Lexus ES: Components

COMPONENTS

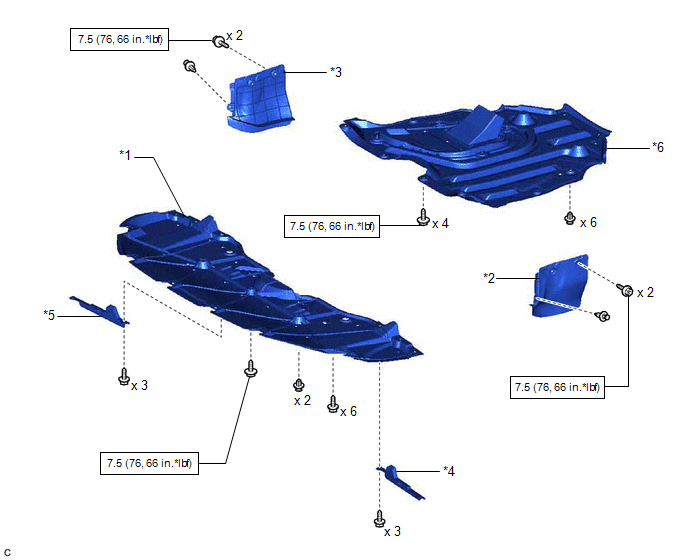

ILLUSTRATION

| *1 | NO. 1 ENGINE UNDER COVER | *2 | FRONT FENDER APRON SEAL LH |

| *3 | FRONT FENDER APRON SEAL RH | *4 | FRONT WHEEL OPENING EXTENSION PAD LH |

| *5 | FRONT WHEEL OPENING EXTENSION PAD RH | *6 | NO. 2 ENGINE UNDER COVER ASSEMBLY |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | - | - |

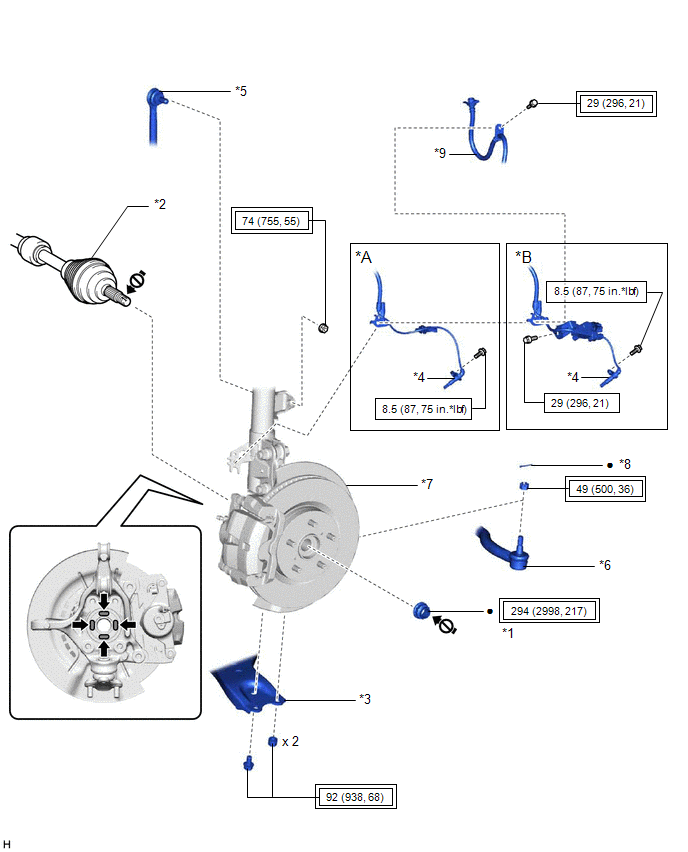

ILLUSTRATION

| *A | w/o AVS | *B | w/ AVS |

| *1 | FRONT AXLE SHAFT NUT | *2 | FRONT DRIVE SHAFT ASSEMBLY |

| *3 | FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY | *4 | FRONT SPEED SENSOR |

