Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fuel main valve assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

|

*: When performing learning using the Techstream.

Click here | |||

| Auxiliary battery terminal is disconnected/reconnected | Perform steering sensor zero point calibration | Lane Control System (for HV Model) | |

| Pre-collision System (for HV Model) | |||

| Parking Support Brake System (for HV Model)* | |||

| Lighting System (for HV Model) | |||

| Memorize steering angle neutral point | Parking Assist Monitor System (for HV Model) | | |

| Panoramic View Monitor System (for HV Model) | | ||

| Initialize power trunk lid system | Power Trunk Lid System (for HV Model) | | |

CAUTION:

-

Never perform work on fuel system components near any possible ignition sources.

.png)

- Vaporized fuel could ignite, resulting in a serious accident.

-

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) auxiliary battery terminal.

.png)

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

NOTICE:

- After the power switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the power switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) auxiliary battery terminal. (for Audio and Visual System)

- After the power switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the power switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) auxiliary battery terminal. (for Navigation System)

PROCEDURE

1. REMOVE FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

Click here .gif)

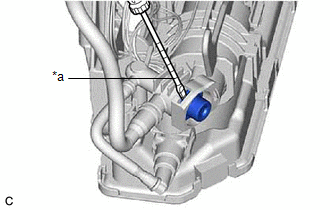

2. REMOVE FUEL MAIN VALVE ASSEMBLY

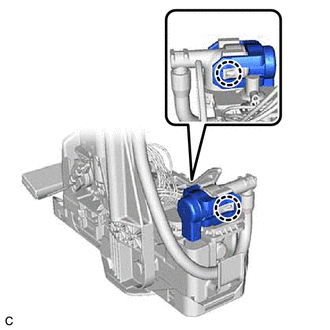

(a) for Type A:

| (1) Remove the clip from the fuel suction tube with pump and gauge assembly. |

|

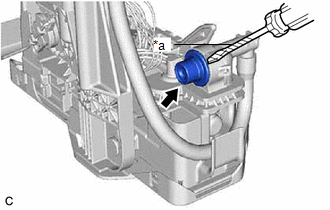

| (2) Using a screwdriver with its tip wrapped with protective tape, remove the fuel main valve assembly from the fuel suction tube with pump and gauge assembly. NOTICE:

|

|

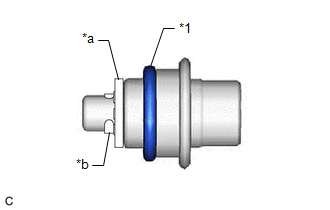

| (3) Remove the 2 O-rings from the fuel main valve assembly. |

|

(b) for Type B:

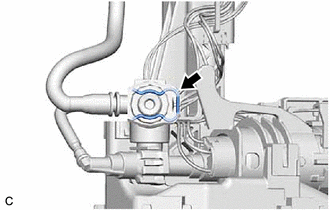

| (1) Disengage the 2 claws and remove the fuel pressure regulator holder from the fuel suction tube with pump and gauge assembly. |

|

| (2) Using a screwdriver with its tip wrapped with protective tape, remove the fuel main valve assembly from the fuel suction tube with pump and gauge assembly. NOTICE:

|

|

| (3) Remove the O-ring from the fuel main valve assembly. NOTICE: Do not remove the mesh and mini-clip from the fuel main valve assembly. |

|

.png)