Lexus ES: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

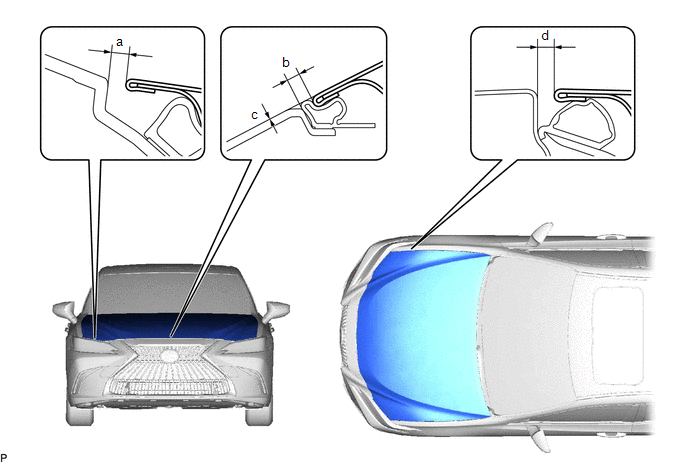

1. INSPECT HOOD SUB-ASSEMBLY

(a) Check that the clearance measurements of areas a through d are within each standard range.

Standard Clearance

Standard Clearance | Area | Measurement | Area | Measurement |

|---|---|---|---|

| a | 2.85 to 5.85 mm (0.112 to 0.230 in.) | b | 1.85 to 5.85 mm (0.0728 to 0.230 in.) |

| c | -1.35 to 1.65 mm (-0.0531 to 0.0650 in.) | d | 2.2 to 5.2 mm (0.0866 to 0.205 in.) |

READ NEXT:

Disassembly

Disassembly

DISASSEMBLY PROCEDURE 1. REMOVE HOOD CUSHION CENTER (a) Using a clip remover, disengage the 10 hood to cowl top seal clips to remove the hood cushion center. (b) Remove the 10 hood to c

Adjustment

Adjustment

ADJUSTMENT CAUTION / NOTICE / HINT *a Centering Bolt *b Standard Bolt HINT:

Centering bolts are used to install the hood hinges and hood lock. The hood and hood lock cannot be adjust

Reassembly

Reassembly

REASSEMBLY PROCEDURE 1. INSTALL HOOD STAY BRACKET LH Click here 2. INSTALL HOOD STAY BRACKET RH HINT: Use the same procedure as for the LH side. 3. INSTALL HOOD SUPPORT ASSEMBLY LH Click here 4. I

SEE MORE:

Vehicle Speed Signal (C1541)

Vehicle Speed Signal (C1541)

DESCRIPTION The power steering ECU (rack and pinion power steering gear assembly) receives vehicle speed signals from the skid control ECU (brake actuator assembly) via CAN communication. The ECU provides appropriate assist force in accordance with the vehicle speed based on the signals. DTC No.

Components

Components

COMPONENTS ILLUSTRATION *A for Side *B for Center *1 COWL SIDE TRIM BOARD *2 FRONT DOOR OPENING TRIM COVER *3 FRONT DOOR SCUFF PLATE *4 FRONT NO. 2 SPEAKER ASSEMBLY *5 FRONT NO. 3 SPEAKER ASSEMBLY *6 FRONT PILLAR GARNISH ASSEMBLY *7 NO. 1 INSTRUMENT PANE

© 2016-2026 Copyright www.lexguide.net