Lexus ES: Bleeding

BLEEDING

CAUTION / NOTICE / HINT

NOTICE:

- Move the shift lever to P and apply the parking brake before bleeding the brakes.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

- If brake fluid leaks onto any painted surface, immediately wash it off.

- Do not operate the brake actuator assembly while air is in the brake system or in the brake master cylinder sub-assembly. Doing so may cause air to enter the brake actuator assembly.

- If bleeding the brake actuator assembly is difficult due to air in the brake actuator assembly, replace it with a new one.

-

When bleeding air, select the suitable procedure listed below.

Replaced/Installed Item

Work Procedure

Flexible hose (front/rear)

Bleed brake line

Disc brake cylinder assembly (front/rear)

Brake actuator assembly

Bleed brake system

Brake master cylinder sub-assembly

Brake master cylinder reservoir assembly

Brake booster assembly

HINT:

If any work is performed on the brake system or if air in the brake lines is suspected, bleed the air from the brake system.

PROCEDURE

1. BLEED BRAKE LINE

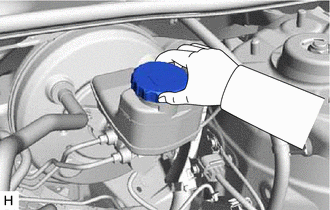

| (a) Remove the brake master cylinder reservoir filler cap assembly. |

|

(b) Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

Brake Fluid:

SAE J1703 or FMVSS No. 116 DOT 3

SAE J1704 or FMVSS No. 116 DOT 4

NOTICE:

- Make sure that there is sufficient brake fluid in the reservoir.

- Do not remove the filter from the brake master cylinder reservoir assembly and be sure to fill the brake master cylinder reservoir assembly with new brake fluid to avoid any potential contamination of the brake system. Contamination, for example by dirt particles or mineral oil, could lead to functional brake problems.

(c) Remove the bleeder plug cap.

(d) Connect a vinyl tube to the bleeder plug.

(e) Depress the brake pedal several times, and then loosen the bleeder plug with the pedal depressed.*1

(f) When fluid stops coming out, tighten the bleeder plug and release the brake pedal.*2

(g) Repeat steps *1 and *2 until all the air in the brake fluid is completely bled out and new brake fluid comes out.

(h) Tighten the bleeder plug completely.

Torque:

8.3 N·m {85 kgf·cm, 73 in·lbf}

(i) Install the bleeder plug cap.

(j) Repeat the above steps to bleed the brake fluid of the brake lines for each wheel.

(k) Inspect for brake fluid leaks.

(l) Inspect the brake fluid level in the reservoir.

Click here .gif)

(m) Install the brake master cylinder reservoir filler cap assembly.

2. BLEED BRAKE SYSTEM

NOTICE:

- To prevent brake fluid from damaging painted surfaces, cover any surrounding parts with a piece of cloth.

- Be sure to clean your hands before bleeding the brake master cylinder sub-assembly to avoid any potential contamination of the brake system. Contamination, for example by dirt particles or mineral oil, could lead to functional brake problems.

| (a) Remove the brake master cylinder reservoir filler cap assembly. |

|

(b) Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

Brake Fluid:

SAE J1703 or FMVSS No. 116 DOT 3

SAE J1704 or FMVSS No. 116 DOT 4

NOTICE:

- Make sure that there is sufficient brake fluid in the reservoir.

- Do not remove the filter from the brake master cylinder reservoir and be sure to fill the brake master cylinder reservoir with new brake fluid to avoid any potential contamination of the brake system. Contamination, for example by dirt particles or mineral oil, could lead to functional brake problems.

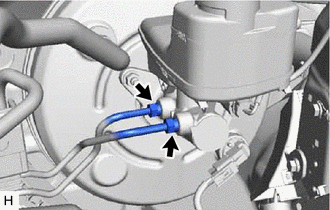

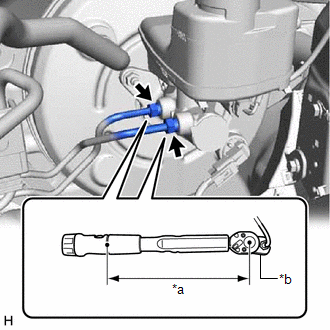

| (c) Using a union nut wrench, disconnect the 2 brake lines from the brake master cylinder sub-assembly. NOTICE:

|

|

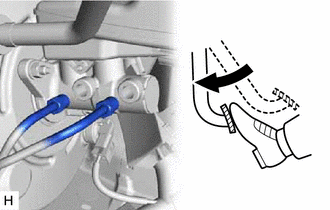

| (d) Slowly depress the brake pedal and hold it.*1 |

|

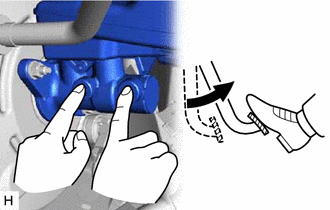

| (e) Cover the 2 outer holes with fingers, and release the brake pedal.*2 |

|

(f) Repeat steps *1 and *2, 3 or 4 times.

| (g) Using a union nut wrench, connect the 2 brake lines to the brake master cylinder sub-assembly. Torque: Specified tightening torque : 19.5 N·m {199 kgf·cm, 14 ft·lbf} NOTICE:

HINT:

|

|

(h) Remove the bleeder plug cap.

(i) Connect a vinyl tube to the bleeder plug.

(j) Depress the brake pedal several times, and then loosen the bleeder plug with the pedal depressed.*1

(k) When fluid stops coming out, tighten the bleeder plug and release the brake pedal.*2

(l) Repeat steps *1 and *2 until all the air in the brake fluid is completely bled out and new brake fluid comes out.

(m) Tighten the bleeder plug completely.

Torque:

8.3 N·m {85 kgf·cm, 73 in·lbf}

(n) Install the bleeder plug cap.

(o) Repeat the above steps to bleed the brake fluid of the brake lines for each wheel.

(p) Inspect for brake fluid leaks.

(q) Inspect the brake fluid level in the reservoir.

Click here .gif)

(r) Install the brake master cylinder reservoir filler cap assembly.