Lexus ES: Lost Communication with Blind Spot Monitor Slave Module (U0232)

DESCRIPTION

This DTC is stored when the blind spot monitor sensor RH judges that there is a communication problem with the blind spot monitor sensor LH.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| U0232 | Lost Communication with Blind Spot Monitor Slave Module | The blind spot monitor sensor (master) cannot receive signals from the blind spot monitor sensor (slave) |

|

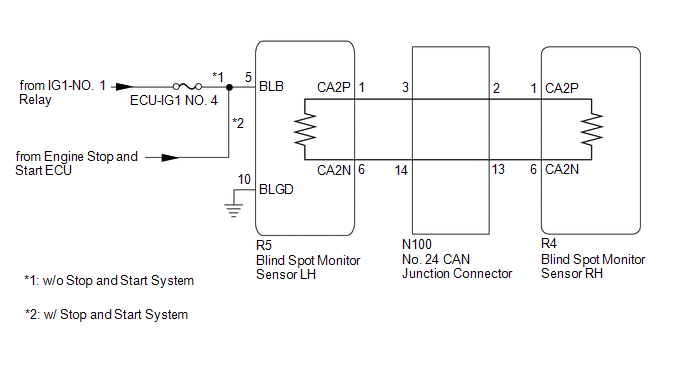

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When checking for DTCs, make sure that the blind spot monitor system is turned on.

- Inspect the fuses for circuits related to this system before performing the following procedure.

- Before measuring the resistance of the CAN bus, turn the engine switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

-

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here

.gif)

.gif)

.gif)

.gif)

HINT:

- Operating the engine switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

- Even after DTCs are cleared, if a DTC is stored again after driving the vehicle for a while, the malfunction may be occurring due to vibration of the vehicle. In such a case, wiggling the ECUs or wire harness while performing the inspection below may help determine the cause of the malfunction.

PROCEDURE

| 1. | CONFIRM MODEL |

(a) Choose the model to be inspected.

| Result | Proceed to |

|---|---|

| w/ Parking Support Brake System | A |

| w/o Parking Support Brake System | B |

| B |  | GO TO STEP 3 |

|

| 2. | CHECK DTC OUTPUT (PARKING SUPPORT BRAKE SYSTEM) |

(a) Using the Techstream, check for DTCs according to the prompts on the screen.

Click here .gif)

Standard:

The clearance warning ECU assembly does not output DTCs U0232 and U0233 simultaneously.

| NG |  | GO TO PARKING SUPPORT BRAKE SYSTEM (DTC U0232) |

|

| 3. | CHECK CAN BUS MAIN WIRE |

(a) Turn the engine switch off.

(b) Disconnect the cable from the negative (-) battery terminal.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| Result | Proceed to |

|---|---|

| OK | A |

| Open circuit in CAN main bus lines | B |

| Short circuit between bus lines | C |

| D |

| B |  | GO TO STEP 9 |

| C |  | GO TO STEP 12 |

| D |  | GO TO STEP 15 |

|

| 4. | CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH - BODY GROUND) |

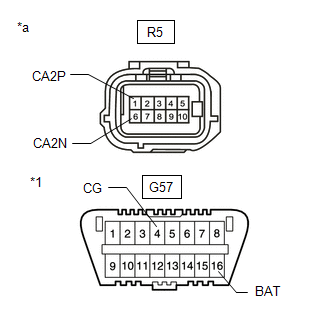

(a) Disconnect the R5 blind spot monitor sensor LH connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R5-10 (BLGD) - Body ground | Always | Below 1 Ω |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. | CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH POWER SOURCE) |

(a) Disconnect the R5 blind spot monitor sensor LH connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R5-5 (BLB) - Body ground | Engine switch on (IG) | 11 to 14 V |

| R5-5 (BLB) - Body ground | Engine switch off | Below 1 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 6. | CHECK DTC |

(a) Reconnect the cable to the negative (-) battery terminal.

(b) Turn the engine switch off.

(c) Turn the engine switch on (IG).

(d) Check for DTCs.

Click here .gif)

OK:

No DTCs are output.

| OK |  | USE SIMULATION METHOD TO CHECK |

|

| 7. | REPLACE BLIND SPOT MONITOR SENSOR LH |

(a) Replace the blind spot monitor sensor LH.

