Lexus ES: Terminals Of Ecu

TERMINALS OF ECU

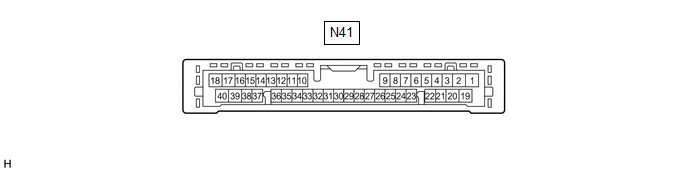

CLEARANCE WARNING ECU ASSEMBLY

(a) Disconnect the N41 clearance warning ECU assembly connector.

(b) Measure the voltage and resistance on the wire harness side connector according to the value(s) in the table below.

| Terminal No. (Symbol) | Wiring Color | Terminal Description | Condition | Specified Condition |

|---|---|---|---|---|

| N41-1 (IG) - N41-30 (E) | B - W-B | IG power source signal | Engine switch off | Below 1 V |

| Engine switch on (IG) | 11 to 14 V | |||

| N41-30 (E) - Body ground | W-B - Body ground | Ground | Always | Below 1 Ω |

(c) Reconnect the N41 clearance warning ECU assembly connector.

(d) Measure the voltage and check for pulses according to the value(s) in the table below.

| Terminal No. (Symbol) | Wiring Color | Terminal Description | Condition | Specified Condition |

|---|---|---|---|---|

| N41-4 (BOF) - N41-30 (E) | R - W-B | Power source for front sensor circuit | Engine switch off | Below 1 V |

| 11 to 14 V | |||

| N41-6 (E5) - N41-30 (E) | W - W-B | Ground for front clearance sonar | Always | Below 1 Ω |

| N41-8 (SOF) - N41-30 (E) | B - W-B | Front sensor communication signal (Front clearance sonar sensor) |

| Pulse generation (Refer to waveform 1) |

| N41-14 (CBZ) - N41-13 (EF) | LG - L | No. 1 clearance warning buzzer signal | Buzzer sounding | Pulse generation (Refer to waveform 2) |

| N41-15 (BBZ) - N41-16 (ER) | G - BE | No. 2 clearance warning buzzer signal | Buzzer sounding | Pulse generation (Refer to waveform 2) |

| N41-22 (BOR) - N41-30 (E) | LG - W-B | Power source for rear sensor circuit | Engine switch off | Below 1 V |

| 11 to 14 V | |||

| N41-23 (E1) - N41-30 (E) | GR - W-B | Ground for rear clearance sonar | Always | Below 1 Ω |

| N41-24 (SOR) - N41-30 (E) | SB - W-B | Rear sensor communication signal (Rear clearance sonar sensor) |

| Pulse generation (Refer to waveform 1) |

| N41-28 (STP) - N41-30 (E)* | V - W-B | Reverse signal input |

| 11 to 14 V |

| Below 1 V | |||

| N41-31 (IND) - N41-30 (E)* | P - W-B | Display select signal |

| Below 3 V |

| 8 V or higher |

- *: w/o Panoramic View Monitor System

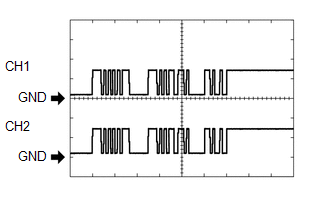

(e) Using an oscilloscope, check waveform 1.

(1) Waveform 1 (Reference)

| Item | Content |

|---|---|

| Measurement terminal |

|

| Measurement setting | 5 V/DIV., 1 ms./DIV. |

| Condition |

|

HINT:

The waveforms for CH1 and CH2 are same.

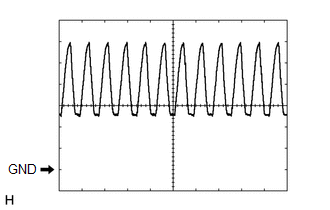

(f) Using an oscilloscope, check waveform 2.

(1) Waveform 2 (Reference)

| Item | Content |

|---|---|

| Measurement terminal | N41-14 (CBZ) - N41-13 (EF) N41-15 (BBZ) - N41-16 (ER) |

| Measurement setting | 2 V/DIV., 500 μs./DIV. |

| Condition | Buzzer sounding |

HINT:

The amplitude of the waveform changes according to the set volume.

BLIND SPOT MONITOR SENSOR RH (w/ Blind Spot Monitor System)

Click here .gif)

BLIND SPOT MONITOR SENSOR LH (w/ Blind Spot Monitor System)

Click here .gif)

REAR TELEVISION CAMERA ASSEMBLY (w/ Panoramic View Monitor System)

Click here .gif)