Lexus ES: Inspection

INSPECTION

PROCEDURE

1. INSPECT LEVEL WARNING SWITCH ASSEMBLY

HINT:

This check should be performed with the level warning switch assembly installed to the washer jar.

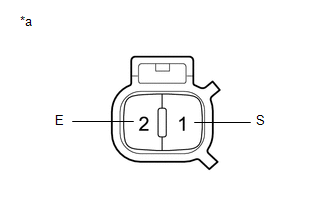

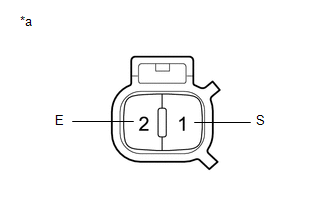

| (a) Fill the washer jar with washer fluid. |  | | *a | Component without harness connected (Level Warning Switch Assembly) | | |

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| 1 (S) - 2 (E) | Fluid volume is 600 to 800 cc (36.6 to 48.8 cu. in.) or higher* | 10 kΩ or higher |

| Fluid volume is 600 to 800 cc (36.6 to 48.8 cu. in.) or lower* | Below 1 Ω |

HINT:

*: The level warning switch assembly begins operating when the fluid volume is 600 to 800 cc (36.6 to 48.8 cu. in.) depending on the vehicle condition.

If the result is not as specified, replace the level warning switch assembly.

READ NEXT:

INSTALLATION PROCEDURE 1. INSTALL LEVEL WARNING SWITCH ASSEMBLY (a) Install the level warning switch assembly as shown in the illustration. *a Protrusion *b Marking Install in this

COMPONENTS ILLUSTRATION *1 FRONT FENDER LINER RETAINER *2 FRONT WHEEL OPENING EXTENSION PAD RH *3 PIN HOLD CLIP *4 REAR FENDER SPLASH SHIELD SUB-ASSEMBLY RH *5 WINDSHIELD WAS

SEE MORE:

DESCRIPTION The skid control ECU (brake actuator assembly) receives shift position signals from the ECM via CAN communication to control the electric parking brake system AUTO function (IG-OFF linked function). The electric parking brake system AUTO function (IG-OFF linked function) is automatically

PRECAUTION PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL NOTICE: When disconnecting the cable from the negative (-) battery terminal, initialize the following systems after the cable is reconnected. System Name See Procedure Lane Control System (for Gasoline Model)

© 2016-2026 Copyright www.lexguide.net