Lexus ES: Installation

INSTALLATION

PROCEDURE

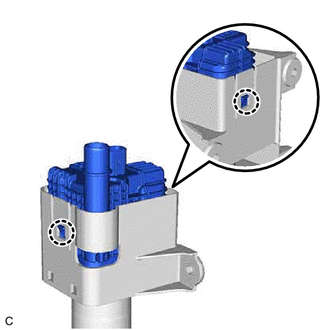

1. INSTALL LEAK DETECTION PUMP SUB-ASSEMBLY

HINT:

Only perform this procedure when replacement of the leak detection pump sub-assembly is necessary.

| (a) Engage the 2 claws to install a new leak detection pump sub-assembly to the No. 2 charcoal canister sub-assembly. NOTICE:

|

|

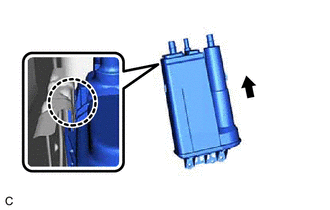

2. INSTALL NO. 2 CHARCOAL CANISTER SUB-ASSEMBLY

(a) Install the No. 2 charcoal canister sub-assembly to the vehicle body with the 3 nuts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(b) Connect the leak detection pump sub-assembly connector.

(c) Push in the air line tube to the pipe (leak detection pump sub-assembly) until the air line tube makes a "click" sound.

NOTICE:

- Check that there are no scratches or foreign matter around the connecting parts of the tube connector and pipe (leak detection pump sub-assembly) before performing this work.

- After connecting the air line tube, check that the air line tube is securely connected by pulling on the tube connector.

3. INSTALL CANISTER (CHARCOAL CANISTER ASSEMBLY)

(a) Install the clip to the vehicle body.

| (b) Engage the claw to install the canister (charcoal canister assembly) to the vehicle body as shown in the illustration. |

|

(c) Engage the clip to the canister (charcoal canister assembly).

(d) Install the 2 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(e) Connect the purge line hose to the canister (charcoal canister assembly) and slide the clip to secure it.

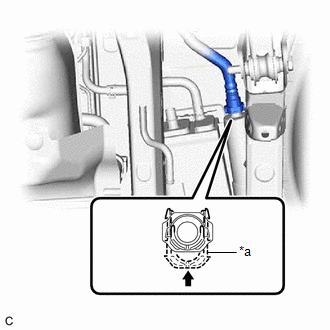

(f) Push the vent line hose onto the canister (charcoal canister assembly) and push in the retainer to engage the lock claws.

NOTICE:

- Check that there are no scratches or foreign matter around the connecting parts of the tube connector and pipe (canister (charcoal canister assembly)) before performing this work.

- After connecting the vent line hose, check that the vent line hose is securely connected by pulling on the tube connector.

| *a | Retainer |

.png) | Push in |

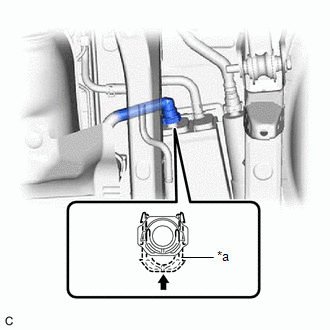

(g) Push the fuel tank vent hose onto the canister (charcoal canister assembly) and push in the retainer to engage the lock claws.

NOTICE:

- Check that there are no scratches or foreign matter around the connecting parts of the tube connector and pipe (canister (charcoal canister assembly)) before performing this work.

- After connecting the fuel tank vent hose, check that the fuel tank vent hose is securely connected by pulling on the tube connector.

| *a | Retainer |

.png) | Push in |

4. INSTALL REAR NO. 1 STABILIZER BAR BRACKET

(a) Install the 2 rear No. 1 stabilizer bar brackets to the vehicle body with the 4 bolts.

Torque:

78 N·m {795 kgf·cm, 58 ft·lbf}

5. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Install 3 new gaskets to the front exhaust pipe assembly (TWC: Rear Catalyst) and center exhaust pipe assembly.

(b) Connect the center exhaust pipe assembly to the 2 exhaust pipe supports.

(c) Install the center exhaust pipe assembly to the front exhaust pipe assembly (TWC: Rear Catalyst), tail exhaust pipe assembly and tail exhaust pipe assembly LH with 6 new bolts and 2 new nuts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

6. INSTALL CENTER FLOOR CROSSMEMBER BRACE

Click here .gif)

7. INSTALL FRONT CENTER FLOOR BRACE

Click here .gif)

8. INSTALL FRONT FLOOR COVER LH

Click here .gif)

9. INSTALL FRONT FLOOR COVER RH

Click here .gif)

10. INSPECT FOR EXHAUST GAS LEAK

Click here .gif)