Lexus ES: Driver Side Camera Video Sync Signal Malfunction (C1686)

DESCRIPTION

This DTC is stored if the parking assist ECU judges as a result of its self check that a synchronization problem is occurring in the image signal sent from the driver side television camera assembly to the parking assist ECU.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| C1686 | Driver Side Camera Video Sync Signal Malfunction | Side camera feedback malfunction |

|

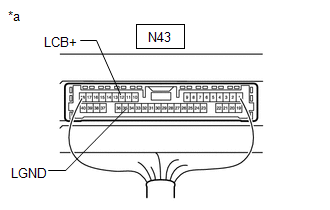

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When "!" is displayed on the multi-display assembly after the cable is disconnected from the negative (-) auxiliary battery terminal, correct the steering angle neutral point.

-

Depending on the parts that are replaced or operations that are performed during vehicle inspection or maintenance, calibration of other systems as well as the panoramic view monitor system may be needed.

Click here

.gif)

PROCEDURE

| 1. | CHECK FOR DTC |

(a) Clear the DTCs.

Chassis > Circumference Monitoring Camera Control Module > Clear DTCs(b) Check for DTCs.

Chassis > Circumference Monitoring Camera Control Module > Trouble CodesOK:

DTC C1686 is not output.

| OK |  | USE SIMULATION METHOD TO CHECK |

|

| 2. | CHECK HARNESS AND CONNECTOR (PARKING ASSIST ECU - OUTER REAR VIEW MIRROR ASSEMBLY LH) |

(a) Disconnect the N43 parking assist ECU connector.

(b) Disconnect the J34 outer rear view mirror assembly LH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N43-12 (LCB+) - J34-2 (LCB+) | Always | Below 1 Ω |

| N43-10 (LCV+) - J34-7 (LCV+) | Always | Below 1 Ω |

| N43-34 (LCV-) - J34-6 (LCV-) | Always | Below 1 Ω |

| N43-35 (LGND) - J34-1 (LGND) | Always | Below 1 Ω |

| N43-11 (SGND) - J34-3 (SGND) | Always | Below 1 Ω |

| N43-12 (LCB+) or J34-2 (LCB+) - Body ground | Always | 10 kΩ or higher |

| N43-10 (LCV+) or J34-7 (LCV+) - Body ground | Always | 10 kΩ or higher |

| N43-34 (LCV-) or J34-6 (LCV-) - Body ground | Always | 10 kΩ or higher |

| N43-35 (LGND) or J34-1 (LGND) - Body ground | Always | 10 kΩ or higher |

| N43-11 (SGND) or J34-3 (SGND) - Body ground | Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

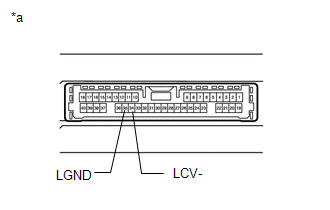

| 3. | CHECK PARKING ASSIST ECU (LCV-, LGND) |

(a) Disconnect the N43 parking assist ECU connector.

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |  | REPLACE PARKING ASSIST ECU |

|

| 4. | CHECK PARKING ASSIST ECU (LCB+, LGND) |

| (a) Remove the parking assist ECU with the connector still connected. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N43-35 (LGND) - Body ground | Always | Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N43-12 (LCB+) - N43-35 (LGND) | Power switch on (IG) | 5.5 to 7.05 V |

| NG |  | REPLACE PARKING ASSIST ECU |

|

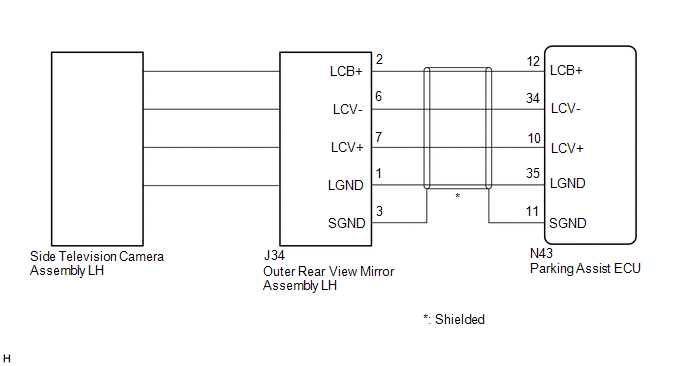

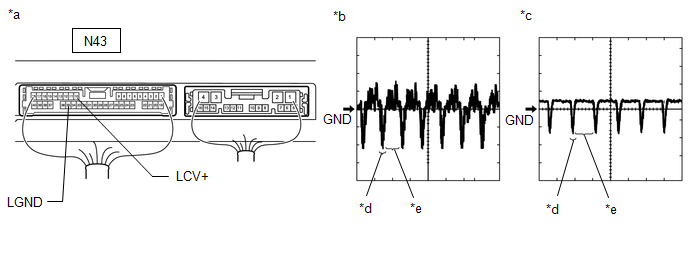

| 5. | CHECK SIDE TELEVISION CAMERA ASSEMBLY LH (LCV+, LGND) |

(a) Remove the parking assist ECU with the connector still connected.

(b) Using an oscilloscope, check the waveform of the side television camera assembly LH.

HINT:

A waterproof connector is used for the side television camera assembly LH. Therefore, inspect the waveform at the parking assist ECU with the connector connected.

| *a | Component with harness connected (Parking Assist ECU) | *b | Waveform 1 (camera lens not covered, displaying an image) |

| *c | Waveform 2 (camera lens covered, blacking out the screen) | *d | Synchronization Signal |

| *e | Video Waveform | - | - |

HINT:

- The video waveform changes according to the image sent by the side television camera assembly LH.

- The video waveform is constantly output when the power switch is on (ACC).

| Item | Content |

|---|---|

| Tester Connection | N43-10 (LCV+) - N43-35 (LGND) |

| Tool Setting | 200 mV/DIV., 50 μsec./DIV. |

| Condition | Power switch on (IG), panoramic view monitor system operating |

OK:

Waveform is similar to that shown in illustration.

| OK |  | REPLACE PARKING ASSIST ECU |

|

| 6. | CHECK SIDE TELEVISION CAMERA ASSEMBLY LH |

(a) Replace the side television camera assembly LH with a new or normally functioning one.

Click here .gif)

|

| 7. | CHECK FOR DTC |

(a) Clear the DTCs.

Chassis > Circumference Monitoring Camera Control Module > Clear DTCs(b) Check for DTCs.

Chassis > Circumference Monitoring Camera Control Module > Trouble CodesOK:

DTC C1686 is not output.

| OK |  | END (SIDE TELEVISION CAMERA ASSEMBLY LH IS DEFECTIVE) |

| NG |  | REPLACE OUTER REAR VIEW MIRROR ASSEMBLY LH |