Lexus ES: Inspection

INSPECTION

PROCEDURE

1. INSPECT OUTER MIRROR RH

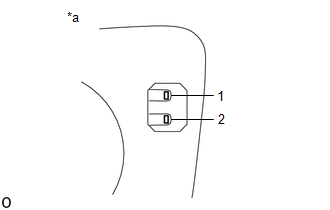

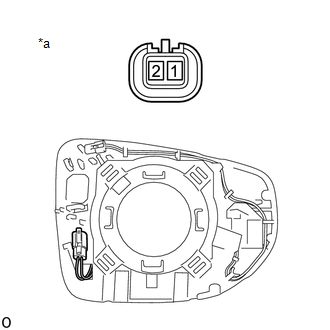

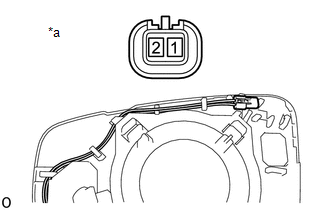

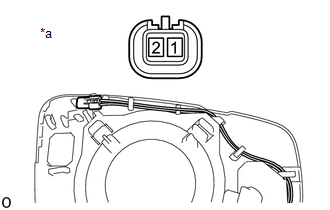

| (a) Check the outer mirror heater operation. (1) Measure the resistance according to the value(s) in the table below. Standard Resistance: | Tester Connection | Condition | Specified Condition | | 1 - 2 | 25°C (77°F) | 3.8 to 5.8 Ω | If the result is not as specified, replace the outer mirror RH. |  | | *a | Component without harness connected (Outer Mirror RH) | | |

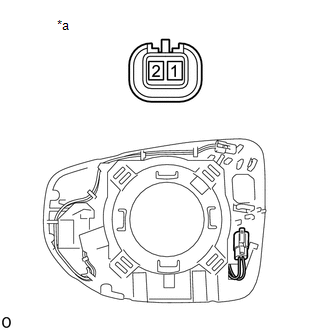

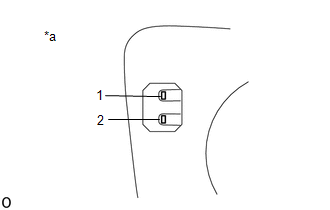

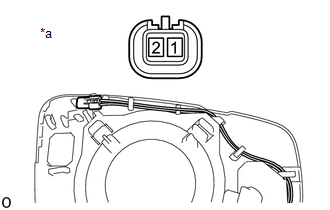

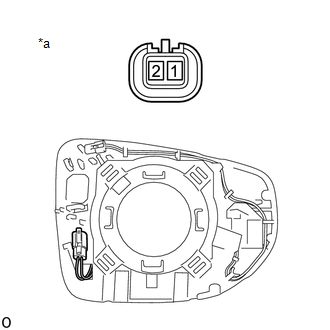

| (b) Check EC mirror operation. (1) Connect a new 1.5 V dry-cell battery. (2) Apply 1.5 V dry-cell battery voltage to the terminals of the connector, and check that the EC mirror operation. NOTICE: Do not apply a voltage of more than 1.5 V. OK: | Tester Connection | Specified Condition | | 1.5 V battery positive (+) → Terminal 1 1.5 V battery negative (-) → Terminal 2 | Mirror surface becomes dark | If the result is not as specified, replace the outer mirror RH. |  | | *a | Component without harness connected (Outer Mirror RH) | | |

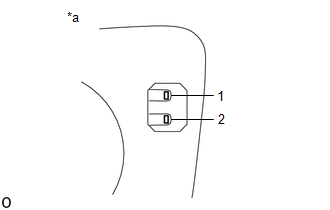

(c) Check the operation of the outer rear view mirror indicator. (w/ Blind Spot Monitor System)

NOTICE:

Do not apply a voltage of more than 6 V.

(1) Connect 4 new 1.5 V dry-cell batteries in series.

