Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

Click here .gif)

.gif)

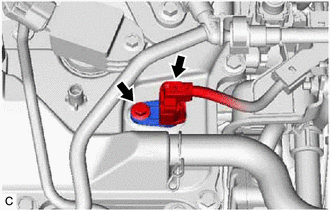

2. REMOVE CAMSHAFT POSITION SENSOR (for Intake Side)

| (a) Disconnect the camshaft position sensor connector. | |

(b) Using an 8 mm socket wrench, remove the bolt and camshaft position sensor from the cylinder head cover sub-assembly.

NOTICE:

If the camshaft position sensor has been struck or dropped, replace it.

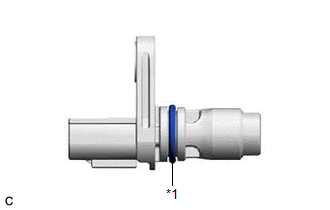

| (c) Perform this procedure only when reusing the camshaft position sensor. (1) Remove the O-ring from the camshaft position sensor. NOTICE: -

Make sure to only remove the O-ring with bare hands.

-

When removing the O-ring, be careful not to damage the O-ring groove of the camshaft position sensor.

-

If the O-ring groove of the camshaft position sensor is damaged, replace the camshaft position sensor with a new one.

| |

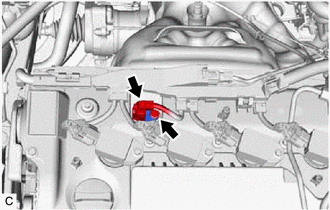

3. REMOVE CAMSHAFT POSITION SENSOR (for Exhaust Side)

(a) Disconnect the camshaft position sensor connector.

| (b) Using an 8 mm socket wrench, remove the bolt and camshaft position sensor from the cylinder head cover sub-assembly. NOTICE: If the camshaft position sensor has been struck or dropped, replace it. | |

| (c) Perform this procedure only when reusing the camshaft position sensor. (1) Remove the O-ring from the camshaft position sensor. NOTICE: -

Make sure to only remove the O-ring with bare hands.

-

When removing the O-ring, be careful not to damage the O-ring groove of the camshaft position sensor.

-

If the O-ring groove of the camshaft position sensor is damaged, replace the camshaft position sensor with a new one.

| |

READ NEXT:

INSTALLATION CAUTION / NOTICE / HINT NOTICE: This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts. Click here

ON-VEHICLE INSPECTION PROCEDURE 1. INSPECT CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY (a) Check Rotation Direction Signal: (1) Connect the Techstream to the DLC3. (2) Turn the engine switch on (IG). (

SEE MORE:

COMPONENTS ILLUSTRATION *A for HV Model *B for Gasoline Model *1 REAR DOOR SCUFF PLATE LH *2 REAR DOOR SCUFF PLATE RH *3 REAR SEAT SIDE GARNISH LH *4 REAR SEAT SIDE GARNISH RH *5 ROOF SIDE INNER GARNISH ASSEMBLY LH *6 ROOF SIDE INNER GARNISH ASSEMBLY RH *7

DESCRIPTION If the manual up and down functions operate normally but the auto up and down functions do not, the power window control system may be in fail-safe mode. If power window initialization has not been performed, the auto up and down functions will not operate. Click here WIRING DIAGRAM C

© 2016-2026 Copyright www.lexguide.net

.gif)

.gif)

.gif)