Lexus ES: Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during diaphragm oil seal removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| *1: for LED Type Turn Signal Light | |||

| Rear wheel alignment adjustment |

|

| |

| Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

|

| |

| Rear television camera assembly optical axis adjustment (Back camera position setting) | Parking Assist Monitor System | | |

| Panoramic View Monitor System | | |

| Perform headlight ECU sub-assembly LH initialization*1 | Lighting System | | |

| Rear height control sensor sub-assembly LH | Perform headlight ECU sub-assembly LH initialization*1 | Lighting System | |

| Exhaust system parts | Inspection after repair |

| |

CAUTION:

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

.png)

PROCEDURE

1. REMOVE REAR DIFFERENTIAL CARRIER ASSEMBLY

Click here .gif)

2. REMOVE REAR NO. 1 DIFFERENTIAL SUPPORT

Click here .gif)

3. REMOVE REAR NO. 2 DIFFERENTIAL SUPPORT

Click here .gif)

4. REMOVE TRANSMISSION COUPLING ASSEMBLY

Click here .gif)

5. REMOVE TRANSMISSION COUPLING CONICAL SPRING WASHER

Click here .gif)

6. REMOVE TRANSMISSION COUPLING SHIM

Click here .gif)

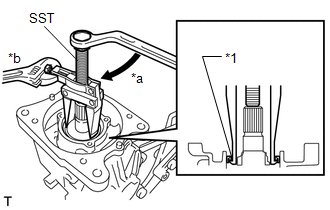

7. REMOVE DIAPHRAGM OIL SEAL

| (a) Using SST, remove the diaphragm oil seal from the rear differential carrier sub-assembly. SST: 09308-10010 |

|

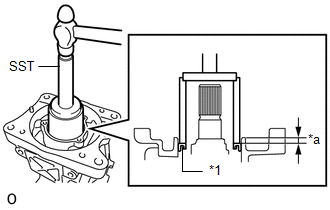

8. INSTALL DIAPHRAGM OIL SEAL

(a) Coat the lip of a new diaphragm oil seal with MP grease.

| (b) Using SST and a hammer, tap the diaphragm oil seal into the rear differential carrier sub-assembly until it reaches the standard value. SST: 09710-30021 09710-03121 SST: 09950-60011 09951-00570 SST: 09950-70010 09951-07100 Standard distance: 6.5 to 7.5 mm (0.256 to 0.295 in.) (from the edge of the differential carrier sub-assembly) NOTICE:

|

|

9. INSTALL TRANSMISSION COUPLING SHIM

Click here .gif)

10. INSTALL TRANSMISSION COUPLING CONICAL SPRING WASHER

Click here .gif)

11. INSTALL TRANSMISSION COUPLING ASSEMBLY

Click here .gif)

12. INSTALL REAR NO. 1 DIFFERENTIAL SUPPORT

Click here .gif)

13. INSTALL REAR NO. 2 DIFFERENTIAL SUPPORT

Click here .gif)

14. INSTALL REAR DIFFERENTIAL CARRIER ASSEMBLY

Click here .gif)