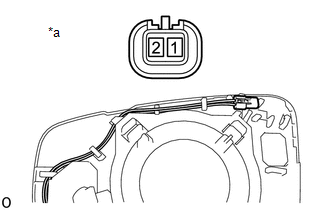

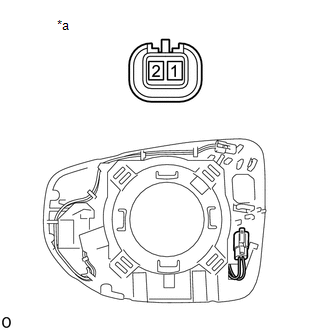

| (2) Apply 6 V battery voltage to the terminals of the connector, and check that the outer rear view mirror indicator comes on. OK: | Tester Connection | Specified Condition | | 6 V battery positive (+) → Terminal 1 6 V battery negative (-) → Terminal 2 | Outer rear view mirror indicator comes on | If the result is not as specified, replace the outer mirror RH. |  | | *a | Component without harness connected (Outer Mirror RH) | | |

2. INSPECT OUTER MIRROR LH

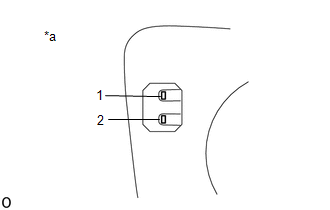

| (a) Check the outer mirror heater operation. (1) Measure the resistance according to the value(s) in the table below. Standard Resistance: | Tester Connection | Condition | Specified Condition | | 1 - 2 | 25°C (77°F) | 3.8 to 5.8 Ω | If the result is not as specified, replace the outer mirror LH. |  | | *a | Component without harness connected (Outer Mirror LH) | | |

| (b) Check EC mirror operation. (1) Connect a new 1.5 V dry-cell battery. (2) Apply 1.5 V dry-cell battery voltage to the terminals of the connector, and check that the EC mirror operation. NOTICE: Do not apply a voltage of more than 1.5 V. OK: | Tester Connection | Specified Condition | | 1.5 V battery positive (+) → Terminal 1 1.5 V battery negative (-) → Terminal 2 | Mirror surface becomes dark | If the result is not as specified, replace the outer mirror LH. |  | | *a | Component without harness connected (Outer Mirror LH) | | |

(c) Check the operation of the outer rear view mirror indicator. (w/ Blind Spot Monitor System)

NOTICE:

Do not apply a voltage of more than 6 V.

(1) Connect 4 new 1.5 V dry-cell batteries in series.

| (2) Apply 6 V battery voltage to the terminals of the connector, and check that the outer rear view mirror indicator comes on. OK: | Tester Connection | Specified Condition | | 6 V battery positive (+) → Terminal 1 6 V battery negative (-) → Terminal 2 | Outer rear view mirror indicator comes on | If the result is not as specified, replace the outer mirror LH. |  | | *a | Component without harness connected (Outer Mirror LH) | | |

READ NEXT:

INSTALLATION CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH side and LH side.

The following procedure is for the LH side.

PROCEDURE 1. INSTALL OUTER MIRROR (a) w/o Blind Spot

PRECAUTION PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL NOTICE: When disconnecting the cable from the negative (-) battery terminal, initialize the following systems after the cab

SEE MORE:

COMPONENTS ILLUSTRATION *1 BATTERY SERVICE HOLE COVER *2 SERVICE PLUG GRIP ILLUSTRATION *1 CONNECTOR COVER ASSEMBLY *2 ENGINE ROOM MAIN WIRE Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf)

ComponentsCOMPONENTS ILLUSTRATION *1 DRIVE MODE SELECT SWITCH (COMBINATION SWITCH ASSEMBLY) - - RemovalREMOVAL PROCEDURE 1. REMOVE DRIVE MODE SELECT SWITCH (COMBINATION SWITCH ASSEMBLY) Click here InspectionINSPECTION PROCEDURE 1. INSPECT DRIVE MODE SELECT SWITCH (COMBINATION SWITC

© 2016-2026 Copyright www.lexguide.net