Click here .gif)

.gif)

|

| 8. | RECHECK DTC |

(a) Clear the DTCs.

Click here .gif)

(b) Recheck for DTCs and check if the same DTC is output again.

Body Electrical > Blind Spot Monitor Master > Trouble CodesOK:

No DTCs are output.

| OK |  | END |

| NG |  | REPLACE BLIND SPOT MONITOR SENSOR RH |

| 9. | CHECK FOR OPEN IN CAN BUS MAIN WIRE (NO. 24 CAN JUNCTION CONNECTOR) |

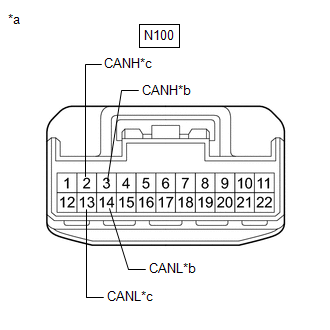

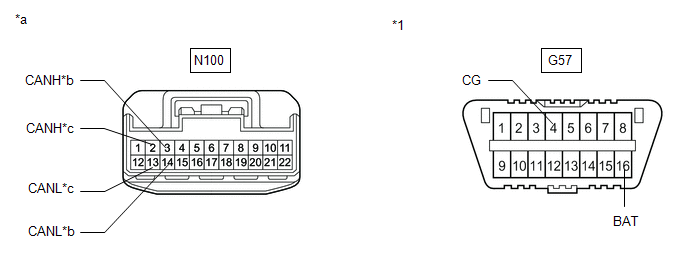

| (a) Disconnect the N100 No. 24 CAN junction connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N100-3 (CANH) - N100-14 (CANL) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| N100-2 (CANH) - N100-13 (CANL) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| Result | Proceed to |

|---|---|

| OK | A |

| NG (to blind spot monitor sensor LH CAN main wire) | B |

| NG (to blind spot monitor sensor RH CAN main wire) | C |

| A |  | REPLACE NO. 24 CAN JUNCTION CONNECTOR |

| C |  | GO TO STEP 11 |

|

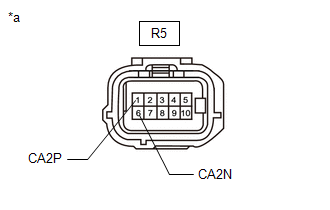

| 10. | CHECK FOR OPEN IN CAN BUS MAIN WIRE (BLIND SPOT MONITOR SENSOR LH) |

(a) Reconnect the N100 No. 24 CAN junction connector.

| (b) Disconnect the R5 blind spot monitor sensor LH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R5-1 (CA2P) - R5-6 (CA2N) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| OK |  | REPLACE BLIND SPOT MONITOR SENSOR LH |

| NG |  | REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - NO. 24 CAN JUNCTION CONNECTOR) |

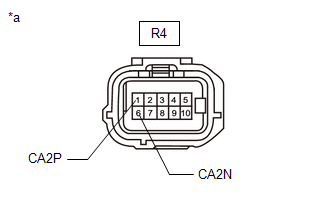

| 11. | CHECK FOR OPEN IN CAN BUS MAIN WIRE (BLIND SPOT MONITOR SENSOR RH) |

(a) Reconnect the N100 No. 24 CAN junction connector.

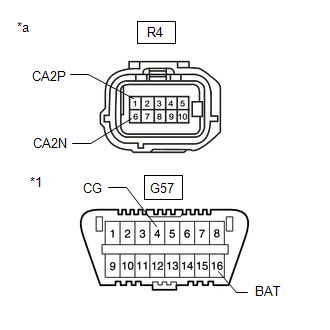

| (b) Disconnect the R4 blind spot monitor sensor RH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R4-1 (CA2P) -R4-6 (CA2N) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| OK |  | REPLACE BLIND SPOT MONITOR SENSOR RH |

| NG |  | REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH - NO. 24 CAN JUNCTION CONNECTOR) |

| 12. | CHECK FOR SHORT IN CAN BUS WIRES (NO. 24 CAN JUNCTION CONNECTOR) |

| (a) Disconnect the N100 No. 24 CAN junction connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N100-3 (CANH) - N100-14 (CANL) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| N100-2 (CANH) - N100-13 (CANL) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| Result | Proceed to |

|---|---|

| OK | A |

| NG (to blind spot monitor sensor LH CAN main wire) | B |

| NG (to blind spot monitor sensor RH CAN main wire) | C |

| A |  | REPLACE NO. 24 CAN JUNCTION CONNECTOR |

| C |  | GO TO STEP 14 |

|

| 13. | CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR LH) |

(a) Reconnect the N100 No. 24 CAN junction connector.

