ECU (brake actuator assembly) receives shift position information from the hybrid vehicle control ECU via CAN communication, and wheel speed signal and stop light switch signals from the skid control ECU (brake booster with master cylinder assembly).

The electric parking brake system AUTO function (shift-linked function) automatically releases the parking brake when the following conditions are met: 1) Power switch is on (IG), 2) brake pedal is depressed, and 3) shift lever is moved out of P. When the shift lever is moved to P with these conditions met, the function automatically locks the parking brake.

The electric parking brake system AUTO (shift-linked function) automatically engages the parking brake when the shift lever is moved to P and disengages the parking brake when the shift lever is moved out of P when the power switch is on (IG) and the brake pedal is depressed.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

The parking brake indicator light blinks (red) when the power switch is turned on (IG) after replacing the parking brake ECU (brake actuator assembly). Operate the electric parking brake switch assembly to turn off the parking brake indicator light (red).

PROCEDURE

| 1. | CHECK DTC (ELECTRONICALLY CONTROLLED BRAKE SYSTEM) |

(a) Check for DTCs.

Chassis > ABS/VSC/TRC > Trouble Codes| Result | Proceed to |

|---|---|

| DTC is not output | A |

| DTC is output | B |

| B | .gif) | GO TO ELECTRONICALLY CONTROLLED BRAKE SYSTEM |

|

| 2. | CHECK DTC (HYBRID CONTROL SYSTEM) |

(a) Check for DTCs.

Powertrain > Hybrid Control > Trouble Codes| Result | Proceed to |

|---|---|

| DTC is not output | A |

| DTC is output | B |

| A | .gif) | REPLACE PARKING BRAKE ECU (BRAKE ACTUATOR ASSEMBLY) |

| B | .gif) | GO TO HYBRID CONTROL SYSTEM |

.gif)

.gif)