Lexus ES: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. INSTALL FRONT DRIVE SHAFT HOLE SNAP RING

(a) Install a new front drive shaft hole snap ring.

NOTICE:

Face the end gap of the front drive shaft hole snap ring downward.

2. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

(a) Coat the snap ring of the front drive inboard joint assembly with MP grease.

(b) Coat the splines of the front drive inboard joint assembly with Toyota genuine ATF WS.

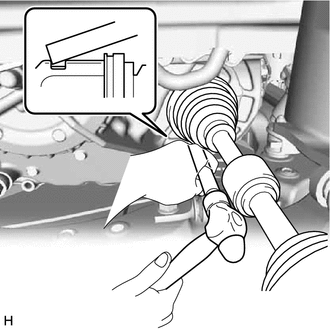

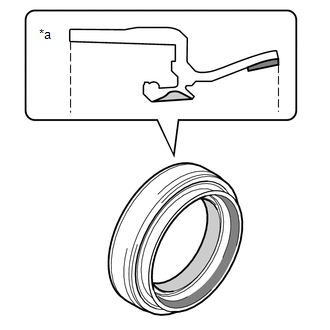

(c) Coat the lip of the front drive shaft oil seal LH with MP grease and Toyota genuine oil seal side lip grease as shown in the illustration.

| *a | Cross Section of Front Drive Shaft Oil Seal LH |

| MP Grease |

| Toyota Genuine Oil Seal Side Lip Grease |

HINT:

Apply a light coat of MP grease and Toyota genuine oil seal side lip grease to the entire circumference of the front drive shaft oil seal LH.

| (d) Align the inboard joint splines, and using a brass bar and a hammer, install the front drive shaft assembly LH. NOTICE:

HINT: Confirm whether the drive shaft is securely driven in by checking the reaction force and sound. |

|

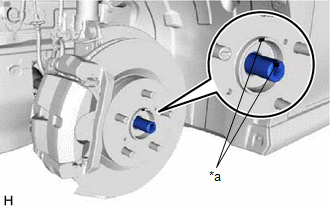

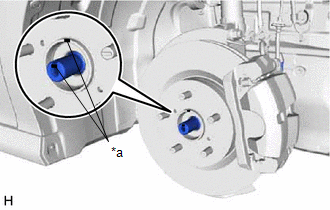

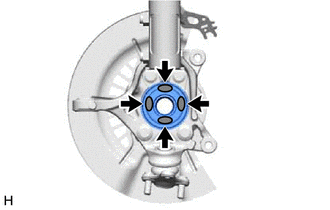

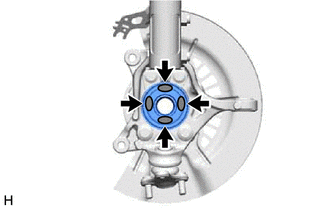

(e) Apply 0.1 to 0.3 g (0.00353 to 0.0105 oz) of Toyota Body Grease W to each of the 4 areas shown in the illustration.

.png) | Toyota Body Grease W |

| (f) Align the matchmarks and install the front drive shaft assembly LH to the front axle assembly. NOTICE:

|

|

3. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

(a) Coat the splines of the front drive inboard joint assembly with Toyota genuine ATF WS.

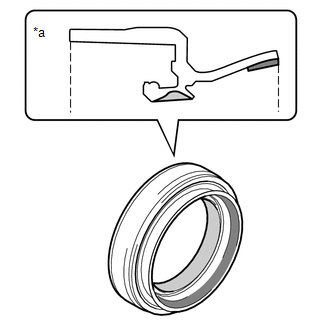

(b) Coat the lip of the front drive shaft oil seal RH with MP grease and Toyota genuine oil seal side lip grease as shown in the illustration.

HINT:

Apply a light coat of Toyota genuine oil seal side lip grease to the entire circumference of the front drive shaft oil seal RH.

| *a | Cross Section of Front Drive Shaft Oil Seal RH |

| MP Grease |

| Toyota Genuine Oil Seal Side Lip Grease |

(c) Align the inboard joint splines, and securely insert the front drive shaft assembly RH.

NOTICE:

- Do not damage the front drive shaft oil seal RH.

- Do not damage the front axle inboard joint boot.

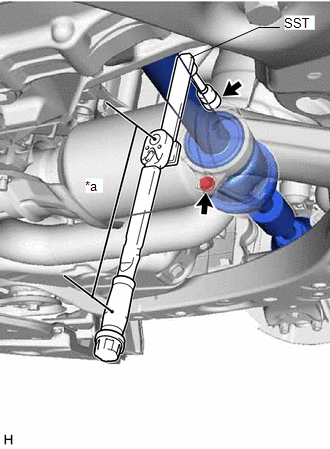

| (d) Install the front drive shaft assembly RH with the 2 bolts. SST: 09961-00950 Torque: Specified tightening torque : 50.5 N·m {515 kgf·cm, 37 ft·lbf} HINT:

|

|

(e) Apply 0.1 to 0.3 g (0.00353 to 0.0105 oz) of Toyota Body Grease W to each of the 4 areas shown in the illustration.

.png) | Toyota Body Grease W |

| (f) Align the matchmarks and install the front drive shaft assembly RH to the front axle assembly. NOTICE:

|

|

4. CONNECT FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY

Click here .gif)

5. INSTALL FRONT STABILIZER LINK ASSEMBLY

Click here .gif)

.gif)

6. CONNECT TIE ROD ASSEMBLY

Click here .gif)

.gif)

7. INSTALL FRONT SPEED SENSOR (w/o AVS)

Click here .gif)

8. INSTALL FRONT SPEED SENSOR (w/ AVS)

Click here .gif)

9. INSTALL FRONT AXLE SHAFT NUT

(a) Clean the threaded parts on the front drive shaft assembly and a new front axle shaft nut using non-residue solvent.

NOTICE:

- Make sure to perform this work even when using a new front drive shaft assembly.

- Keep the threaded parts free of oil and foreign matter.

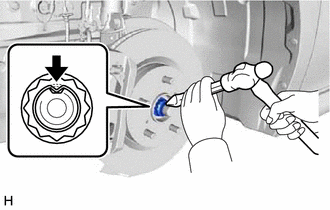

| (b) Using a 30 mm deep socket wrench, install the front axle shaft nut. Torque: 294 N·m {2998 kgf·cm, 217 ft·lbf} HINT: Depress the brake pedal to prevent the drive shaft from rotating. |

|

(c) Using a chisel and hammer, stake the front axle shaft nut.

10. ADD AUTOMATIC TRANSAXLE FLUID

Click here .gif)

.gif)

11. INSTALL FRONT WHEELS

Click here .gif)

12. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

Click here .gif)

.gif)

.gif)

13. INSTALL FRONT FENDER APRON SEAL LH

Click here .gif)

14. INSTALL FRONT FENDER APRON SEAL RH

Click here .gif)

15. INSTALL NO. 2 ENGINE UNDER COVER

Click here .gif)

16. INSTALL NO. 3 ENGINE UNDER COVER

Click here .gif)

17. INSTALL NO. 1 ENGINE UNDER COVER

Click here .gif)

18. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

Click here .gif)

19. INSTALL FRONT WHEEL OPENING EXTENSION PAD RH

Click here .gif)

20. CHECK FOR SPEED SENSOR SIGNAL

Click here .gif)

.gif)