| (b) Disconnect the R5 blind spot monitor sensor LH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R5-1 (CA2P) - R5-6 (CA2N) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| OK |  | REPLACE BLIND SPOT MONITOR SENSOR LH |

| NG |  | REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - NO. 24 CAN JUNCTION CONNECTOR) |

| 14. | CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR RH) |

(a) Reconnect the N100 No. 24 CAN junction connector.

| (b) Disconnect the R4 blind spot monitor sensor RH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R4-1 (CA2P) -R4-6 (CA2N) | Cable disconnected from negative (-) battery terminal | 108 to 132 Ω |

| OK |  | REPLACE BLIND SPOT MONITOR SENSOR RH |

| NG |  | REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH - NO. 24 CAN JUNCTION CONNECTOR) |

| 15. | CHECK FOR SHORT IN CAN BUS WIRES (NO. 24 CAN JUNCTION CONNECTOR) |

(a) Disconnect the N100 No. 24 CAN junction connector.

(b) Measure the resistance according to the value(s) in the table below.

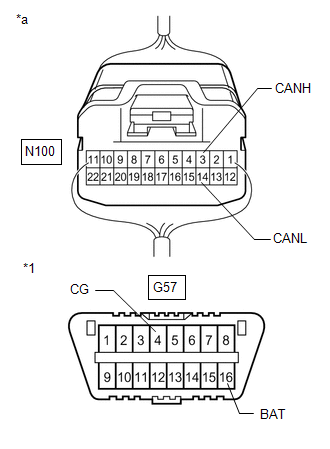

| *1 | DLC3 | - | - |

| *a | Front view of wire harness connector (to No. 24 CAN Junction Connector) | *b | to Blind Spot Monitor Sensor LH CAN main wire |

| *c | to Blind Spot Monitor Sensor RH CAN main wire | - | - |

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N100-3 (CANH) - G57-4 (CG) | Cable disconnected from negative (-) battery terminal | 200 Ω or higher |

| N100-14 (CANL) - G57-4 (CG) | Cable disconnected from negative (-) battery terminal | 200 Ω or higher |

| N100-3 (CANH) - G57-16 (BAT) | Cable disconnected from negative (-) battery terminal | 6 kΩ or higher |

| N100-14 (CANL) - G57-16 (BAT) | Cable disconnected from negative (-) battery terminal | 6 kΩ or higher |

| N100-2 (CANH) - G57-4 (CG) | Cable disconnected from negative (-) battery terminal | 200 Ω or higher |

| N100-13 (CANL) - G57-4 (CG) | Cable disconnected from negative (-) battery terminal | 200 Ω or higher |

| N100-2 (CANH) - G57-16 (BAT) | Cable disconnected from negative (-) battery terminal | 6 kΩ or higher |

| N100-13 (CANL) - G57-16 (BAT) | Cable disconnected from negative (-) battery terminal | 6 kΩ or higher |

| Result | Proceed to |

|---|---|

| OK | A |

| NG (to blind spot monitor sensor LH CAN main wire) | B |

| NG (to blind spot monitor sensor RH CAN main wire) | C |

| A |  | REPLACE NO. 24 CAN JUNCTION CONNECTOR |

| C |  | GO TO STEP 17 |

|

| 16. | CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR LH) |

(a) Reconnect the N100 No. 24 CAN junction connector.

(b) Disconnect the R5 blind spot monitor sensor LH connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK |  | REPLACE BLIND SPOT MONITOR SENSOR LH |

| NG |  | REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - NO. 24 CAN JUNCTION CONNECTOR) |

| 17. | CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR RH) |

(a) Reconnect the N100 No. 24 CAN junction connector.

(b) Disconnect the R4 blind spot monitor sensor RH connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK |  | REPLACE BLIND SPOT MONITOR SENSOR RH |

| NG |  | REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH - NO. 24 CAN JUNCTION CONNECTOR) |