Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during rear crankshaft oil seal removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Battery terminal is disconnected/reconnected | Perform steering sensor zero point calibration | Lane Control System | |

| Pre-collision System | |||

| Parking Support Brake System*1 | |||

| Lighting System | |||

| Memorize steering angle neutral point | Parking Assist Monitor System | | |

| Panoramic View Monitor System | | ||

| Initialize power trunk lid system | Power Trunk Lid System | | |

| Replacement of ECM | Vehicle Identification Number (VIN) registration | MIL comes on | |

| ECU communication ID registration (Immobiliser system) | Engine start function | | |

| Gas leak from exhaust system is repaired | Inspection after repair |

| |

| Replacement of automatic transaxle assembly |

|

| for Initialization: for Registration: |

| Replacement of ECM (If transaxle compensation code read from ECM) |

| ||

| Replacement of ECM (If transaxle compensation code not read from ECM) |

| ||

| Replacement of ECM | Code registration (Smart access system with push-button start (for Start Function, Gasoline Model) |

| |

| Replacement of automatic transaxle fluid | ATF thermal degradation estimate reset | The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly | |

| Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) | Rear television camera assembly optical axis adjustment (Back camera position setting) | Parking assist monitor system | for Initialization: for Calibration: |

| Perform headlight ECU sub-assembly LH initialization | Lighting system | | |

| Front wheel alignment adjustment |

|

| |

| Front television camera view adjustment | Panoramic View Monitor System | for Initialization for Calibration |

| Replacement of front bumper assembly |

|

| |

-

*1: When performing learning using the Techstream.

Click here

.gif)

- *2: Not necessary when ECM replaced with new one

NOTICE:

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System)

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

Click here .gif)

2. REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly level.

- To prevent the No. 2 oil pan sub-assembly from deforming, do not place any attachments under the No. 2 oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

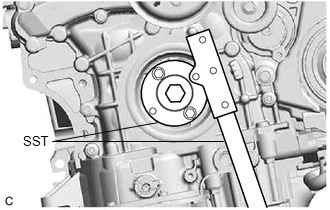

| (b) Using SST, hold the crankshaft pulley. SST: 09213-70011 09213-70020 SST: 09330-00021 |

|

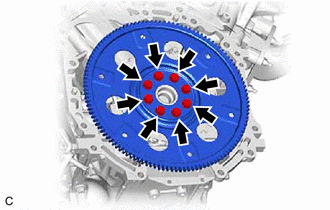

| (c) Remove the 8 bolts, the rear drive plate spacer, the drive plate and ring gear sub-assembly. |

|

3. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

(a) Remove the No. 1 crankshaft position sensor plate.

4. REMOVE REAR ENGINE OIL SEAL

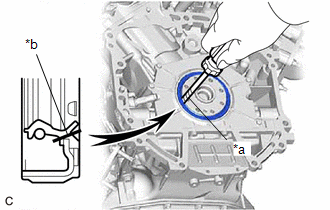

| (a) Using a knife, cut through the lip of the rear engine oil seal. |

|

(b) Using a screwdriver with its tip wrapped with protective tape, pry out the rear engine oil seal.

NOTICE:

Be careful not to damage the crankshaft.