Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during direct fuel injector assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

|

*: When performing learning using the Techstream.

Click here | |||

| Battery terminal is disconnected/reconnected | Perform steering sensor zero point calibration | Lane Control System (for Gasoline Model) | |

| Pre-collision System (for Gasoline Model) | |||

| Parking Support Brake System (for Gasoline Model)* | |||

| Lighting System (for Gasoline Model) | |||

| Memorize steering angle neutral point | Parking Assist Monitor System (for Gasoline Model) | | |

| Panoramic View Monitor System (for Gasoline Model) | | ||

| Initialize power trunk lid system | Power Trunk Lid System (for Gasoline Model) | | |

| Inspection after repair |

| |

CAUTION:

-

Never perform work on fuel system components near any possible ignition sources.

.png)

- Vaporized fuel could ignite, resulting in a serious accident.

-

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) battery terminal.

.png)

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

-

To prevent serious injury due to fuel spray from the high-pressure fuel lines, always discharge fuel system pressure before removing any fuel system components.

NOTICE:

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System)

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

PROCEDURE

1. REMOVE FUEL PUMP ASSEMBLY (for High Pressure)

Click here .gif)

2. REMOVE NO. 2 FUEL PIPE SUB-ASSEMBLY

CAUTION:

To prevent serious injury due to fuel spray from the high-pressure fuel lines, always discharge fuel system pressure before removing any fuel system components.

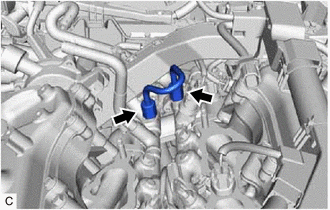

| (a) Using a 17 mm union nut wrench, loosen the 2 union nuts of the No. 2 fuel pipe sub-assembly. |

|

(b) Remove the No. 2 fuel pipe sub-assembly from the fuel delivery pipe with sensor assembly LH and fuel delivery pipe RH.

3. REMOVE WIRE HARNESS CLAMP BRACKET

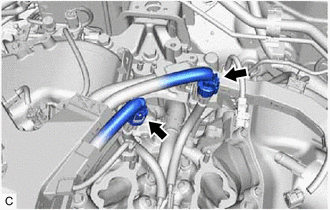

| (a) Disconnect the No. 6 engine wire connector and No. 7 engine wire connector. |

|

| (b) Disengage the 2 clamps to remove the wire harness clamp bracket. |

|

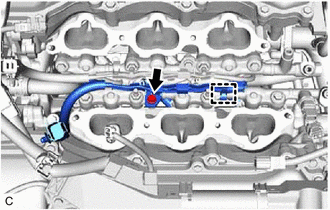

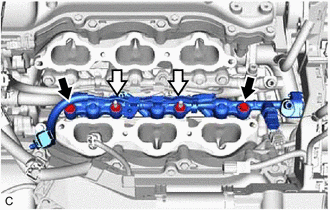

4. REMOVE FUEL DELIVERY PIPE WITH SENSOR ASSEMBLY LH

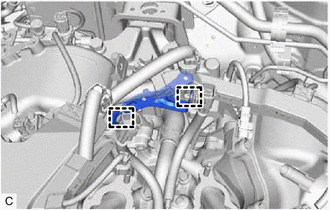

| (a) Disconnect the fuel pressure sensor connector. |

|

| (b) Remove the bolt. |

|

(c) Disengage the clamp to disconnect the No. 7 engine wire from the fuel delivery pipe with sensor assembly LH.

(d) Remove the 2 bolts, 2 nuts and fuel delivery pipe with sensor assembly LH with the 3 direct fuel injector assemblies from the cylinder head LH.

.png) | Bolt |

.png) | Nut |

NOTICE:

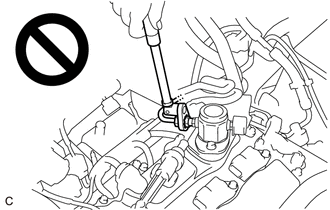

- Make sure not to touch or strike the tips of the direct fuel injector assemblies.

