Lexus ES: Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst)

(a) Install a new gasket to the front exhaust pipe assembly (TWC: Rear Catalyst).

(b) Connect the front exhaust pipe assembly (TWC: Rear Catalyst) to the 2 exhaust pipe supports.

(c) Install the front exhaust pipe assembly (TWC: Rear Catalyst) to the exhaust manifold (TWC: Front Catalyst) with 2 new nuts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

2. INSTALL AIR FUEL RATIO SENSOR (for Sensor 2)

Click here .gif)

3. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the front exhaust pipe assembly (TWC: Rear Catalyst).

(b) Connect the center exhaust pipe assembly to the exhaust pipe support.

(c) Install the center exhaust pipe assembly to the front exhaust pipe assembly (TWC: Rear Catalyst) with 2 new bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

4. INSTALL TAIL EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe assembly.

(b) Connect the tail exhaust pipe assembly to the 2 exhaust pipe supports.

(c) Install the tail exhaust pipe assembly to the center exhaust pipe assembly with 2 new bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

5. INSTALL CENTER FLOOR CROSSMEMBER BRACE

(a) Install the center floor crossmember brace to the vehicle body with the 4 bolts.

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

6. INSTALL FRONT CENTER FLOOR BRACE

(a) Install the front center floor brace to the vehicle body with the 4 bolts.

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

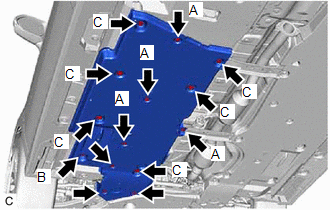

7. INSTALL FRONT FLOOR COVER LH

| (a) Install the front floor cover LH with the grommet (B) and 6 clips (C). |

|

(b) Install the 3 bolts and 4 clips (A).

Torque:

Bolt :

7.5 N·m {76 kgf·cm, 66 in·lbf}

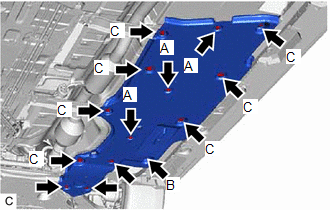

8. INSTALL FRONT FLOOR COVER RH

| (a) Install the front floor cover RH with the grommet (B) and 7 clips (C). |

|

(b) Install the 3 bolts and 3 clips (A).

Torque:

Bolt :

7.5 N·m {76 kgf·cm, 66 in·lbf}

9. INSPECT FOR EXHAUST GAS LEAK

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

(a) Perform "Inspection After Repair" after repairing an exhaust gas leak.

Click here .gif)