Lexus ES: Inspection

INSPECTION

PROCEDURE

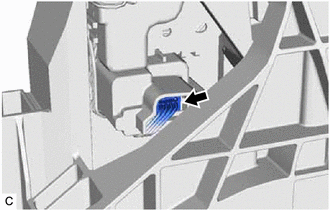

1. INSPECT SHIFT LOCK CONTROL ECU

HINT:

If the results of the following inspections are as specified but a malfunction has occurred, replace the shift lock control unit assembly.

(a) Inspect wire harness:

| (1) Disconnect the shift lock control ECU connector. | |

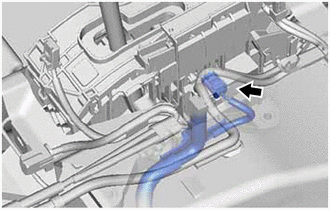

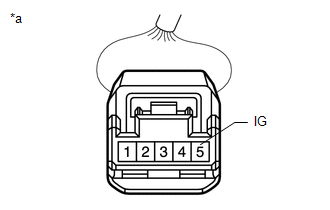

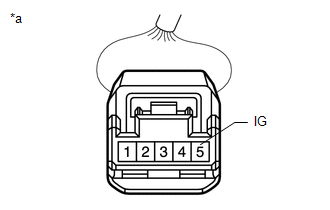

| (2) Measure the voltage according to the value(s) in the table below. Standard Voltage: | Tester Connection | Condition | Specified Condition | | 5 (IG) - Body ground | Power switch on (IG) | 11 to 14 V | | Power switch off | Below 1 V | If the result is not as specified, repair or replace the shift lock control ECU wire harness. |  | | *a | Front view of wire harness connector (to Shift Lock Control ECU) | | |

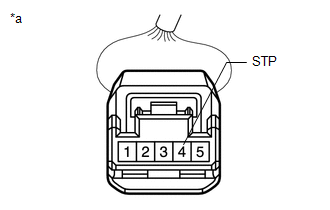

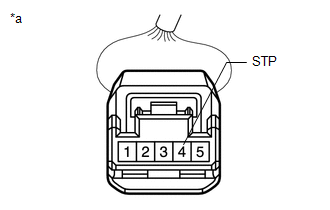

| (3) Measure the voltage according to the value(s) in the table below. Standard Voltage: | Tester Connection | Condition | Specified Condition | | 4 (STP) - Body ground | Power switch on (IG), brake pedal depressed | 11 to 14 V | | Power switch on (IG), brake pedal released | Below 1 V | If the result is not as specified, repair or replace the wire harness or connector or replace the hybrid vehicle control ECU assembly. |  | | *a | Front view of wire harness connector (to Shift Lock Control ECU) | | |

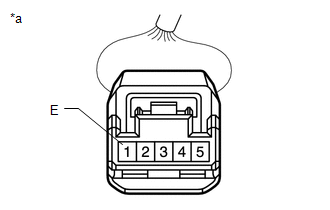

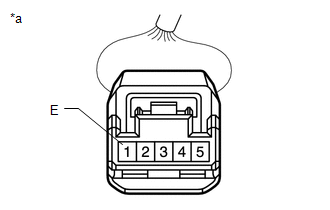

| (4) Measure the resistance according to the value(s) in the table below. Standard Resistance: | Tester Connection | Condition | Specified Condition | | 1 (E) - Body ground | Always | Below 1 Ω | If the result is not as specified, repair or replace the shift lock control ECU wire harness. |  | | *a | Front view of wire harness connector (to Shift Lock Control ECU) | | |

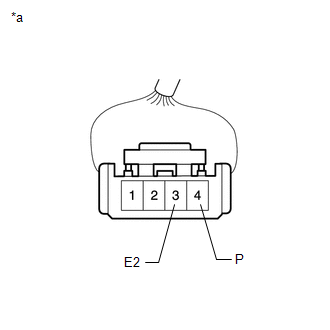

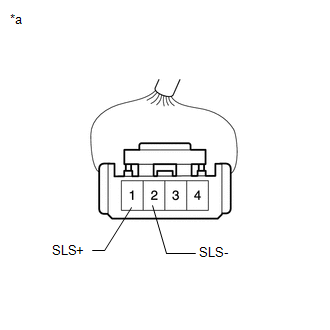

(b) Inspect shift lock solenoid:

