Lexus ES: Disassembly

DISASSEMBLY

PROCEDURE

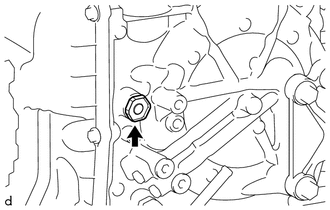

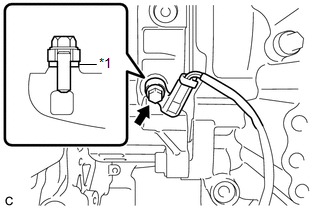

1. REMOVE TRANSMISSION CONTROL SHAFT LEVER

| (a) Remove the nut, washer and transmission control shaft lever from the manual valve lever shaft sub-assembly. |

|

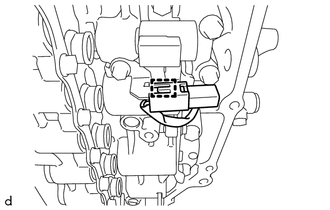

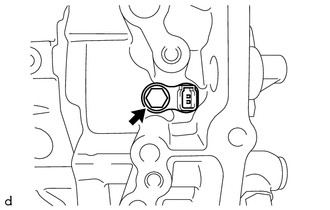

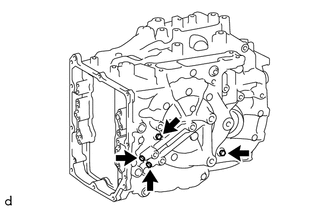

2. REMOVE PARK/NEUTRAL POSITION SWITCH ASSEMBLY

| (a) Remove the 2 bolts and park/neutral position switch assembly from the automatic transaxle case sub-assembly. |

|

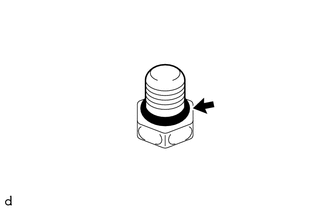

3. REMOVE REFILL PLUG

| (a) Remove the refill plug and gasket from the automatic transaxle case sub-assembly. |

|

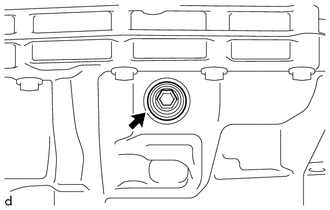

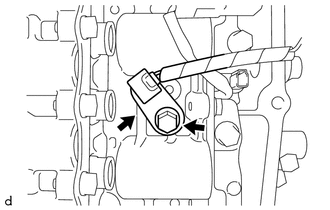

4. REMOVE OVERFLOW PLUG

| (a) Using a 10 mm socket hexagon wrench, remove the overflow plug and gasket from the transaxle housing. |

|

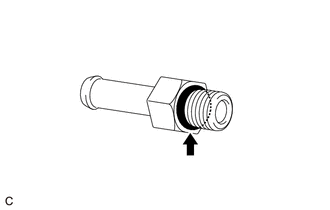

5. REMOVE NO. 1 TRANSMISSION OIL FILLER TUBE

| (a) Using a 6 mm socket hexagon wrench, remove the No. 1 transmission oil filler tube from the transaxle housing. |

|

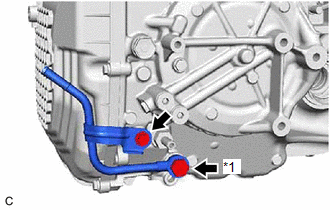

6. REMOVE OIL COOLER UNION SUB-ASSEMBLY

| (a) Remove the bolt to separate the oil cooler union sub-assembly bracket portion from the automatic transaxle case sub-assembly. |

|

(b) Remove the oil cooler union bolt, 2 gaskets and oil cooler union sub-assembly from the automatic transaxle case sub-assembly.

7. REMOVE NO. 1 OIL COOLER OUTLET TUBE SUB-ASSEMBLY

| (a) Using a 19 mm union nut wrench, remove the No. 1 oil cooler outlet tube sub-assembly from the automatic transaxle case sub-assembly. |

|

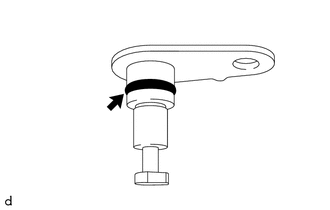

| (b) Remove the O-ring from the No. 1 oil cooler outlet tube sub-assembly. |

|

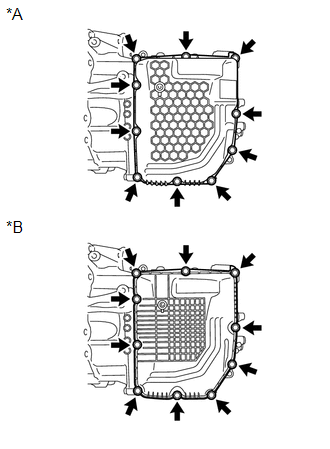

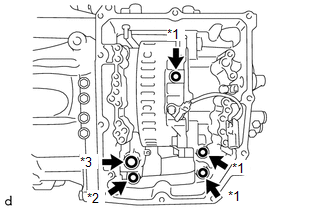

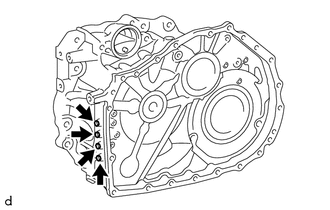

8. REMOVE TRANSMISSION CASE SIDE COVER

| (a) Remove the 10 bolts and transmission case side cover from the automatic transaxle case sub-assembly. |

|

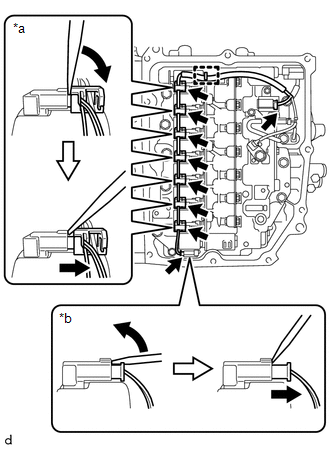

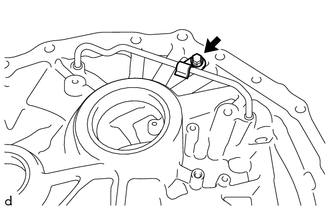

9. REMOVE TRANSMISSION WIRE

| (a) Disengage the clamp to disconnect the transmission wire from the solenoid lock plate. |

|

(b) Disconnect the 9 solenoid valve connectors.

