Lexus ES: Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

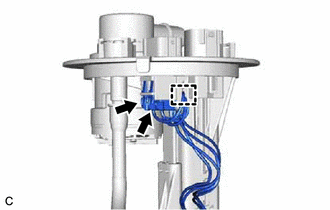

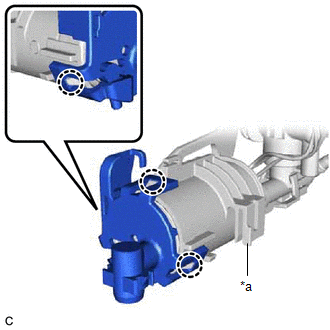

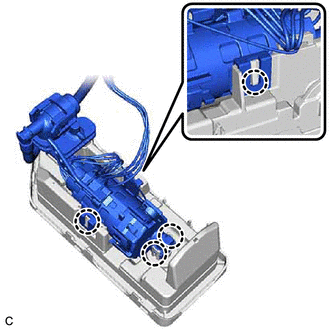

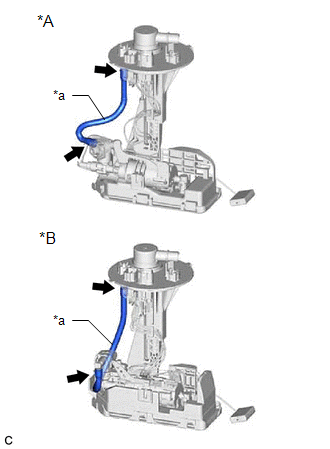

NOTICE:

Do not disconnect the tube shown in the illustration when disassembling the fuel suction tube with pump and gauge assembly. Doing so will cause reassembly of the fuel suction tube with pump and gauge assembly to be impossible as the tube is pressed into the fuel suction plate sub-assembly.

| *A | for Type A |

| *B | for Type B |

| *a | Tube |

PROCEDURE

1. REMOVE FUEL SENDER GAUGE ASSEMBLY

Click here .gif)

.gif)

2. REMOVE FUEL PUMP

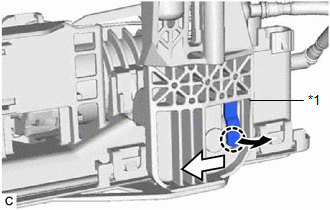

(a) for Type A:

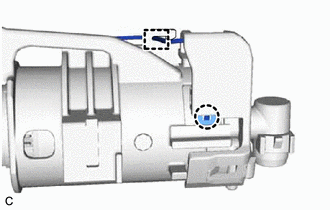

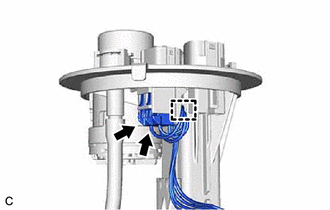

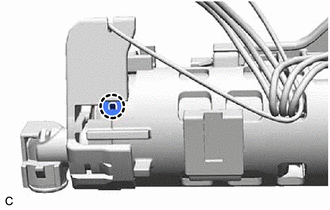

| (1) Disengage the clamp to disconnect the fuel pump harness from the fuel suction plate sub-assembly. NOTICE:

|

|

(2) Disconnect the 2 fuel pump harness connectors.

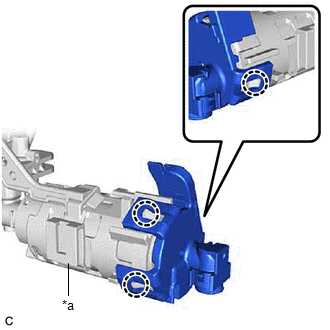

(3) Disengage the claw and slide the fuel suction plate sub-assembly and then separate it from the fuel sub-tank sub-assembly.

| *1 | Fuel Suction Plate Sub-assembly |

.png) | Pull |

.png) | Slide |

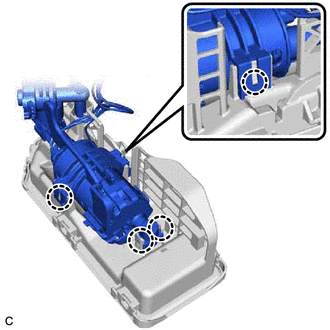

| (4) Disengage the 4 claws and remove the fuel suction plate sub-assembly from the fuel sub-tank sub-assembly. |

|

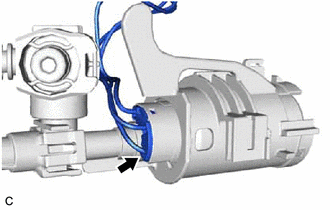

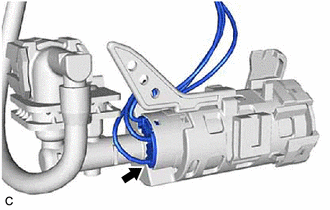

| (5) Disengage the claw and clamp, and disconnect the fuel pump harness. |

|

| (6) Disconnect the fuel pump harness connector. |

|

| (7) Disengage the 3 claws and remove the No. 2 fuel suction support from the fuel tube supporter. |

|

| (8) Remove the fuel pump from the fuel tube supporter. |

|

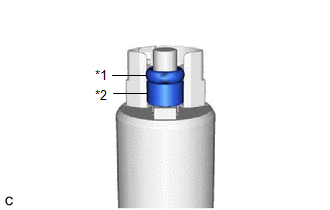

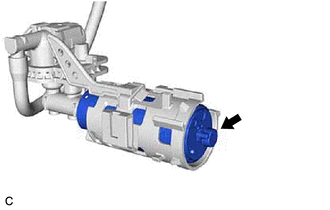

| (9) Remove the O-ring and fuel pump spacer from the fuel pump. |

|

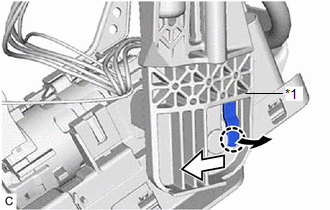

(b) for Type B:

| (1) Disengage the clamp to disconnect the fuel pump harness from the fuel suction plate sub-assembly. NOTICE:

|

|

(2) Disconnect the 2 fuel pump harness connectors.

(3) Disengage the claw and slide the fuel suction plate sub-assembly and then separate it from the fuel sub-tank sub-assembly.

| *1 | Fuel Suction Plate Sub-assembly |

.png) | Pull |

.png) | Slide |

| (4) Disengage the 4 claws and remove the fuel suction plate sub-assembly from the fuel sub-tank sub-assembly. |

|

| (5) Disengage the claw and disconnect the fuel pump harness. |

|

| (6) Disconnect the fuel pump harness connector. |

|

| (7) Disengage the 3 claws and remove the No. 2 fuel suction support from the fuel tube supporter. |

|

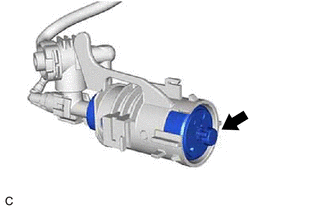

| (8) Remove the fuel pump from the fuel tube supporter. |

|

| (9) Remove the O-ring and fuel pump spacer from the fuel pump. |

|