| (1) Disconnect the shift lock solenoid connector. | |

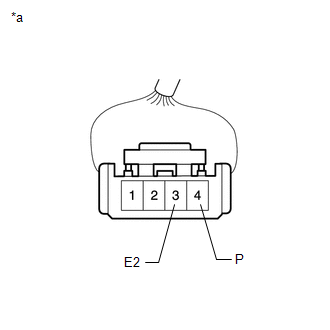

| (2) Measure the resistance according to the value(s) in the table below. Standard Resistance: | Tester Connection | Condition | Specified Condition | | 4 (P) - 3 (E2) | Shift lever in P | 10 kΩ or higher | | Shift lever not in P | Below 1 Ω | If the result is not as specified, replace the shift lock control unit assembly. |  | | *a | Front view of wire harness connector (to Shift Lock Solenoid) | | |

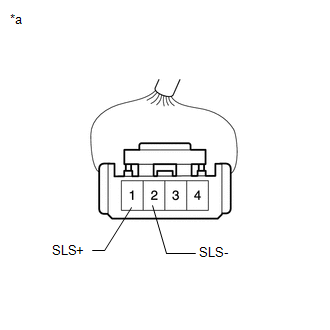

| (3) Measure the resistance according to the value(s) in the table below. Standard Resistance: | Tester Connection | Condition | Specified Condition | | 1 (SLS+) - 2 (SLS-) | Always | 112 Ω | If the result is not as specified, replace the shift lock control unit assembly. |  | | *a | Front view of wire harness connector (to Shift Lock Solenoid) | | |

2. INSPECT TRANSMISSION CONTROL SWITCH

| (a) Disconnect the transmission control switch connector. | |

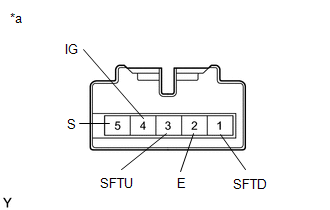

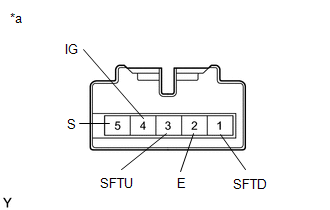

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance: | Tester Connection | Condition | Specified Condition | | 4 (IG) - 5 (S) | Shift lever in S, "+" or "-" | Below 1 Ω | | Shift lever not in S, "+" or "-" | 10 kΩ or higher | | 3 (SFTU) - 2 (E) | Shift lever held in "+" (Up-shift) | Below 1 Ω | | Shift lever not held in "+" (Up-shift) | 10 kΩ or higher | | 1 (SFTD) - 2 (E) | Shift lever held in "-" (Down-shift) | Below 1 Ω | | Shift lever not held in "-" (Down-shift) | 10 kΩ or higher | If the result is not as specified, replace the shift lock control unit assembly. |  | | *a | Component without harness connected (Transmission Control Switch (Transmission Floor Shift Assembly)) | | |

READ NEXT:

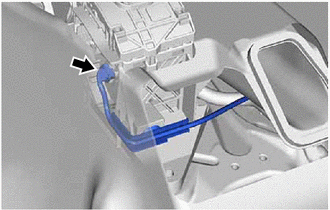

INSTALLATION PROCEDURE 1. INSTALL TRANSMISSION FLOOR SHIFT ASSEMBLY (a) Engage the clamp to connect the wire harness to the transmission floor shift assembly. (b) Connect the shift lock control ECU co

ON-VEHICLE INSPECTION PROCEDURE 1. SECURE VEHICLE (a) Fully apply the parking brake and chock a wheel. CAUTION:

Make sure to apply the parking brake and chock a wheel before performing this procedu

REASSEMBLY PROCEDURE 1. INSTALL LOWER POSITION INDICATOR HOUSING (a) Engage the 4 claws and 2 guides to install the lower position indicator housing to the shift lock control unit assembly. NOTICE:

SEE MORE:

PRECAUTION PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL NOTICE: When disconnecting the cable from the negative (-) auxiliary battery terminal, initialize the following systems after the cable is reconnected. System Name See Procedure Lane Control System (for H

SYSTEM DESCRIPTION SLIDING ROOF SYSTEM DESCRIPTION (a) The sliding roof system controls the sliding roof operation using the sliding roof ECU (sliding roof drive gear sub-assembly). Operating the sliding roof switch (map light sub-assembly) results in electrical power being transmitted to the slidin

© 2016-2026 Copyright www.lexguide.net