HINT:

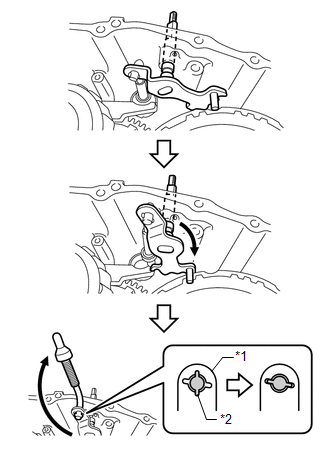

- Using a screwdriver, disconnect the solenoid valve connector A using the procedure shown in the illustration.

- Using a screwdriver, disconnect the solenoid valve connector B using the procedure shown in the illustration.

| (c) Remove the bolt and temperature sensor clamp and disconnect the temperature sensor from the transmission valve body assembly. |

|

| (d) Disconnect the transmission revolution sensor (NT) connector and transmission revolution sensor (NC) connector. |

|

| (e) Remove the bolt and transmission wire from the automatic transmission case sub-assembly. |

|

10. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

| (a) Disengage the clamp to disconnect the transmission revolution sensor (NC) wire connector. |

|

| (b) Remove the 9 bolts and transmission valve body assembly from the automatic transaxle case sub-assembly. |

|

| (c) Remove the 2 transaxle case gaskets from the automatic transaxle case sub-assembly. |

|

(d) Remove the transaxle case gasket from the counter drive gear sub-assembly.

(e) Remove the No. 1 front oil pump cover gasket from the front oil pump assembly.

(f) Remove the No. 2 front oil pump cover gasket from the front oil pump assembly.

11. REMOVE TRANSMISSION REVOLUTION SENSOR (NT)

| (a) Remove the bolt and transmission revolution sensor (NT) from the automatic transaxle case sub-assembly. |

|

12. REMOVE TRANSMISSION REVOLUTION SENSOR (NC)

| (a) Remove the bolt, spacer and transmission revolution sensor (NC) from the counter drive gear sub-assembly. |

|

13. INSPECT INPUT SHAFT END PLAY

Click here .gif)

14. REMOVE TRANSAXLE HOUSING

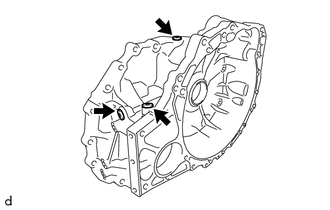

| (a) Remove the 21 bolts. |

|

| (b) Using a plastic hammer, tap on the circumference of the transaxle housing to remove it from the automatic transaxle case sub-assembly. |

|

| (c) Remove the 5 transaxle case gaskets from the front oil pump assembly. |

|

(d) Remove the O-ring from the automatic transaxle case sub-assembly.

15. REMOVE TRANSAXLE HOUSING OIL SEPARATOR

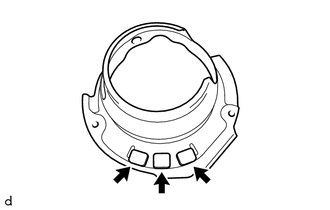

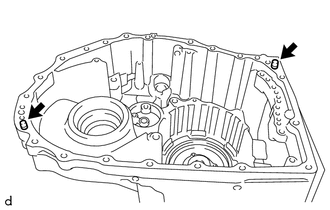

| (a) Remove the 3 bolts and transaxle housing oil separator from the transaxle housing. |

|

16. REMOVE TRANSMISSION OIL CLEANER MAGNET

| (a) Remove the 3 transmission oil cleaner magnets from the transaxle housing oil separator. |

|

17. INSPECT TRANSMISSION OIL CLEANER MAGNET

Click here .gif)

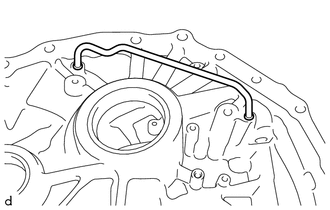

18. REMOVE DIFFERENTIAL GEAR LUBE APPLY TUBE

| (a) Remove the differential gear lube apply tube from the transaxle housing. |

|

19. REMOVE TRANSMISSION LUBE APPLY TUBE

| (a) Remove the bolt and clamp from the transaxle housing. |

|

| (b) Remove the transmission lube apply tube from the transaxle housing. |

|

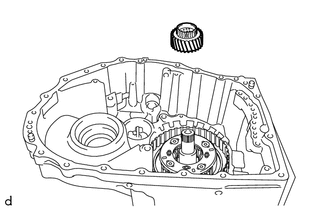

20. REMOVE DIFFERENTIAL CASE ASSEMBLY

| (a) Remove the differential case assembly from the automatic transaxle case sub-assembly. |

|

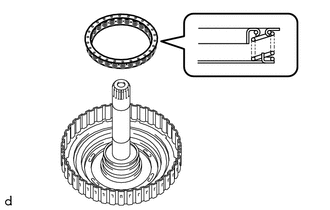

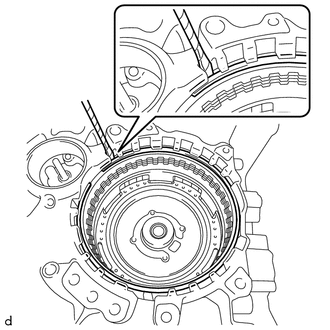

21. REMOVE CLUTCH DRUM OIL SEAL RING

| (a) Remove the clutch drum oil seal ring from the front oil pump assembly. |

|

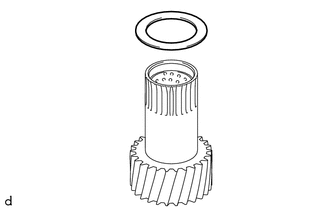

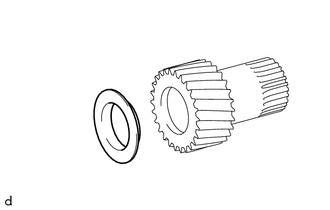

22. REMOVE OIL PUMP SPROCKET FRONT THRUST WASHER

| (a) Remove the oil pump sprocket front thrust washer from the transmission oil pump drive sprocket. |

