Lexus ES: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT STOP LIGHT SWITCH ASSEMBLY

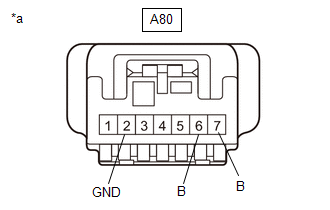

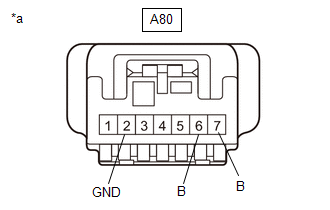

| (a) Disconnect the A80 stop light switch assembly connector. |  | | *a | Front view of wire harness connector (to Stop Light Switch Assembly) | | |

(b) Measure the voltage and resistance on the wire harness side connector according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|

*1: for HV Model

*2: for Gasoline Model |

| A80-7 (B) - A80-2 (GND) | Always | 11 to 14 V |

| A80-6 (B) - A80-2 (GND) | Power switch on (IG)*1 | 11 to 14 V |

| Engine switch on (IG)*2 |

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| A80-2 (GND) - Body ground | Always | Below 1 Ω |

If the result is not as specified, repair or replace the wire harness or connector.

(c) Connect A80 the stop light switch assembly connector.

| (d) Measure the voltage according to the value(s) in the table below. Standard Voltage: | Tester Connection | Condition | Specified Condition | |

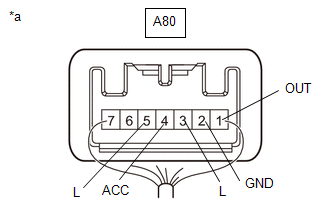

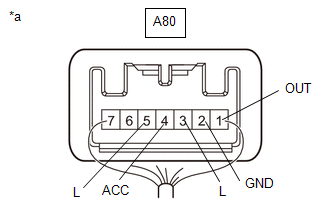

*1: for HV Model

*2: for Gasoline Model | | A80- 1 (OUT) - A80-2 (GND) | Power switch off, brake pedal not depressed*1 | 1.5 V or less | | Engine switch off, brake pedal not depressed*2 | | A80- 1 (OUT) - A80- 2 (GND) | Power switch off, brake pedal depressed*1 | 11 to 14 V | | Engine switch off, brake pedal depressed*2 | | A80-3 (L) - A80-2 (GND) | Power switch off, brake pedal not depressed*1 | 1.5 V or less | | Engine switch off, brake pedal not depressed*2 | | A80-3 (L) - A80-2 (GND) | Power switch off, brake pedal depressed*1 | 11 to 14 V | | Engine switch off, brake pedal depressed*2 | | A80-4 (ACC) - A80-2 (GND) | Always | 11 to 14 V | | A80-5 (L) - A80-2 (GND) | Power switch on (IG), brake pedal not depressed*1 | 7.5 to 14 V | | Engine switch on (IG), brake pedal not depressed*2 | | A80-5 (L) - A80-2 (GND) | Power switch on (IG), brake pedal depressed*1 | 0 to 1.5 V | | Engine switch on (IG), brake pedal depressed*2 | If the result is not as specified, replace the stop light switch assembly. |  | | *a | Component with harness connected (Stop Light Switch Assembly) | | |

READ NEXT:

REMOVAL PROCEDURE 1. REMOVE NO. 1 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY Click here 2. REMOVE STOP LIGHT SWITCH ASSEMBLY (a) Disconnect the connector. (b) Turn the stop light swit

INSTALLATION PROCEDURE 1. INSTALL STOP LIGHT SWITCH ASSEMBLY (a) Insert the stop light switch assembly until the threaded sleeve hits the pedal as shown in the illustration. *1 Stop Light Switch

SEE MORE:

INSPECTION CAUTION / NOTICE / HINT NOTICE:

When using a vise, place aluminum plates between the part and vise.

When using a vise, do not overtighten it.

PROCEDURE 1. INSPECT REAR DRIVE SHAFT ASSEMBLY (a) Check that there is no excessive play in the radial direction of the outboard joint.

INSTALLATION CAUTION / NOTICE / HINT NOTICE:

Avoid any impact to the blind spot monitor sensor.

Do not drop the blind spot monitor sensor. If it is dropped, replace it with a new one.

HINT:

The blind spot monitor beam axis confirmation is performed to confirm whether the sensor beam axis

© 2016-2026 Copyright www.lexguide.net