Lexus ES: Registration

REGISTRATION

CAUTION / NOTICE / HINT

NOTICE:

-

When the automatic transaxle assembly is replaced, the transaxle compensation code must be registered to the ECM (proceed to Procedure 1).

After the automatic transaxle assembly is installed, the Quick Response (QR) code label will be positioned where the code cannot be read. Therefore, before installing the automatic transaxle assembly, record the transaxle compensation code or register it using the Techstream.

- When the ECM is replaced, the existing transaxle compensation code must be registered to the new ECM (proceed to Procedure 2).

- Perform Reset Memory (AT initialization) after replacing the automatic transaxle assembly, transmission valve body assembly, any of the solenoid valves or engine assembly.

PROCEDURE

1. INPUT TRANSAXLE COMPENSATION CODE INTO ECM (Procedure 1)

NOTICE:

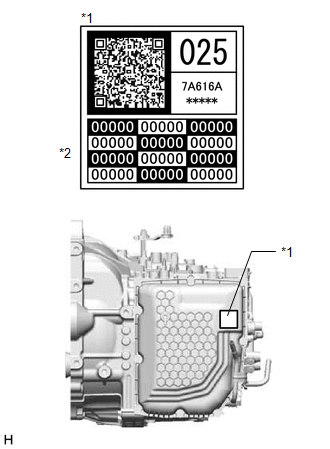

Transaxle compensation codes are unique, 60-digit alphanumeric values printed on a QR code label on the transaxle. If an incorrect transaxle compensation code is registered to the ECM, shift shock may occur.

| (a) Record the transaxle compensation code specified on the QR code label. HINT: The transaxle compensation code is printed on the QR code label. |

|

(b) Make sure the shift lever is in P or N.

(c) Connect the Techstream to the DLC3.

(d) Turn the engine switch on (IG).

NOTICE:

Do not start the engine.

(e) Turn the Techstream on.

(f) Enter the following menus: Powertrain / Transmission / Utility / A/T Code Registration.

Powertrain > Transmission > Utility| Tester Display |

|---|

| A/T Code Registration |

(g) Select "Set Compensation Code".

(h) Register the transaxle compensation code.

(1) Press "Input".

(2) Manually input the transaxle compensation code. The code is a 60-digit alphanumeric value printed on the QR code label. After inputting the code, press "OK".

(i) Check that the transaxle compensation code displayed on the screen is correct by comparing it with the 60-digit alphanumeric value on the QR code label.

NOTICE:

If an incorrect transaxle compensation code is registered to the ECM, shift shock may occur.

(j) Press "NEXT" to register the transaxle compensation code to the ECM.

NOTICE:

- If the registration process fails, the transaxle compensation code may be incorrect. Check the transaxle compensation code again.

- If the attempted transaxle compensation code is correct, a problem with the wire harness or a bad connection with the DLC3 may cause registration failure. Check the wire harness and the DLC3 connection. If no problem is found, the ECM may be malfunctioning. Check the ECM and repeat this operation.

2. TRANSFER TRANSAXLE COMPENSATION CODE (Procedure 2)

NOTICE:

Transaxle compensation codes are unique, 60-digit alphanumeric values printed on a QR code label on the transaxle. If an incorrect transaxle compensation code is registered to the ECM, shift shock may occur.

HINT:

The following operation is available for use when the ECM that is being replaced can still transmit its registered transaxle compensation code to the Techstream.

(a) Read the transaxle compensation code.

(1) Make sure the shift lever is in P or N.

(2) Connect the Techstream to the DLC3.

(3) Turn the engine switch on (IG).

NOTICE:

Do not start the engine

(4) Turn the Techstream on.

(5) Enter the following menus: Powertrain / Transmission / Utility / A/T Code Registration.

Powertrain > Transmission > Utility| Tester Display |

|---|

| A/T Code Registration |

(6) Select "Read Compensation Code".

(7) Press "Save".

(8) Press "Save" or "Overwrite".

(9) Press "Exit".

NOTICE:

Do not use the code printed on the transaxle QR code label even if the transaxle compensation code cannot be read using the Techstream. The code printed on an in-service transaxle may not match its current characteristics. Replace the ECM with a new one and perform a road test to allow the ECM to learn the transaxle characteristics.

(10) Turn the engine switch off.

(b) Replace the ECM.

(c) Register the transaxle compensation code.

(1) Turn the engine switch on (IG).

NOTICE:

Do not start the engine.

(2) Turn the Techstream on.

(3) Enter the following menus: Powertrain / Transmission / Utility / A/T Code Registration.

Powertrain > Transmission > Utility| Tester Display |

|---|

| A/T Code Registration |

(4) Select "Set Compensation Code".

(5) Press "Open".

(6) Press "Open" again to proceed.

(7) Press "EXIT".