|

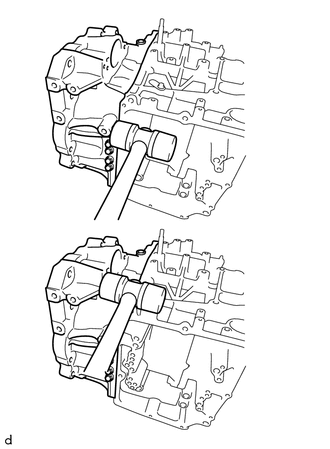

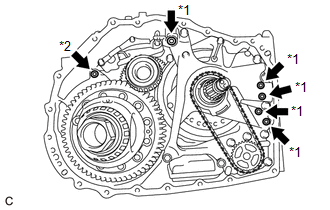

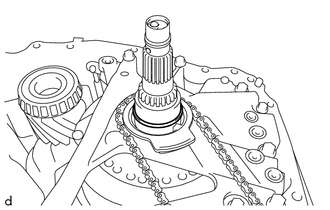

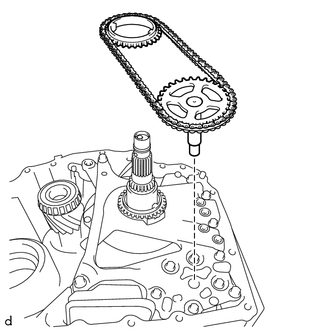

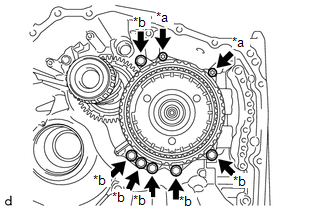

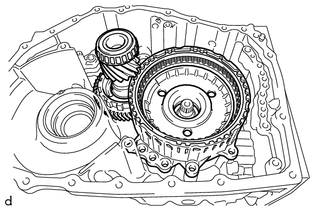

23. REMOVE TRANSMISSION DRIVE CHAIN

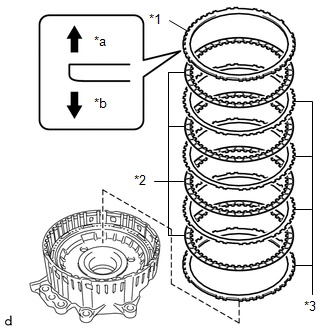

| (a) Remove the transmission drive chain together with the transmission oil pump drive sprocket and oil pump drive shaft sub-assembly from the front oil pump assembly. NOTICE: To avoid damaging the bush of the front oil pump assembly, remove the transmission drive chain, transmission oil pump drive sprocket and oil pump drive shaft sub-assembly horizontally relative to the front oil pump assembly. |

|

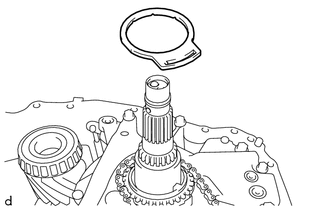

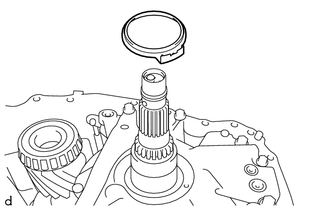

24. REMOVE OIL PUMP SPROCKET REAR THRUST WASHER

| (a) Remove the oil pump sprocket rear thrust washer from the front oil pump assembly. |

|

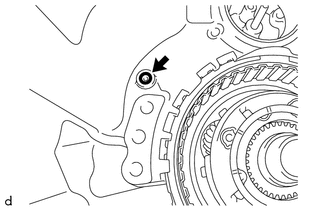

25. REMOVE MANUAL DETENT SPRING SUB-ASSEMBLY

| (a) Remove the bolt and manual detent spring sub-assembly from the front oil pump assembly. |

|

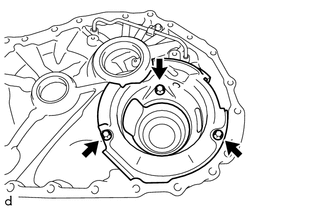

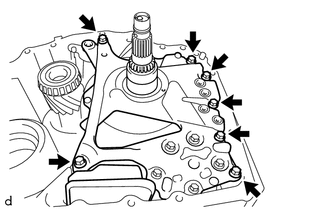

26. REMOVE FRONT OIL PUMP ASSEMBLY

NOTICE:

To avoid damaging the front oil pump assembly and transmission valve body assembly, when removing the front oil pump assembly, first remove the transmission valve body assembly.

| (a) Remove the 7 bolts and front oil pump assembly from the automatic transaxle case sub-assembly. |

|

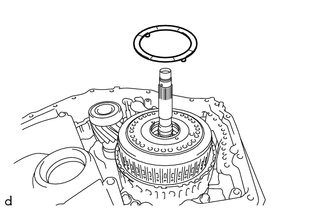

27. REMOVE PLANETARY CARRIER THRUST WASHER

| (a) Remove the planetary carrier thrust washer from the C-3 and C-4 clutch assembly. |

|

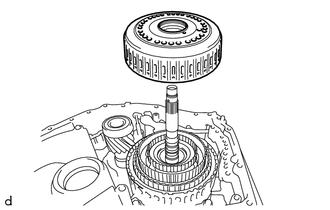

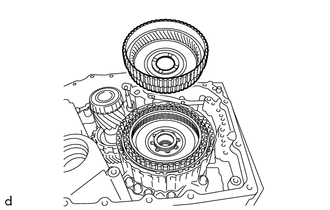

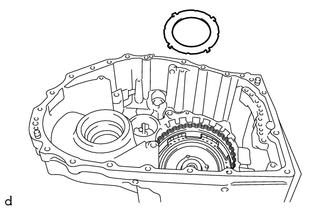

28. REMOVE C-3 AND C-4 CLUTCH ASSEMBLY

| (a) Remove the C-3 and C-4 clutch assembly from the front planetary gear assembly. |

|

29. INSPECT CLEARANCE OF C-3 CLUTCH

Click here .gif)

30. INSPECT CLEARANCE OF C-4 CLUTCH

Click here .gif)

31. REMOVE NO. 2 PLANETARY CARRIER THRUST WASHER

| (a) Remove the No. 2 planetary carrier thrust washer from the front planetary gear assembly. |

|

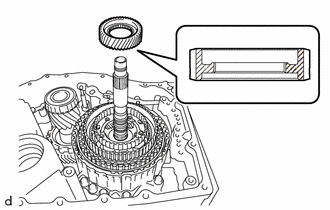

32. REMOVE PLANETARY SUN GEAR

| (a) Remove the planetary sun gear from the front planetary gear assembly. |

|

33. REMOVE NO. 9 THRUST BEARING RACE

| (a) Remove the No. 9 thrust bearing race from the front planetary gear assembly. |

|

34. REMOVE THRUST NEEDLE ROLLER BEARING

| (a) Remove the thrust needle roller bearing from the front planetary gear assembly. |

|

35. REMOVE NO. 8 THRUST BEARING RACE

| (a) Remove the No. 8 thrust bearing race from the front planetary gear assembly. |

|

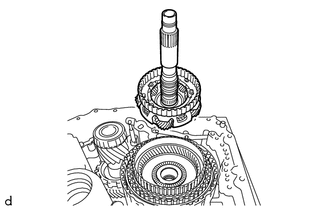

36. REMOVE FRONT PLANETARY GEAR ASSEMBLY

| (a) Remove the front planetary gear assembly from the front planetary ring gear. |

|

37. REMOVE THRUST NEEDLE ROLLER BEARING

| (a) Remove the thrust needle roller bearing from the front planetary ring gear. |

|

38. REMOVE NO. 7 THRUST BEARING RACE

| (a) Remove the No. 7 thrust bearing race from the front planetary gear assembly. |

|

39. INSPECT FRONT PLANETARY GEAR ASSEMBLY

Click here .gif)

