Lexus ES: Inspection

INSPECTION

PROCEDURE

1. INSPECT BRAKE ACTUATOR ASSEMBLY

(a) Inspect the solenoid circuit.

(1) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

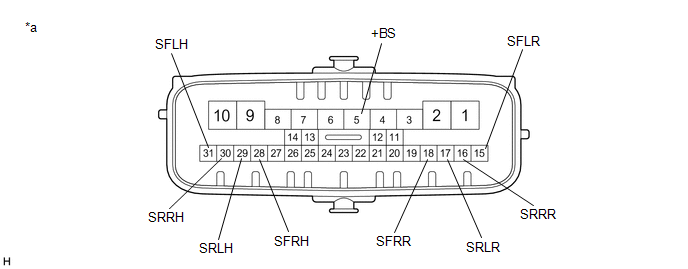

| *a | Component without harness connected (Brake Actuator Assembly) | - | - |

(2) Disconnect the brake actuator assembly connector.

(3) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(4) Measure the resistance according to the value(s) in the table below.

HINT:

- Check the brake actuator assembly when it is cooled down.

- If the result is not as specified, replace the brake actuator assembly.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 5 (+BS) - 28 (SFRH) | Always | 6.4 to 7.0 Ω |

| 5 (+BS) - 31 (SFLH) | Always | 6.4 to 7.0 Ω |

| 5 (+BS) - 30 (SRRH) | Always | 6.4 to 7.0 Ω |

| 5 (+BS) - 29 (SRLH) | Always | 6.4 to 7.0 Ω |

| 5 (+BS) - 18 (SFRR) | Always | 5.1 to 5.7 Ω |

| 5 (+BS) - 15 (SFLR) | Always | 5.1 to 5.7 Ω |

| 5 (+BS) - 16 (SRRR) | Always | 5.1 to 5.7 Ω |

| 5 (+BS) - 17 (SRLR) | Always | 5.1 to 5.7 Ω |