Lexus ES: Reverse Signal Circuit

DESCRIPTION

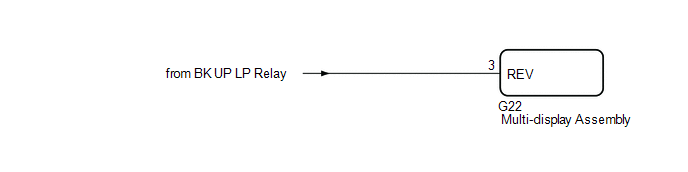

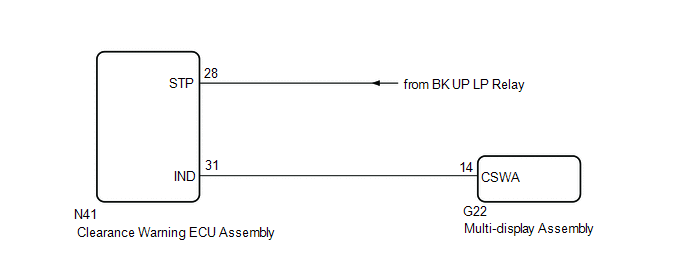

The multi-display receives a reverse signal from the BK UP LP relay*1 or clearance warning ECU assembly*2.

- *1: w/o Parking Support Alert System

- *2: w/ Parking Support Alert System

WIRING DIAGRAM

for 8 inch display for 12.3 inch display w/ Parking Support Alert System

for 12.3 inch display w/ Parking Support Alert System

CAUTION / NOTICE / HINT

NOTICE:

-

When "!" mark is displayed on the multi-display assembly after disconnecting the cable from the negative (-) auxiliary battery terminal, correct the steering angle neutral point.

Click here

.gif)

-

Depending on the parts that are replaced or operations that are performed during vehicle inspection or maintenance, calibration of other systems as well as the parking assist monitor system may be needed.

Click here

.gif)

PROCEDURE

| 1. | CHECK BACK-UP LIGHT |

(a) Check that the back-up light comes on.

OK:

The back-up light comes on.

| Result | Proceed to |

|---|---|

| OK (for 8 inch display) | A |

| OK (for 12.3 inch display w/ Parking Support Alert System) | B |

| NG | C |

| B | .gif) | GO TO STEP 3 |

| C | .gif) | GO TO LIGHTING SYSTEM (EXT) |

|

| 2. | CHECK HARNESS AND CONNECTOR (REVERSE SIGNAL) |

(a) Disconnect the G22 multi-display assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| G22-3 (REV) - Body ground | Power switch on (IG) Shift lever in R | 11 to 14 V |

| G22-3 (REV) - Body ground | Power switch on (IG) Shift lever not in R | Below 1 V |

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 3. | CHECK HARNESS AND CONNECTOR (REVERSE SIGNAL) |

(a) Disconnect the N41 clearance warning ECU assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N41-28 (STP) - Body ground | Power switch on (IG) Shift lever in R | 8 V or higher |

| N41-28 (STP) - Body ground | Power switch on (IG) Shift lever not in R | Below 3 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. | CHECK HARNESS AND CONNECTOR (CLEARANCE WARNING ECU ASSEMBLY - MULTI-DISPLAY ASSEMBLY) |

(a) Disconnect the N41 clearance warning ECU assembly connector.

(b) Disconnect the G22 multi-display assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N41-31 (IND) - G22-14 (CSWA) | Always | Below 1 Ω |

| N41-31 (IND) or G22-14 (CSWA) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. | INSPECT CLEARANCE WARNING ECU ASSEMBLY |

| (a) Connect the N41 clearance warning ECU assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N41-31 (IND) - Body ground | Power switch on (IG) Shift lever in R | Below 3 V |

| N41-31 (IND) - Body ground | Power switch on (IG) Shift lever not in R | 8 V or higher |

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) | REPLACE CLEARANCE WARNING ECU ASSEMBLY |

.gif)

.png)