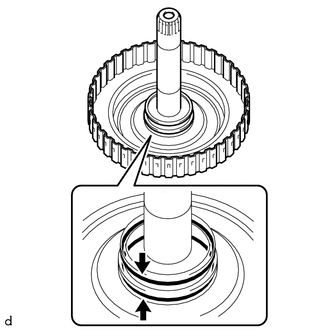

40. REMOVE INPUT SHAFT OIL SEAL RING

| (a) Remove the 5 input shaft oil seal rings from the front planetary gear assembly. |

|

41. REMOVE REAR INPUT SHAFT OIL SEAL RING

| (a) Remove the 2 rear input shaft oil seal rings from the front planetary gear assembly. |

|

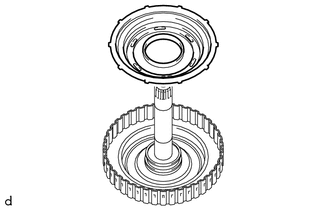

42. REMOVE FRONT PLANETARY RING GEAR

| (a) Remove the front planetary ring gear with front planetary ring gear flange from the C-1 clutch assembly. |

|

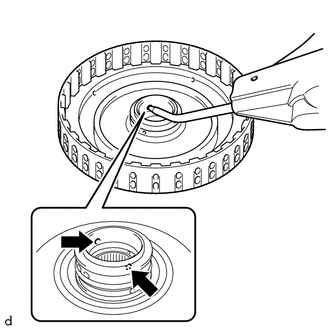

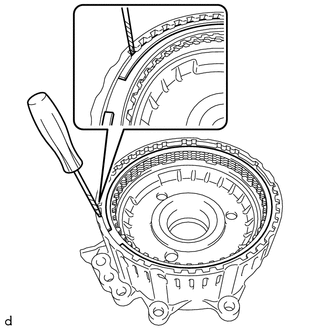

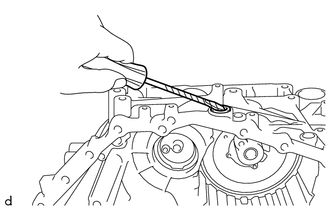

| (b) Using a screwdriver with its tip wrapped with protective tape, remove the snap ring from the front planetary ring gear. NOTICE: Be careful not to damage the front planetary ring gear and front planetary ring gear flange. |

|

| (c) Remove the front planetary ring gear flange from the front planetary ring gear. |

|

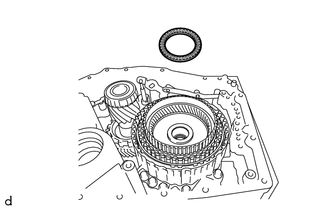

43. REMOVE THRUST NEEDLE ROLLER BEARING

| (a) Remove the thrust needle roller bearing from the C-1 clutch assembly. |

|

44. REMOVE NO. 6 THRUST BEARING RACE

| (a) Remove the No. 6 thrust bearing race from the C-1 clutch assembly. |

|

45. REMOVE C-1 CLUTCH ASSEMBLY

| (a) Remove the C-1 clutch assembly from the sun gear input hub sub-assembly. |

|

46. INSPECT CLEARANCE OF C-1 CLUTCH

Click here .gif)

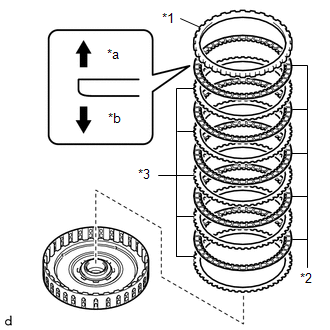

47. REMOVE FRONT CLUTCH CLUTCH DISC

| (a) Using a screwdriver with its tip wrapped in protective tape, remove the snap ring from the clutch drum sub-assembly. NOTICE: Be careful not to damage the clutch drum sub-assembly. |

|

| (b) Remove the forward clutch flange, 5 front clutch clutch discs and 5 forward multiple disc clutch clutch plates from the clutch drum sub-assembly. |

|

48. INSPECT FRONT CLUTCH CLUTCH DISC

Click here .gif)

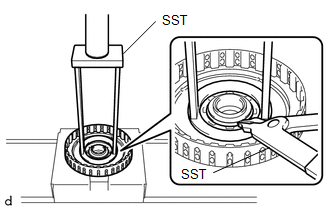

49. REMOVE NO. 1 CLUTCH BALANCER

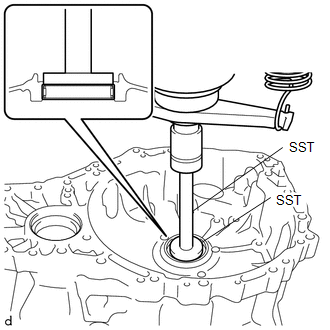

| (a) Place SST on the No. 1 clutch balancer and compress the rear clutch piston return compression spring with a press. SST: 09387-00020 NOTICE: Do not compress the rear clutch piston return compression spring excessively. |

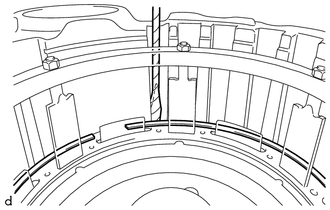

|

(b) Using SST, remove the snap ring from the clutch drum sub-assembly.

