Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during PCV valve (ventilation valve sub-assembly) removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

| Replaced Part or Performed Procedure | Necessary Procedures | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

-

Replacement of throttle body assembly

-

Cleaning the deposits from the throttle body assembly

-

Replacement of EGR valve assembly

-

Gas leak from exhaust system is repaired

| Inspection After Repair | -

Poor idle, etc.

-

Engine start function, etc.

| .gif) |

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

PROCEDURE

1. REMOVE INTAKE MANIFOLD

Click here .gif)

.gif)

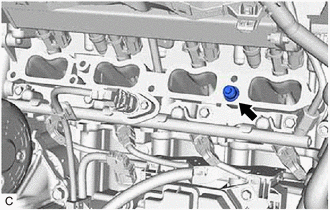

2. REMOVE PCV VALVE (VENTILATION VALVE SUB-ASSEMBLY)

| (a) Remove the PCV valve (ventilation valve sub-assembly) from the cylinder head sub-assembly. | |

READ NEXT:

INSPECTION PROCEDURE 1. INSPECT PCV VALVE (VENTILATION VALVE SUB-ASSEMBLY) (a) Install a hose to the PCV valve (ventilation valve sub-assembly). (b) Check PCV valve (ventilation valve sub-assembly) op

INSTALLATION CAUTION / NOTICE / HINT NOTICE: This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts. Click here

ComponentsCOMPONENTS ILLUSTRATION *1 PURGE VALVE (PURGE VSV) *2 NO. 1 FUEL VAPOR FEED HOSE *3 NO. 2 FUEL VAPOR FEED HOSE - - N*m (kgf*cm, ft.*lbf): Specified torque - -

SEE MORE:

DESCRIPTION The outer mirror switch assembly sends the retractable outer mirror switch signal to the main body ECU (multiplex network body ECU). The main body ECU (multiplex network body ECU) sends the auto retract/return signal to the outer mirror control ECU assemblies via CAN communication, which

DIAGNOSIS SYSTEM DESCRIPTION (a) Power window control system data and Diagnostic Trouble Codes (DTCs) can be read through the vehicle Data Link Connector 3 (DLC3). When the system seems to be malfunctioning, use the Techstream to check for malfunctions and perform repairs. CHECK DLC3 (a) Check the D

© 2016-2026 Copyright www.lexguide.net

.gif)

.gif)

.gif)