| *5 | FRONT STABILIZER LINK ASSEMBLY | *6 | TIE ROD ASSEMBLY |

| *7 | FRONT AXLE ASSEMBLY | *8 | COTTER PIN |

| *9 | FRONT FLEXIBLE HOSE | - | - |

.png) | Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) | .png) | N*m (kgf*cm, ft.*lbf): Specified torque |

| ● | Non-reusable part | .png) | Toyota Body Grease W |

.png) | Do not apply lubricants to the threaded parts | - | - |

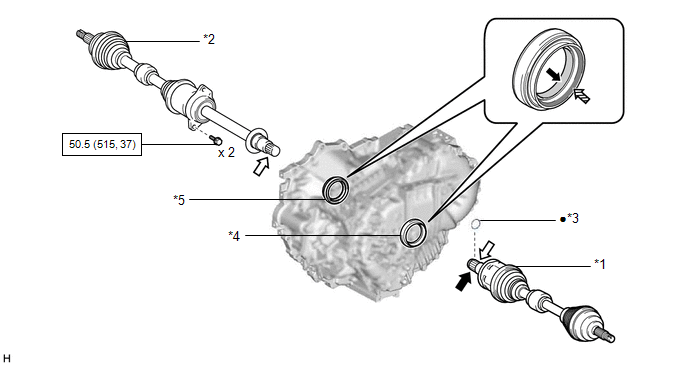

ILLUSTRATION

| *1 | FRONT DRIVE SHAFT ASSEMBLY LH | *2 | FRONT DRIVE SHAFT ASSEMBLY RH |

| *3 | FRONT DRIVE SHAFT HOLE SNAP RING | *4 | FRONT DRIVE SHAFT OIL SEAL LH |

| *5 | FRONT DRIVE SHAFT OIL SEAL RH | - | - |

.png) | N*m (kgf*cm, ft.*lbf): Specified torque | ● | Non-reusable part |

.png) | MP grease | .png) | Toyota Genuine ATF WS |

.png) | Toyota Genuine Oil Seal Side Lip Grease | - | - |

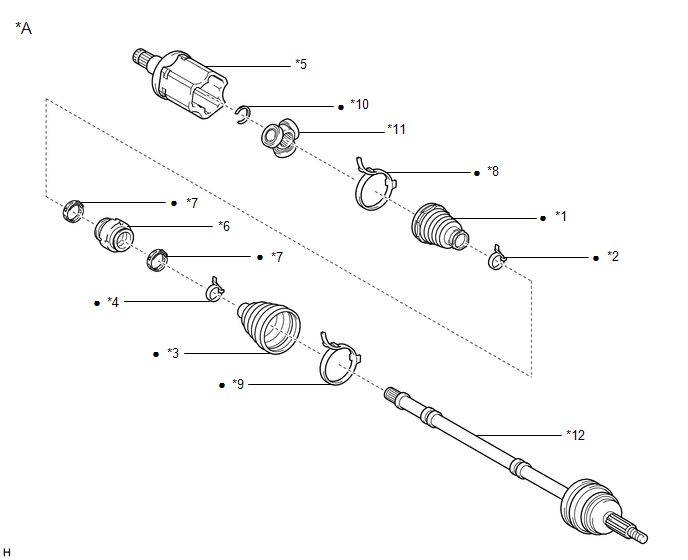

ILLUSTRATION

| *A | for TMC Made LH Side | - | - |

| *1 | FRONT AXLE INBOARD JOINT BOOT | *2 | FRONT AXLE INBOARD JOINT BOOT CLAMP |

| *3 | FRONT AXLE OUTBOARD JOINT BOOT | *4 | FRONT AXLE OUTBOARD JOINT BOOT CLAMP |