SST: 09350-30020

09350-07070

| (c) Remove the No. 1 clutch balancer from the forward clutch piston. |

|

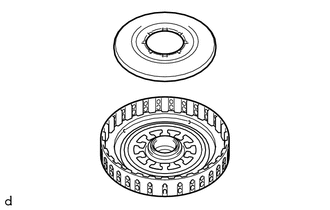

50. REMOVE REAR CLUTCH PISTON RETURN COMPRESSION SPRING

| (a) Remove the rear clutch piston return compression spring from the forward clutch piston. |

|

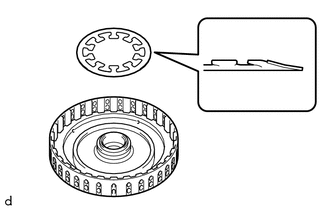

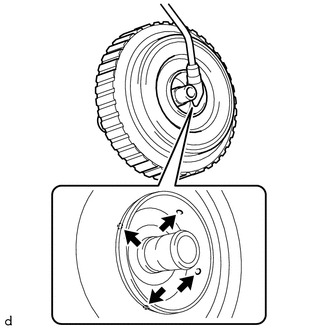

51. REMOVE FORWARD CLUTCH PISTON

| (a) Apply compressed air (392 kPa (4.0 kgf/cm2, 57 psi)) to the oil hole of the clutch drum sub-assembly to remove the forward clutch piston from the clutch drum sub-assembly. NOTICE:

|

|

| (b) Remove the O-ring from the clutch drum sub-assembly. |

|

| (c) Remove the D-ring from the clutch drum sub-assembly. |

|

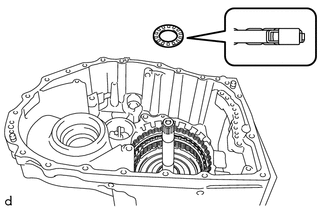

52. REMOVE SUN GEAR INPUT HUB SUB-ASSEMBLY

| (a) Remove the sun gear input hub sub-assembly from the counter drive gear sub-assembly. |

|

53. REMOVE THRUST NEEDLE ROLLER BEARING

| (a) Remove the thrust needle roller bearing from the sun gear input hub sub-assembly. |

|

54. REMOVE NO. 5 THRUST BEARING RACE

| (a) Remove the No. 5 thrust bearing race from the sun gear input hub sub-assembly. |

|

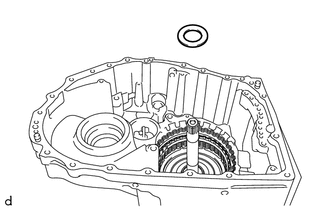

55. REMOVE MANUAL VALVE LEVER SHAFT SUB-ASSEMBLY

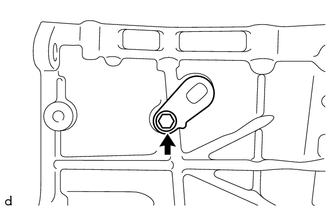

| (a) Remove the bolt. |

|

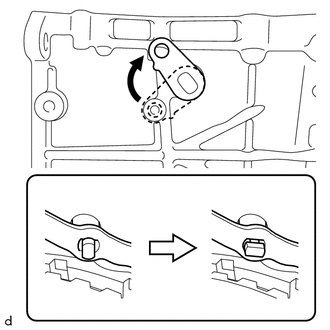

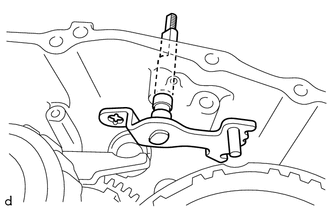

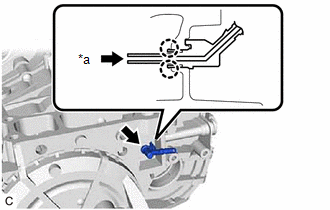

| (b) Align the cutouts of the manual valve lever sub-assembly and manual valve lever shaft sub-assembly, and remove the manual valve lever shaft sub-assembly. HINT: Rotating the manual valve lever shaft sub-assembly to the area shown in the illustration will align the cutouts. |

|

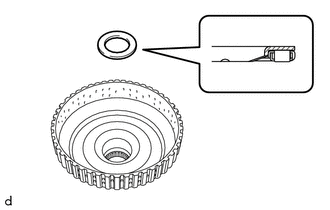

| (c) Remove the O-ring from the manual valve lever shaft sub-assembly. |

|

56. REMOVE MANUAL VALVE LEVER SUB-ASSEMBLY

| (a) Remove the manual valve lever sub-assembly from the automatic transaxle case sub-assembly. |

|

57. REMOVE PAWL STOPPER PLATE

| (a) Remove the 2 bolts and pawl stopper plate from the automatic transaxle case sub-assembly. |

|

58. REMOVE MANUAL VALVE LEVER SHAFT RETAINER SPRING

| (a) Remove the manual valve lever shaft retainer spring from the automatic transaxle case sub-assembly. |

|

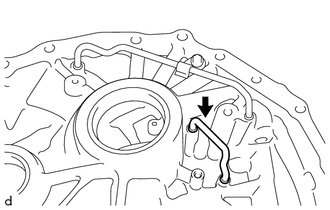

59. REMOVE PARKING LOCK ROD SUB-ASSEMBLY

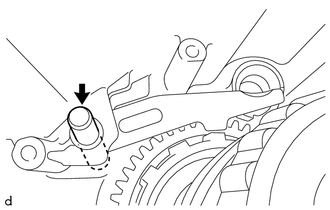

| (a) Move the manual valve lever shaft sub-assembly and parking lock rod sub-assembly as shown in the illustration, and remove the parking lock rod sub-assembly. HINT: Align the cutouts of the parking lock rod sub-assembly and manual valve lever shaft sub-assembly and remove the parking lock rod sub-assembly. |

|

60. REMOVE MANUAL VALVE LEVER SHAFT SUB-ASSEMBLY

| (a) Remove the manual valve lever shaft sub-assembly from the automatic transaxle case sub-assembly. |

|

61. REMOVE PARKING LOCK PAWL TORSION SPRING

| (a) Remove the parking lock pawl torsion spring from the automatic transaxle case sub-assembly. |

|

62. REMOVE PARKING LOCK PAWL SHAFT

| (a) Remove the parking lock pawl shaft from the automatic transaxle case sub-assembly. |

|

63. REMOVE PARKING LOCK PAWL

| (a) Remove the parking lock pawl from the automatic transaxle case sub-assembly. |

|

64. REMOVE PARKING LOCK SLEEVE

| (a) Remove the parking lock sleeve from the automatic transaxle case sub-assembly. |

|

65. INSPECT CLEARANCE OF B-1 BRAKE

Click here .gif)

