Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced battery removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream.

Click here |

|||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Control System |

|

|

Pre-collision system |

|||

|

Parking Support Brake System* |

|||

|

Lighting System |

|||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

|

|

|

Panoramic View Monitor System |

|

||

|

Initialize power trunk lid system |

Power Trunk Lid System (for Gasoline Model) |

|

|

NOTICE:

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System)

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

- When replacing the battery, use a new battery of the same dimensions and same capacity or more from the same class at a 20-hour rate.

PROCEDURE

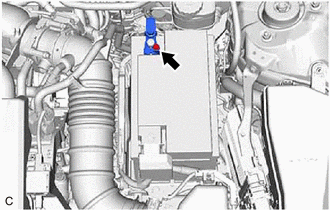

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

|

(a) Loosen the nut, and disconnect the cable from the negative (-) battery terminal. NOTICE: When disconnecting the cable, some systems need to be initialized after the cable is reconnected. Click here |

|

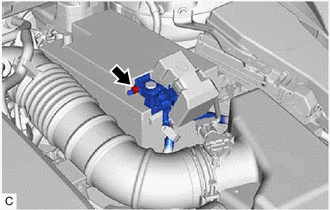

2. REMOVE BATTERY

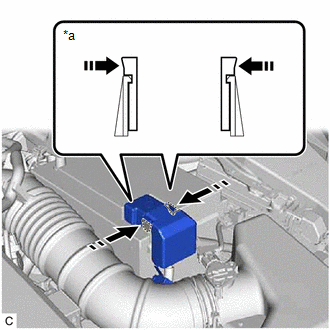

(a) Disengage the 2 claws and remove the battery terminal cap from the positive (+) battery terminal in the order shown in the illustration.

|

*a |

Side View of Claws |

|

Push Battery Terminal Cap Here |

|

Push |

|

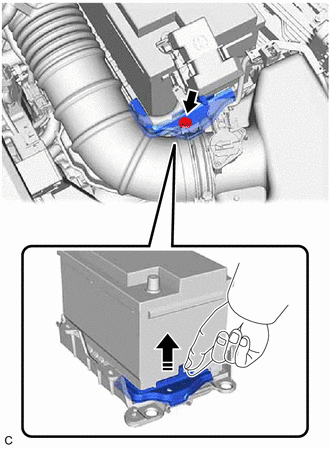

(b) Loosen the nut and disconnect the cable from the positive (+) battery terminal. |

|

(c) Remove the bolt and No. 2 battery clamp from the battery clamp sub-assembly.

|

Remove in this Direction |

(d) Remove the battery from the vehicle.

.gif)