Lexus ES: Inspection

INSPECTION

CAUTION / NOTICE / HINT

NOTICE:

- When using a vise, place aluminum plates between the part and vise.

- When using a vise, do not overtighten it.

PROCEDURE

1. INSPECT REAR DRIVE SHAFT ASSEMBLY

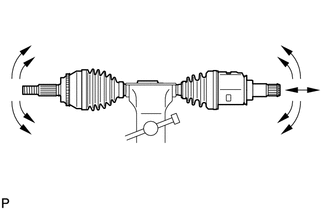

| (a) Check that there is no excessive play in the radial direction of the outboard joint. |

|

(b) Check that the inboard joint slides smoothly in the thrust direction.

(c) Check that there is no excessive play in the radial direction of the inboard joint.

(d) Check the boots for damage.

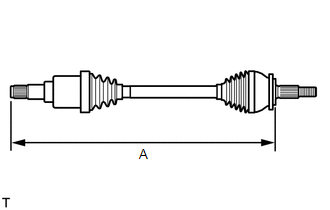

| (e) Check whether the drive shaft dimension (A) is within specification. Length (A): 749.1 to 759.1 mm (2.46 to 2.49 ft.) NOTICE: Keep the drive shaft assembly level during inspection. If the boots are stretched or contracted, correct them. |

|

READ NEXT:

Installation

Installation

INSTALLATION CAUTION / NOTICE / HINT HINT:

Use the same procedure for the RH and LH sides.

The procedure listed below is for the LH side.

PROCEDURE 1. INSTALL REAR DRIVE SHAFT INBOARD JOINT SH

Reassembly

Reassembly

REASSEMBLY CAUTION / NOTICE / HINT NOTICE:

When using a vise, place aluminum plates between the part and vise.

When using a vise, do not overtighten it.

HINT:

Use the same procedure for the

Removal

Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rea

SEE MORE:

Blind Spot Monitor Beam Axis Misalignment (C1AFA)

Blind Spot Monitor Beam Axis Misalignment (C1AFA)

DESCRIPTION This DTC is stored when the clearance warning ECU assembly receives a signal from the blind spot monitor system via CAN communication indicating blind spot monitor beam axis misalignment. DTC No. Detection Item DTC Detection Condition Trouble Area C1AFA Blind Spot Monitor

Disassembly

Disassembly

DISASSEMBLY CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during cylinder head removal/installation are shown below. Necessary Procedure After Parts Removed/Install

© 2016-2026 Copyright www.lexguide.net