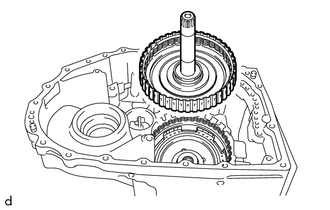

66. REMOVE COUNTER DRIVE GEAR SUB-ASSEMBLY

| (a) Using a T50 "TORX" socket wrench, remove the 2 bolts (A) from the counter drive gear sub-assembly. |

|

(b) Remove the 6 bolts (B) from the counter drive gear sub-assembly.

| (c) Remove the counter drive gear sub-assembly together with the pinion and counter driven gear sub-assembly from the automatic transaxle case sub-assembly. |

|

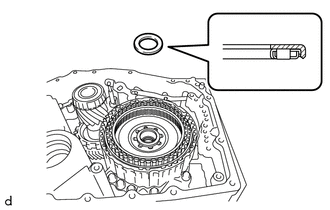

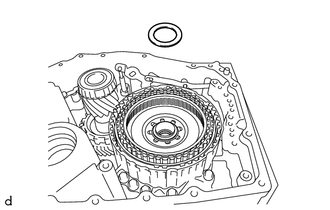

| (d) Remove the O-ring from the automatic transaxle case sub-assembly. |

|

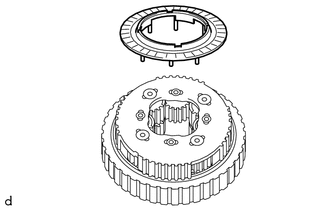

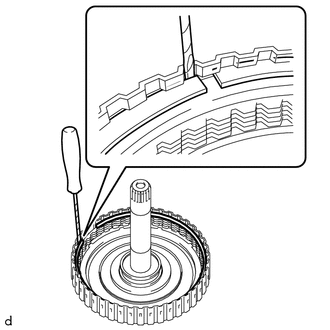

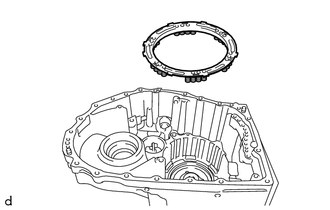

67. REMOVE NO. 1 BRAKE DISC

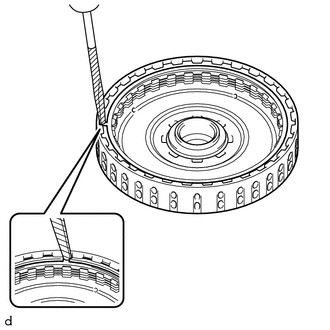

| (a) Using a screwdriver with its tip wrapped in protective tape, remove the snap ring from the counter drive gear sub-assembly. NOTICE: Be careful not to damage the counter drive gear sub-assembly. |

|

| (b) Remove the No. 1 brake flange, 4 No. 1 brake discs and 4 No. 1 brake plates from the counter drive gear sub-assembly. |

|

68. INSPECT NO. 1 BRAKE DISC

Click here .gif)

69. REMOVE NO. 3 PLANETARY CARRIER THRUST WASHER

| (a) Remove the No. 3 planetary carrier thrust washer from the rear planetary gear assembly. |

|

70. REMOVE PLANETARY SUN GEAR SUB-ASSEMBLY

| (a) Remove the planetary sun gear sub-assembly from the rear planetary gear assembly. |

|

71. INSPECT PLANETARY SUN GEAR SUB-ASSEMBLY

Click here .gif)

72. REMOVE REAR PLANETARY SUN GEAR SUB-ASSEMBLY

| (a) Remove the rear planetary sun gear sub-assembly from the C-2 clutch assembly. |

|

73. REMOVE REAR PLANETARY GEAR ASSEMBLY

| (a) Remove the rear planetary gear assembly from the C-2 clutch assembly. |

|

74. REMOVE NO. 4 PLANETARY CARRIER THRUST WASHER

| (a) Remove the No. 4 planetary carrier thrust washer from the rear planetary gear assembly. |

|

75. INSPECT REAR PLANETARY GEAR ASSEMBLY

Click here .gif)

76. REMOVE NO. 4 THRUST BEARING RACE

| (a) Remove the No. 4 thrust bearing race from the rear planetary sun gear sub-assembly. |

|

77. REMOVE THRUST NEEDLE ROLLER BEARING

| (a) Remove the thrust needle roller bearing from the rear planetary sun gear sub-assembly. |

|

78. REMOVE THRUST BEARING RACE

| (a) Remove the thrust bearing race from the rear planetary sun gear sub-assembly. |

|

79. REMOVE NO. 3 THRUST BEARING RACE

| (a) Remove the No. 3 thrust bearing race from the rear planetary sun gear sub-assembly. |

|

80. INSPECT REAR PLANETARY SUN GEAR SUB-ASSEMBLY

Click here .gif)

81. REMOVE THRUST NEEDLE ROLLER BEARING

| (a) Remove the thrust needle roller bearing from the C-2 clutch assembly. |

|

82. REMOVE NO. 2 THRUST BEARING RACE

| (a) Remove the No. 2 thrust bearing race from the C-2 clutch assembly. |

|

83. INSPECT CLEARANCE OF C-2 CLUTCH

Click here .gif)

84. REMOVE C-2 CLUTCH ASSEMBLY

| (a) Remove the C-2 clutch assembly from the automatic transaxle case sub-assembly. |

|

85. REMOVE THRUST NEEDLE ROLLER BEARING

| (a) Remove the thrust needle roller bearing from the C-2 clutch assembly. |

|

86. REMOVE NO. 1 THRUST BEARING RACE

| (a) Remove the No. 1 thrust bearing race from the automatic transaxle case sub-assembly. |

|

87. REMOVE NO. 2 CLUTCH DISC

| (a) Using a screwdriver with its tip wrapped in protective tape, remove the snap ring from the intermediate shaft sub-assembly. NOTICE: Be careful not to damage the intermediate shaft sub-assembly. |

|

| (b) Remove the direct clutch flange, 4 No. 2 clutch discs and 4 No. 2 clutch plates from the intermediate shaft sub-assembly. |

|

88. INSPECT NO. 2 CLUTCH DISC

Click here .gif)

89. REMOVE C-2 CLUTCH BALANCER

| (a) Place SST on the C-2 clutch balancer and compress the clutch return spring sub-assembly with a press. SST: 09387-00020 NOTICE: Do not compress the clutch return spring sub-assembly excessively. |

|

(b) Using SST, remove the snap ring from the intermediate shaft sub-assembly.

