Lexus ES: Shift Paddle Switch Circuit

DESCRIPTION

Moving the shift lever to S enables the shift range to be selected. The shift range can be selected by operating the "+" or "-" shift paddle switch.

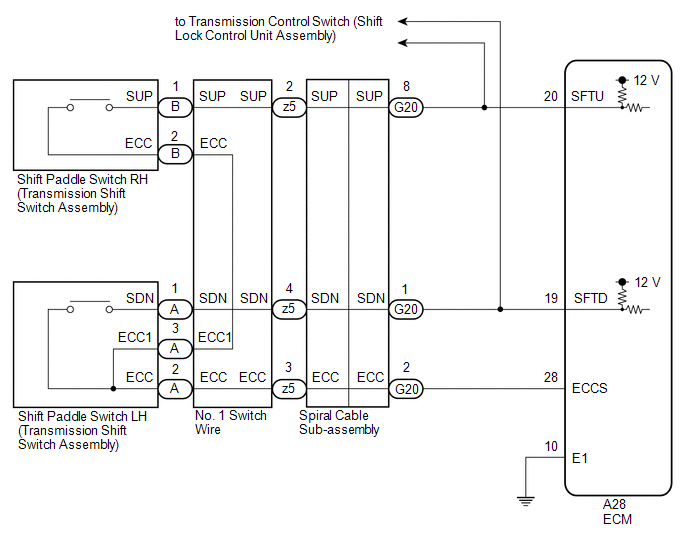

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here .gif)

.gif)

PROCEDURE

| 1. | READ VALUE USING TECHSTREAM (SPORT SHIFT SWITCH STATUS) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Data List.

(e) According to the display on the Techstream, read the Data List.

Powertrain > Engine > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Sport Shift Up SW | Sport shift up switch status | ON or OFF |

| - |

| Sport Shift Down SW | Sport shift down switch status | ON or OFF |

| - |

| Tester Display |

|---|

| Sport Shift Up SW |

| Sport Shift Down SW |

| Result | Proceed to |

|---|---|

| Data List values are normal | A |

| Data List values are not normal | B |

| A | .gif) | CHECK FOR INTERMITTENT PROBLEMS |

|

| 2. | CHECK HARNESS AND CONNECTOR (SHIFT PADDLE SWITCH CIRCUIT) |

(a) Disconnect the A28 ECM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A28-20 (SFTU) - A28-28 (ECCS) | "+" (Up shift) shift paddle switch operated and held | Below 2.5 Ω |

| "+" (Up shift) shift paddle switch not operated | 1 MΩ or higher | |

| A28-19 (SFTD) - A28-28 (ECCS) | "-" (Down shift) shift paddle switch operated and held | Below 2.5 Ω |

| "-" (Down shift) shift paddle switch not operated | 1 MΩ or higher |

| NG | .gif) | GO TO STEP 4 |

|

| 3. | CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND) |

(a) Disconnect the A28 ECM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A28-10 (E1) - Body ground | Always | Below 1 Ω |

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - BODY GROUND) |

| 4. | CHECK HARNESS AND CONNECTOR (SPIRAL CABLE SUB-ASSEMBLY - ECM) |

(a) Disconnect the G20 spiral cable sub-assembly connector.

(b) Disconnect the A28 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A28-20 (SFTU) - G20-8 (SUP) | Always | Below 1 Ω |

| A28-19 (SFTD) - G20-1 (SDN) | Always | Below 1 Ω |

| A28-28 (ECCS) - G20-2 (ECC) | Always | Below 1 Ω |

| A28-20 (SFTU) or G20-8 (SUP) - Body ground | Always | 10 kΩ or higher |

| A28-19 (SFTD) or G20-1 (SDN) - Body ground | Always | 10 kΩ or higher |

| A28-28 (ECCS) or G20-2 (ECC) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (SPIRAL CABLE SUB-ASSEMBLY - ECM) |

|

| 5. | INSPECT SPIRAL CABLE SUB-ASSEMBLY |

(a) Inspect the spiral cable sub-assembly.

Click here .gif)

| NG | .gif) | REPLACE SPIRAL CABLE SUB-ASSEMBLY |

|

| 6. | INSPECT SHIFT PADDLE SWITCH LH (TRANSMISSION SHIFT SWITCH ASSEMBLY) |

| (a) Remove the shift paddle switch LH (transmission shift switch assembly). Click here |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A-1 (SDN) - A-2 (ECC) | "-" (Down shift) shift paddle switch operated and held | Below 2.5 Ω |

| "-" (Down shift) shift paddle switch not operated | 1 MΩ or higher | |

| A-1 (SDN) - A-3 (ECC1) | "-" (Down shift) shift paddle switch operated and held | Below 2.5 Ω |

| "-" (Down shift) shift paddle switch not operated | 1 MΩ or higher |

| NG | .gif) | REPLACE SHIFT PADDLE SWITCH LH (TRANSMISSION SHIFT SWITCH ASSEMBLY) |

|

| 7. | INSPECT SHIFT PADDLE SWITCH RH (TRANSMISSION SHIFT SWITCH ASSEMBLY) |

| (a) Remove the shift paddle switch RH (transmission shift switch assembly). Click here |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| B-1 (SUP) - B-2 (ECC) | "+" (Up shift) shift paddle switch operated and held | Below 2.5 Ω |

| "+" (Up shift) shift paddle switch not operated | 1 MΩ or higher |

| NG | .gif) | REPLACE SHIFT PADDLE SWITCH RH (TRANSMISSION SHIFT SWITCH ASSEMBLY) |

|

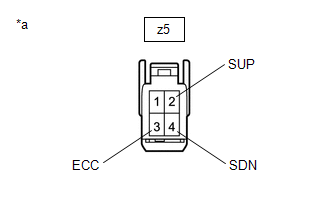

| 8. | INSPECT NO. 1 SWITCH WIRE |

| (a) Install the transmission shift switch assembly. Click here |

|

(b) Disconnect the z5 No. 1 switch wire connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| z5-2 (SUP) - z5-3 (ECC) | "+" (Up shift) shift paddle switch operated and held | Below 2.5 Ω |

| "+" (Up shift) shift paddle switch not operated | 1 MΩ or higher | |

| z5-4 (SDN) - z5-3 (ECC) | "-" (Down shift) shift paddle switch operated and held | Below 2.5 Ω |

| "-" (Down shift) shift paddle switch not operated | 1 MΩ or higher |

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) | REPLACE NO. 1 SWITCH WIRE |

.gif)

.png)

.png)