- Pull and remove the fuel delivery pipe with sensor assembly LH in a straight line without tilting it.

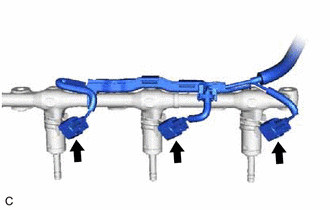

| (e) Disconnect the 3 direct fuel injector assembly connectors. |

|

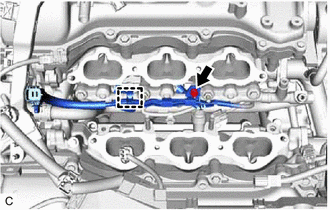

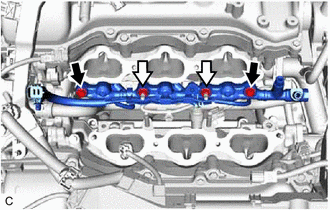

5. REMOVE FUEL DELIVERY PIPE RH

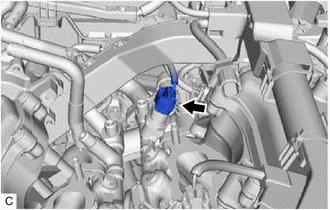

| (a) Remove the bolt. |

|

(b) Disengage the clamp to disconnect the No. 6 engine wire from the fuel delivery pipe RH.

(c) Remove the 2 bolts, 2 nuts and fuel delivery pipe RH with the 3 direct fuel injector assemblies from the cylinder head sub-assembly.

.png) | Bolt |

.png) | Nut |

NOTICE:

- Make sure not to touch or strike the tips of the direct fuel injector assemblies.

- Pull and remove the fuel delivery pipe RH in a straight line without tilting it.

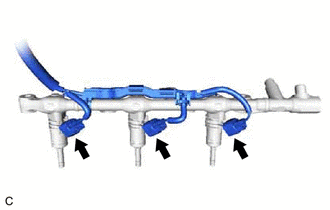

| (d) Disconnect the 3 direct fuel injector assembly connectors. |

|

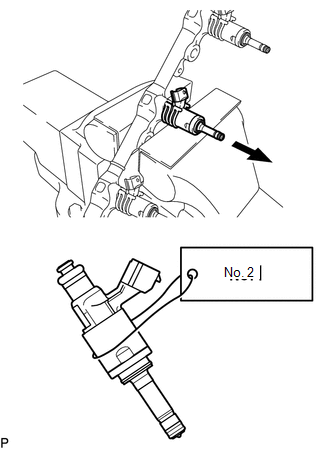

6. REMOVE DIRECT FUEL INJECTOR ASSEMBLY

| (a) Secure the fuel delivery pipe with sensor assembly LH and fuel delivery pipe RH in a vise between aluminum plates and pull out the 6 direct fuel injector assemblies. NOTICE:

|

|

(b) Remove the nozzle holder clamp from each direct fuel injector assembly.

(c) Using needle nose pliers, remove the No. 3 fuel injector back-up ring from each direct fuel injector assembly.

NOTICE:

Do not damage the area that contacts the O-ring.

(d) Remove the O-ring and No. 1 fuel injector back-up ring from each direct fuel injector assembly.

(e) Remove the C-ring and injector vibration insulator from each direct fuel injector assembly.

7. REMOVE FUEL INJECTOR SEAL

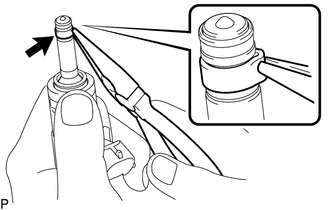

| (a) Using the tip of needle nose pliers, pinch and pull the fuel injector seal at several points to stretch it. NOTICE:

|

|

(b) Remove the fuel injector seal from each direct fuel injector assembly.