Lexus ES: Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE COVER BRACKET

(a) Install the engine cover bracket to the cylinder head cover sub-assembly LH with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

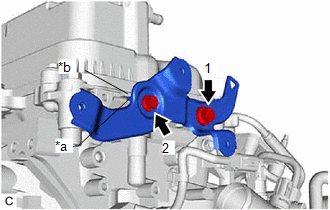

2. INSTALL WATER FILLER BRACKET

| (a) Temporarily install the water filler bracket to the camshaft housing sub-assembly LH with the 2 bolts. |

|

(b) Fully tighten the 2 bolts in the order shown in the illustration.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

NOTICE:

Make sure that the stopper of the water filler bracket is pressed against the protrusion of the camshaft housing sub-assembly LH when fully tightening the 2 bolts.

3. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the wire harness clamp bracket to the camshaft housing sub-assembly with the bolt.

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

(b) Install the wire harness clamp bracket to the camshaft housing sub-assembly LH with the bolt.

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

4. INSTALL DRIVE SHAFT BEARING BRACKET

(a) Install the drive shaft bearing bracket to the cylinder block sub-assembly with the 3 bolts.

Torque:

63.7 N·m {650 kgf·cm, 47 ft·lbf}

NOTICE:

Make sure that there is no oil on the threads of the bolts.

5. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

(a) Install a new engine oil level dipstick guide O-ring to the engine oil level dipstick guide.

(b) Apply a light coat of engine oil to the engine oil level dipstick guide O-ring.

(c) Insert the engine oil level dipstick guide end into the oil pan sub-assembly.

(d) Install the engine oil level dipstick guide to the camshaft housing sub-assembly LH with the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(e) Install the engine oil level dipstick to the engine oil level dipstick guide.

6. INSTALL WATER PUMP PULLEY

Click here .gif)

7. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(a) Install the V-ribbed belt tensioner assembly with the 2 bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

8. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

Click here .gif)

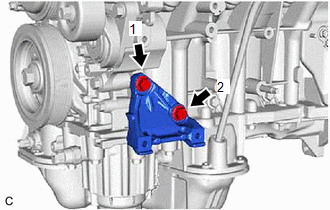

9. INSTALL NO. 1 COMPRESSOR MOUNTING BRACKET

| (a) Temporarily install the No. 1 compressor mounting bracket to the cylinder block sub-assembly with the 2 bolts. |

|

(b) Fully tighten the 2 bolts in the order shown in the illustration.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

10. INSTALL COMPRESSOR ASSEMBLY WITH MAGNETIC CLUTCH

Click here .gif)

11. INSTALL GENERATOR ASSEMBLY

Click here .gif)

12. INSTALL V-RIBBED BELT

Click here .gif)

13. INSTALL NO. 2 VENTILATION HOSE

(a) Install the No. 2 ventilation hose to the cylinder head cover sub-assembly and slide the clip to secure it.

14. INSTALL VENTILATION HOSE

(a) Install the ventilation hose to the PCV valve (ventilation valve sub-assembly) and slide the clip to secure it.

15. INSTALL NO. 2 WATER BY-PASS HOSE

(a) Install the No. 2 water by-pass hose to the water outlet and slide the clip to secure it.

16. INSTALL NO. 3 WATER BY-PASS HOSE

(a) Install the No. 3 water by-pass hose to the water inlet pipe and slide the clip to secure it.

17. INSTALL VACUUM PUMP ASSEMBLY

-

for TMMK Made:

Click here

.gif)

-

for TMC Made:

Click here

.gif)

18. INSTALL IGNITION COIL ASSEMBLY

Click here .gif)

19. INSTALL SENSOR WIRE

(a) Engage the 2 clamps and install the sensor wire with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

20. INSTALL KNOCK CONTROL SENSOR

Click here .gif)