| *5 | FRONT DRIVE INBOARD JOINT ASSEMBLY | *6 | FRONT DRIVE SHAFT DAMPER |

| *7 | FRONT DRIVE SHAFT DAMPER CLAMP | *8 | FRONT NO. 2 AXLE INBOARD JOINT BOOT CLAMP |

| *9 | FRONT NO. 2 AXLE OUTBOARD JOINT BOOT CLAMP | *10 | SHAFT SNAP RING |

| *11 | TRIPOD JOINT | *12 | FRONT DRIVE OUTBOARD JOINT SHAFT ASSEMBLY |

| ● | Non-reusable part | - | - |

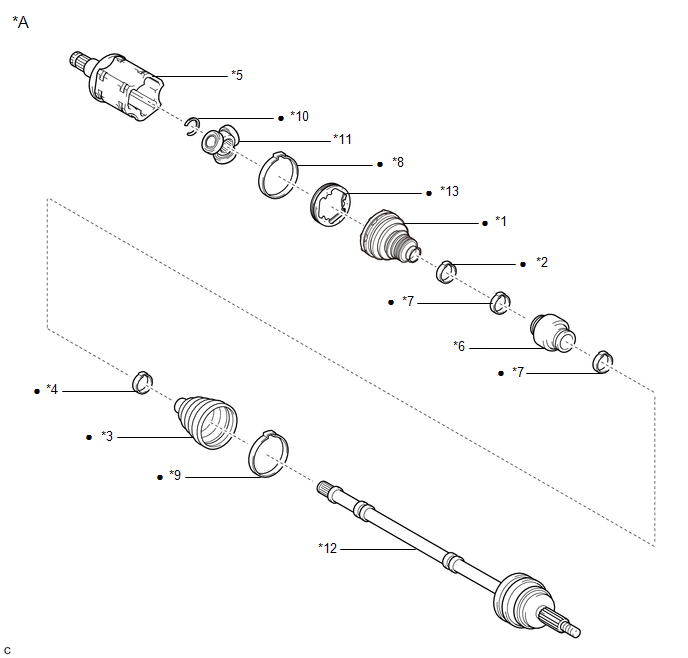

ILLUSTRATION

| *A | for TMMK Made LH Side | - | - |

| *1 | FRONT AXLE INBOARD JOINT BOOT | *2 | FRONT AXLE INBOARD JOINT BOOT CLAMP |

| *3 | FRONT AXLE OUTBOARD JOINT BOOT | *4 | FRONT AXLE OUTBOARD JOINT BOOT CLAMP |

| *5 | FRONT AXLE OUTBOARD JOINT BOOT | *6 | FRONT DRIVE SHAFT DAMPER |

| *7 | FRONT DRIVE SHAFT DAMPER CLAMP | *8 | FRONT NO. 2 AXLE INBOARD JOINT BOOT CLAMP |

| *9 | FRONT NO. 2 AXLE OUTBOARD JOINT BOOT CLAMP | *10 | SHAFT SNAP RING |

| *11 | TRIPOD JOINT | *12 | FRONT DRIVE OUTBOARD JOINT SHAFT ASSEMBLY |

| *13 | FRONT AXLE INBOARD JOINT GROMMET | - | - |

| ● | Non-reusable part | - | - |

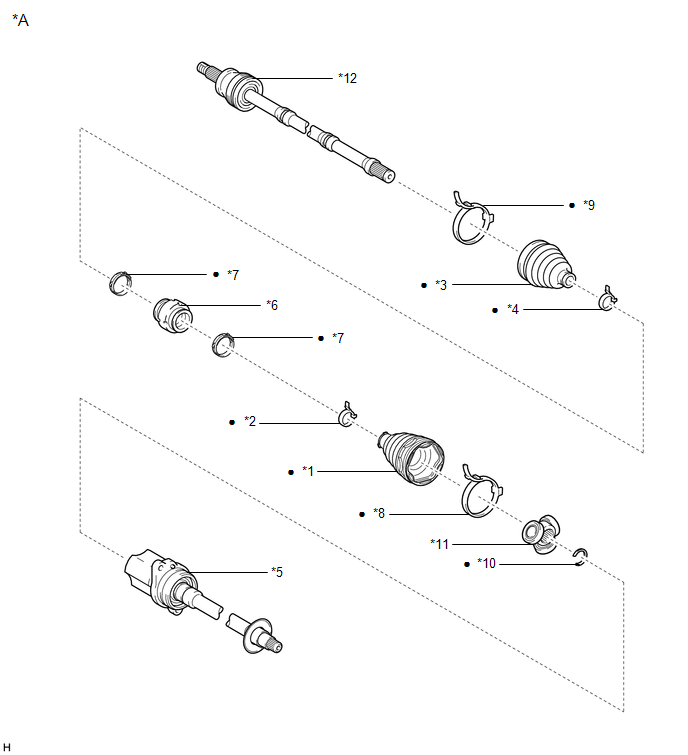

ILLUSTRATION

| *A | for TMC Made for RH Side | - | - |

| *1 | FRONT AXLE INBOARD JOINT BOOT | *2 | FRONT AXLE INBOARD JOINT BOOT CLAMP |

