Lexus ES: Disassembly

DISASSEMBLY

PROCEDURE

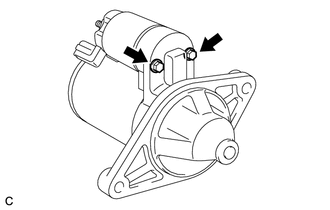

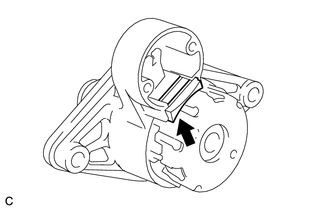

1. REMOVE MAGNET STARTER SWITCH ASSEMBLY

| (a) Remove the 2 bolts. |

|

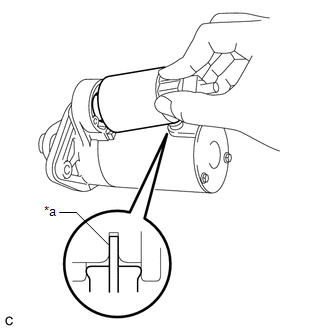

| (b) While lifting the rear of the magnet starter switch assembly disconnect it from terminal C. |

|

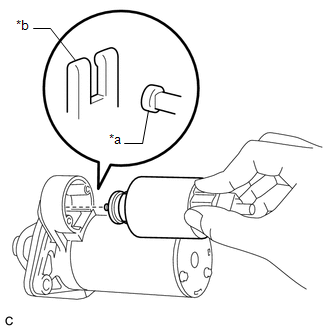

| (c) While lifting the rear of the magnet starter switch assembly, remove the hook from the pinion drive lever, then remove the magnet starter switch assembly. |

|

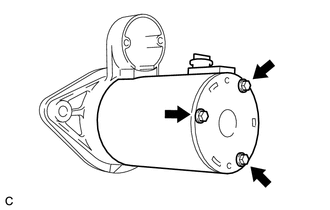

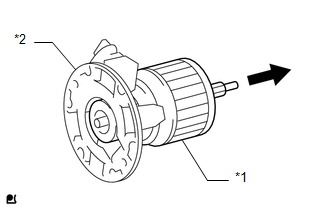

2. REMOVE STARTER YOKE ASSEMBLY

| (a) Remove the 3 through bolts and pull out the starter yoke assembly together with the starter commutator end frame assembly. |

|

3. REMOVE STARTER COMMUTATOR END FRAME ASSEMBLY

| (a) Remove the starter commutator end frame assembly from the starter yoke assembly. |

|

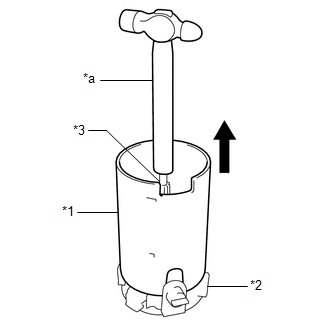

4. REMOVE STARTER BRUSH HOLDER ASSEMBLY

| (a) Remove the starter yoke assembly while holding down the starter armature assembly and starter brush holder assembly with the handle of a hammer. HINT: The starter armature assembly will be attracted by the magnetic field of the starter yoke assembly. Hold the starter armature assembly with the handle of the hammer. |

|

5. REMOVE STARTER ARMATURE ASSEMBLY

| (a) Remove the starter armature assembly from the starter brush holder assembly. |

|

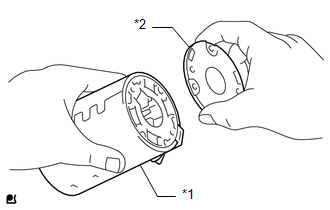

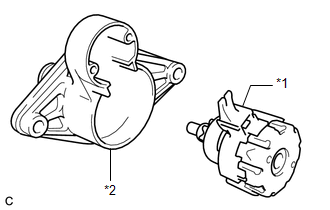

6. REMOVE STARTER CENTER BEARING CLUTCH SUB-ASSEMBLY

| (a) Remove the rubber seal from the starter drive housing assembly. |

|

| (b) Remove the starter center bearing clutch sub-assembly from the starter drive housing assembly. |

|