SST: 09350-30020

09350-07070

| (c) Remove the C-2 clutch balancer from the intermediate shaft sub-assembly. |

|

90. REMOVE CLUTCH RETURN SPRING SUB-ASSEMBLY

| (a) Remove the clutch return spring sub-assembly from the intermediate shaft sub-assembly. |

|

91. INSPECT CLUTCH RETURN SPRING SUB-ASSEMBLY

Click here .gif)

92. REMOVE C-2 CLUTCH PISTON

| (a) Apply compressed air (392 kPa (4.0 kgf/cm2, 57 psi)) to the oil hole of the intermediate shaft sub-assembly. NOTICE:

|

|

| (b) Remove the C-2 clutch piston from the intermediate shaft sub-assembly. |

|

| (c) Remove the 2 O-rings from the intermediate shaft sub-assembly. |

|

93. REMOVE DIRECT CLUTCH DRUM OIL SEAL RING

| (a) Remove the 2 direct clutch drum oil seal rings from the automatic transaxle case sub-assembly. |

|

94. INSPECT CLEARANCE OF B-2 BRAKE

Click here .gif)

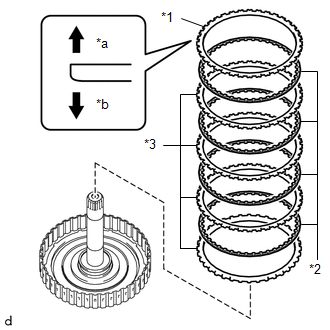

95. REMOVE 2ND BRAKE BRAKE DISC

| (a) Using a screwdriver with its tip wrapped with protective tape, remove the snap ring from the automatic transaxle case sub-assembly. NOTICE: Be careful not to damage the automatic transaxle case sub-assembly. |

|

| (b) Remove the 2nd brake brake flange, 5 2nd brake brake discs and 5 2nd brake brake plates from the automatic transaxle case sub-assembly. |

|

96. INSPECT 2ND BRAKE BRAKE DISC

Click here .gif)

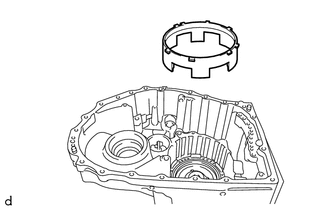

97. REMOVE NO. 2 1ST AND REVERSE BRAKE PISTON

| (a) Remove the No. 2 1st and reverse brake piston from the automatic transaxle case sub-assembly. |

|

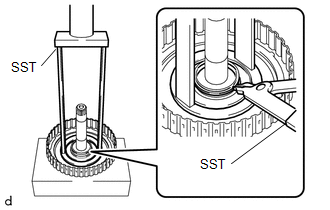

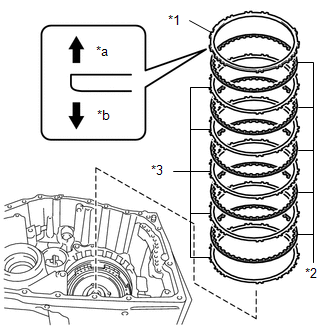

98. REMOVE 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

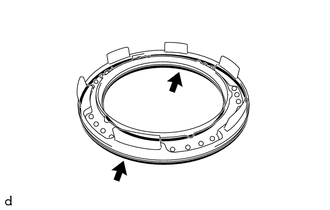

| (a) Place SST on the 1st and reverse brake return spring sub-assembly and compress it with a press. SST: 09380-60011 09381-06020 09381-06050 09381-06060 09381-06100 09381-06110 SST: 09950-70010 09951-07200 NOTICE: Do not compress the 1st and reverse brake return spring sub-assembly excessively. |

|

| (b) Using a screwdriver with its tip wrapped with protective tape, remove the snap ring from the automatic transaxle case sub-assembly. NOTICE: Be careful not to damage the automatic transaxle case sub-assembly. |

|

| (c) Remove the 1st and reverse brake return spring sub-assembly from the automatic transaxle case sub-assembly. |

|

99. INSPECT 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

Click here .gif)

100. REMOVE 1ST AND REVERSE BRAKE PISTON

| (a) Apply compressed air (approximately 392 kPa (4.0 kgf/cm2, 57 psi)) to the ATF hole to remove the 1st and reverse brake piston from the automatic transaxle case sub-assembly. |

|

| (b) Remove the 2 O-rings from the 1st and reverse brake piston. |

|

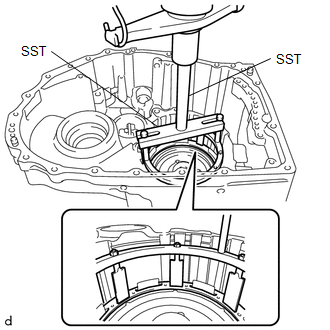

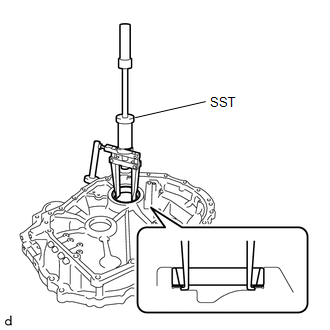

101. REMOVE NEEDLE ROLLER BEARING

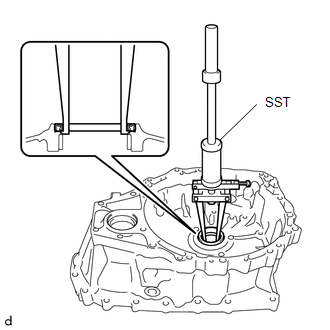

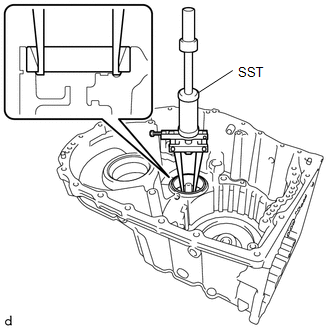

| (a) Using SST, remove the needle roller bearing from the automatic transaxle case sub-assembly. SST: 09303-55010 SST: 09502-12010 NOTICE: Be careful not to damage the automatic transaxle case sub-assembly. |

|

102. REMOVE MANUAL VALVE LEVER SHAFT OIL SEAL

| (a) Using a screwdriver with its tip wrapped with protective tape, remove the manual valve lever shaft oil seal from the automatic transaxle case sub-assembly. NOTICE: Be careful not to damage the automatic transaxle case sub-assembly. |

|

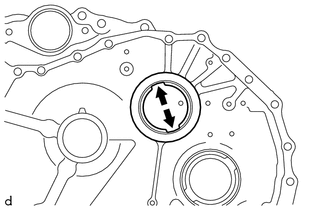

103. REMOVE TRANSAXLE CASE OIL SEAL

| (a) Using SST, remove the transaxle case oil seal from the transaxle housing. SST: 09308-36010 NOTICE: Be careful not to damage the transaxle housing. |

