Lexus ES: Installation

INSTALLATION

PROCEDURE

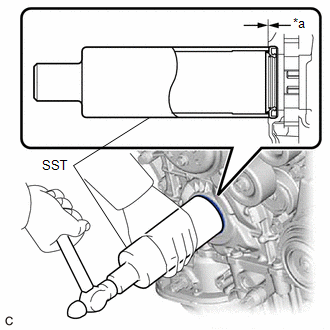

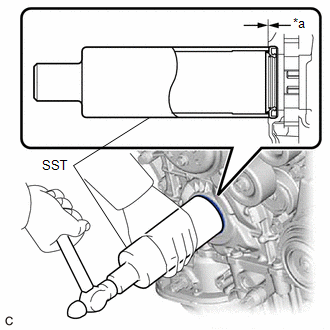

1. INSTALL TIMING CHAIN CASE OIL SEAL

| (a) Apply MP grease to the lip of a new timing chain case oil seal. |  | | *a | Oil Seal Protrusion Height | | |

(b) Using SST and a hammer, tap in the timing chain case oil seal until its surface is flush with the timing chain cover assembly edge.

SST: 09316-60012

09316-00011

Oil Seal Protrusion Height:

0 to 1.0 mm (0 to 0.0394 in.)

NOTICE:

-

Keep the lip free from foreign matter.

-

Do not tap in the timing chain case oil seal at an angle.

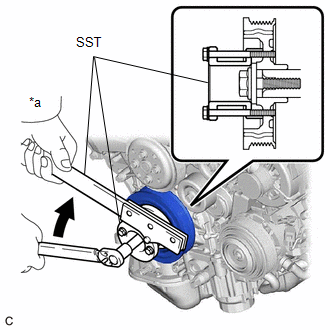

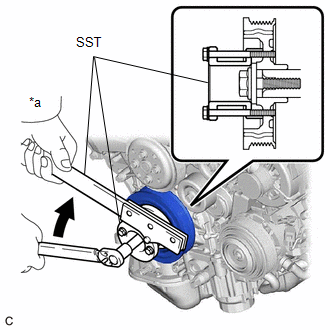

2. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the crankshaft pulley.

(b) Using SST to hold the crankshaft pulley in place, tighten the crankshaft pulley set bolt.

| *a | Hold |

.png) | Turn |

SST: 09213-70011

09213-70020

SST: 09330-00021

Torque:

260 N·m {2651 kgf·cm, 192 ft·lbf}

3. INSTALL V-RIBBED BELT

Click here .gif)

4. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

Click here .gif)

READ NEXT:

COMPONENTS ILLUSTRATION *1 REAR ENGINE OIL SEAL *2 NO. 1 CRANKSHAFT POSITION SENSOR PLATE *3 DRIVE PLATE AND RING GEAR SUB-ASSEMBLY *4 REAR DRIVE PLATE SPACER N*m (kgf*cm, f

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during rear

SEE MORE:

INSPECTION PROCEDURE 1. INSPECT FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY) (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 22 to 28 Ω If the result is not as s

PROBLEM SYMPTOMS TABLE HINT:

Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the suspect

© 2016-2026 Copyright www.lexguide.net

.png)

.gif)

.gif)