Lexus ES: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

PROCEDURE

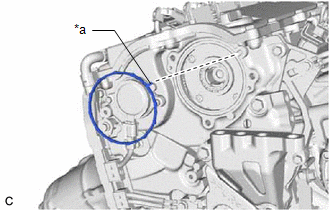

1. INSTALL CAM TIMING CONTROL MOTOR O-RING

| (a) Install a new cam timing control motor O-ring to the No. 2 timing gear cover assembly with the protrusion of the cam timing control motor O-ring oriented as shown in the illustration. | |

2. INSTALL CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

HINT:

Perform "Inspection After Repair" after removing and installing, or replacing the cam timing control motor with EDU assembly.

Click here .gif)

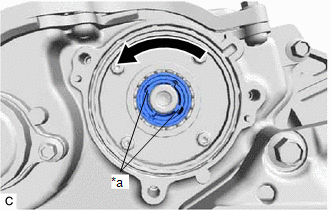

| (a) Turn the cutout of the camshaft timing gear assembly eccentric shaft counterclockwise by hand, and set it to the maximum retard angle position. HINT: -

If a camshaft lobe is opening a valve, the eccentric shaft will be difficult to turn.

-

When the cutout of the camshaft timing gear assembly eccentric shaft cannot be turned any farther, it is set to the maximum retard angle.

| |

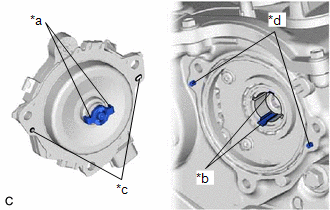

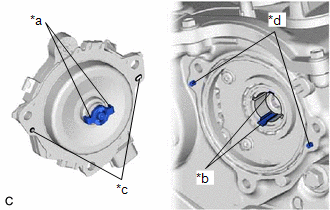

| (b) Install the cam timing control motor with EDU assembly to the No. 2 timing gear cover assembly. NOTICE: -

When installing, align the joints of the cam timing control motor with EDU assembly with the cutouts of the camshaft timing gear assembly eccentric shaft.

-

Align the pin holes of the cam timing control motor with EDU assembly with the knock pins of the No. 2 timing gear cover assembly when installing the cam timing control motor with EDU assembly.

-

Make sure the contact surface of the cam timing control motor with EDU assembly (the surface that contacts the No. 2 timing gear cover assembly) is free of foreign matter.

-

When installing the cam timing control motor with EDU assembly, do not use excessive force.

-

If the cam timing control motor with EDU assembly has been struck or dropped, replace it.

-

Do not disassemble the cam timing control motor with EDU assembly. If disassembled, replace it.

|  | | *a | Joint | | *b | Cutout | | *c | Pin Hole | | *d | Knock Pin | | |

(c) Install the 3 bolts.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(d) Connect the cam timing control motor with EDU assembly connector.

3. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Click here .gif)

4. INSPECT FOR ENGINE OIL LEAK

Click here .gif)

.gif)

5. INSTALL NO. 2 ENGINE COVER

Click here .gif)

.gif)

6. INSTALL NO. 3 BRAKE TUBE CLAMP

Click here .gif)

7. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

Click here .gif)

.gif)

8. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after removing and installing, or replacing the cam timing control motor with EDU assembly.

Click here .gif)

READ NEXT:

ComponentsCOMPONENTS ILLUSTRATION *1 CRANKSHAFT POSITION SENSOR *2 O-RING N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part InstallationINSTALLATION CAUTION / NOT

InstallationINSTALLATION PROCEDURE 1. INSTALL NO. 2 ECM BRACKET (a) Install the No. 2 ECM bracket to the ECM with the 2 screws. Torque: 4.5 N·m {46 kgf·cm, 40 in·lbf} 2. INSTALL NO. 1 ECM BRACKET

ComponentsCOMPONENTS ILLUSTRATION *1 ENGINE COOLANT TEMPERATURE SENSOR - - ● Non-reusable part - - RemovalREMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustmen

SEE MORE:

ON-VEHICLE INSPECTION PROCEDURE 1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY (a) for RH Side (1) Operate the windshield wiper motor assembly. (2) Stop the windshield wiper motor assembly operation. (3) Check the automatic stop (park) position. HINT: After the front wiper motor is stopped, check the

COMPONENTS ILLUSTRATION *1 REAR DIFFERENTIAL CARRIER ASSEMBLY *2 WIRE HARNESS CLAMP BRACKET *3 REAR UPPER DIFFERENTIAL MOUNT STOPPER *4 REAR LOWER DIFFERENTIAL MOUNT STOPPER *5 REAR SUSPENSION MEMBER SUB-ASSEMBLY - - Tightening torque for "Major areas involving b

© 2016-2026 Copyright www.lexguide.net

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)

.gif)