|

104. REMOVE FRONT DRIVE SHAFT OIL SEAL RH

| (a) Using SST, remove the front drive shaft oil seal RH from the transaxle housing. SST: 09308-36010 NOTICE: Be careful not to damage the transaxle housing. |

|

105. REMOVE FRONT DRIVE SHAFT OIL SEAL LH

| (a) Using SST, remove the front drive shaft oil seal LH from the automatic transaxle case sub-assembly. SST: 09308-36010 NOTICE: Be careful not to damage the automatic transaxle case sub-assembly. |

|

106. REMOVE NEEDLE ROLLER BEARING

| (a) Using SST and a press, remove the needle roller bearing from the transaxle housing. SST: 09950-60011 09951-00550 SST: 09950-70010 09951-07200 NOTICE: Be careful not to damage the transaxle housing. |

|

107. REMOVE COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING (OUTER RACE)

(a) Using SST, remove the counter driven gear rear tapered roller bearing (outer race) from the automatic transaxle case sub-assembly.

SST: 09308-36010

NOTICE:

Be careful not to damage the automatic transaxle case sub-assembly.

HINT:

Align the claw of SST with the indentation of the automatic transaxle case sub-assembly when removing the parts.

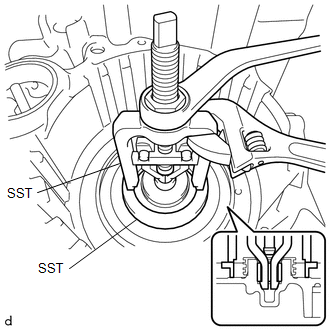

108. REMOVE COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING (INNER RACE)

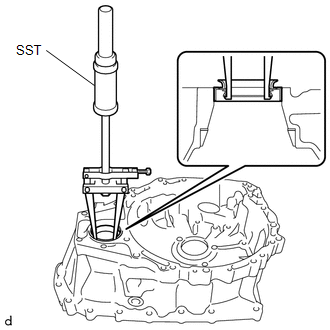

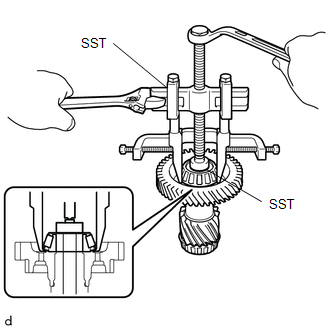

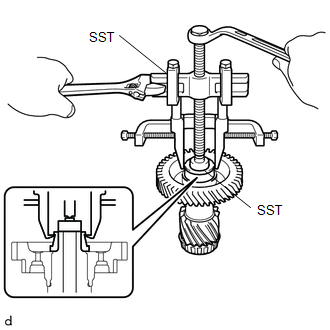

| (a) Using SST, remove the counter driven gear rear tapered roller bearing (inner race) from the pinion and counter driven gear sub-assembly. SST: 09950-40011 09951-04010 09952-04010 09953-04030 09954-04010 09955-04011 09957-04010 09958-04011 SST: 09950-60011 09951-00310 NOTICE: Because SST is attached to the roller portion, there is a possibility that the roller portion could break and SST could come off before the counter driven gear tapered roller bearing (rear side inner race) comes off. |

|

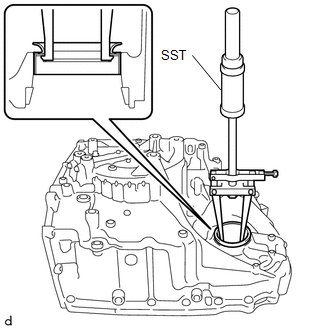

| (b) If the roller portion breaks and SST comes off, reattach SST to the inner race in the position shown in the illustration, and continue removing the parts. SST: 09950-40011 09951-04010 09952-04010 09953-04030 09954-04010 09955-04011 09957-04010 09958-04011 SST: 09950-60011 09951-00310 |

|

109. REMOVE COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING (OUTER RACE)

(a) Using SST, remove the counter driven gear front tapered roller bearing (outer race) and pinion and counter driven gear shim from the transaxle housing.

SST: 09308-36010

NOTICE:

Be careful not to damage the transaxle housing.

HINT:

Align the claw of SST with the indentation of the transaxle housing when removing the parts.

110. REMOVE COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING (INNER RACE)

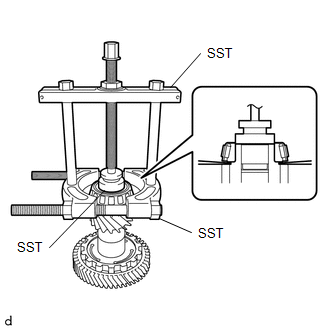

| (a) Using SST, remove the counter driven gear front tapered roller bearing (inner race) from the pinion and counter driven gear sub-assembly. SST: 09950-00020 SST: 09950-00030 SST: 09950-60011 09951-00380 |

|

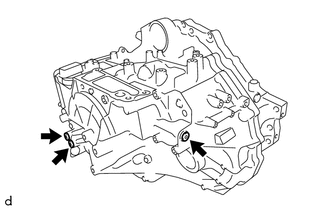

111. REMOVE NO. 1 TRANSAXLE CASE PLUG

| (a) Remove the 4 No. 1 transaxle case plugs from the automatic transaxle case sub-assembly. |

|

| (b) Remove the 4 No. 1 transaxle case plugs from the transaxle housing. |

|

| (c) Remove the 8 O-rings from the 8 No. 1 transaxle case plugs. |

|

112. REMOVE NO. 2 TRANSAXLE CASE PLUG

| (a) Using a 6 mm socket hexagon wrench, remove the 3 No. 2 transaxle case plugs and 3 gaskets from the automatic transaxle case sub-assembly. |

|

| (b) Using a 6 mm socket hexagon wrench, remove the 3 No. 2 transaxle case plugs and 3 gaskets from the transaxle housing. |

|

113. REMOVE AUTOMATIC TRANSMISSION CASE STRAIGHT PIN

NOTICE:

It is not necessary to remove the automatic transmission case straight pins unless they are being replaced.

| (a) Remove the 2 automatic transmission case straight pins from the automatic transaxle case sub-assembly. |

|

114. REMOVE NO. 1 BREATHER PLUG (ATM)

| (a) Disengage each claw and remove the No. 1 breather plug (ATM) from the automatic transaxle case sub-assembly. NOTICE: Be careful not to damage the automatic transaxle case sub-assembly. |

|