| *3 | FRONT AXLE OUTBOARD JOINT BOOT | *4 | FRONT AXLE OUTBOARD JOINT BOOT CLAMP |

| *5 | FRONT DRIVE INBOARD JOINT ASSEMBLY | *6 | FRONT DRIVE SHAFT DAMPER |

| *7 | FRONT DRIVE SHAFT DAMPER CLAMP | *8 | FRONT NO. 2 AXLE INBOARD JOINT BOOT CLAMP |

| *9 | FRONT NO. 2 AXLE OUTBOARD JOINT BOOT CLAMP | *10 | SHAFT SNAP RING |

| *11 | TRIPOD JOINT | *12 | FRONT DRIVE OUTBOARD JOINT SHAFT ASSEMBLY |

| ● | Non-reusable part | - | - |

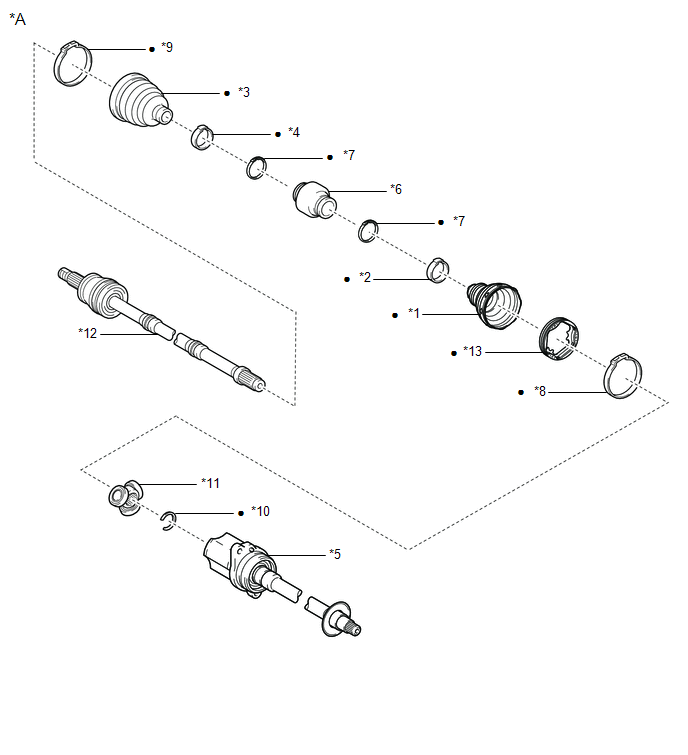

ILLUSTRATION

| *A | for TMMK Made RH Side | - | - |

| *1 | FRONT AXLE INBOARD JOINT BOOT | *2 | FRONT AXLE INBOARD JOINT BOOT CLAMP |

| *3 | FRONT AXLE OUTBOARD JOINT BOOT | *4 | FRONT AXLE OUTBOARD JOINT BOOT CLAMP |

| *5 | FRONT DRIVE INBOARD JOINT ASSEMBLY | *6 | FRONT DRIVE SHAFT DAMPER |

| *7 | FRONT DRIVE SHAFT DAMPER CLAMP | *8 | FRONT NO. 2 AXLE INBOARD JOINT BOOT CLAMP |

| *9 | FRONT NO. 2 AXLE OUTBOARD JOINT BOOT CLAMP | *10 | SHAFT SNAP RING |

| *11 | TRIPOD JOINT | *12 | FRONT DRIVE OUTBOARD JOINT SHAFT ASSEMBLY |

| *13 | FRONT AXLE INBOARD JOINT GROMMET | - | - |

| ● | Non-reusable part | - | - |