Lexus ES: Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

(a) Type A

(1) Install the No. 2 exhaust manifold heat insulator to the exhaust manifold (TWC: Front Catalyst) with the 6 bolts.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

(b) Type B

(1) Install the No. 2 exhaust manifold heat insulator to the exhaust manifold (TWC: Front Catalyst) with the 3 bolts.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

2. INSTALL EXHAUST MANIFOLD (TWC: Front Catalyst)

(a) Install a new exhaust manifold to head gasket to the cylinder head sub-assembly.

(b) Temporarily install the exhaust manifold (TWC: Front Catalyst), No. 1 upper front floor heat insulator and No. 1 exhaust manifold heat insulator.

HINT:

At this time, do not install the parts with bolts or nuts.

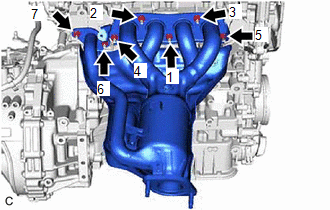

| (c) Temporarily install the exhaust manifold (TWC: Front Catalyst) to the cylinder head sub-assembly with 7 new nuts. |

|

(d) Using a 12 mm deep socket wrench, tighten the 7 nuts in the order shown in the illustration.

Torque:

26 N·m {265 kgf·cm, 19 ft·lbf}

3. INSTALL MANIFOLD STAY

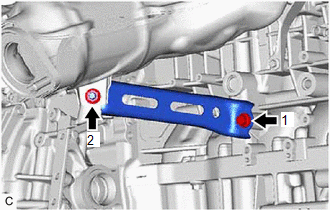

| (a) Temporarily install the manifold stay to the exhaust manifold (TWC: Front Catalyst) and cylinder block sub-assembly with the bolt and nut. |

|

(b) Tighten the bolt and nut in the order shown in the illustration.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

4. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

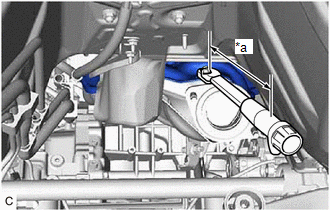

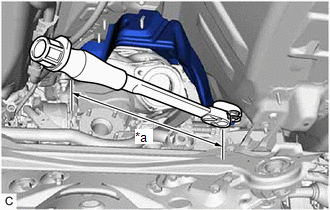

| (a) Type A (1) Using a 10 mm union nut wrench, install the No. 1 exhaust manifold heat insulator to the exhaust manifold (TWC: Front Catalyst) with the 5 bolts. Torque: Specified tightening torque : 10 N·m {102 kgf·cm, 7 ft·lbf} HINT:

|

|

(b) Type B

(1) Install the No. 1 exhaust manifold heat insulator to the exhaust manifold (TWC: Front Catalyst) with the 3 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

5. INSTALL NO. 1 UPPER FRONT FLOOR HEAT INSULATOR

| (a) Using a 10 mm union nut wrench, install the No. 1 upper front floor heat insulator to the vehicle body with the 3 nuts. Torque: Specified tightening torque : 4.9 N·m {50 kgf·cm, 43 in·lbf} HINT:

|

|

6. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the wire harness clamp bracket with the bolt.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

7. INSTALL AIR FUEL RATIO SENSOR (for Sensor 1)

Click here .gif)

8. INSTALL FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY

Click here .gif)

.gif)

9. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

Click here .gif)

10. INSTALL FRONT LOWER NO. 1 FLOOR HEAT INSULATOR

Click here .gif)

11. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

Click here .gif)

12. INSTALL FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst)

(a) Install 2 new gaskets to the front exhaust pipe assembly (TWC: Rear Catalyst).

(b) Connect the front exhaust pipe assembly (TWC: Rear Catalyst) to the 2 exhaust pipe supports.

(c) Install the front exhaust pipe assembly (TWC: Rear Catalyst) to the exhaust manifold (TWC: Front Catalyst) and center exhaust pipe assembly with 2 new bolts and 2 new nuts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

(d) Connect the air fuel ratio sensor (for sensor 2) connector.

(e) Engage the 2 wire harness clamps.

13. INSTALL CENTER FLOOR CROSSMEMBER BRACE

Click here .gif)

14. INSTALL FRONT CENTER FLOOR BRACE

Click here .gif)

15. INSTALL FRONT FLOOR COVER LH

Click here .gif)

16. INSTALL FRONT FLOOR COVER RH

Click here .gif)

17. INSPECT FOR EXHAUST GAS LEAK

Click here .gif)

18. INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY

Click here .gif)

.gif)

19. INSTALL NO. 1 ENGINE UNDER COVER

Click here .gif)

.gif)

20. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

Click here .gif)

.gif)

21. INSTALL FRONT WHEEL OPENING EXTENSION PAD RH

Click here .gif)

.gif)