Lexus ES: ACIS Control Circuit

DESCRIPTION

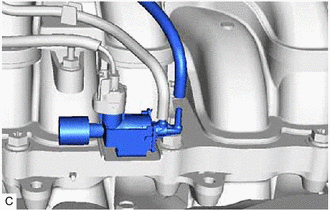

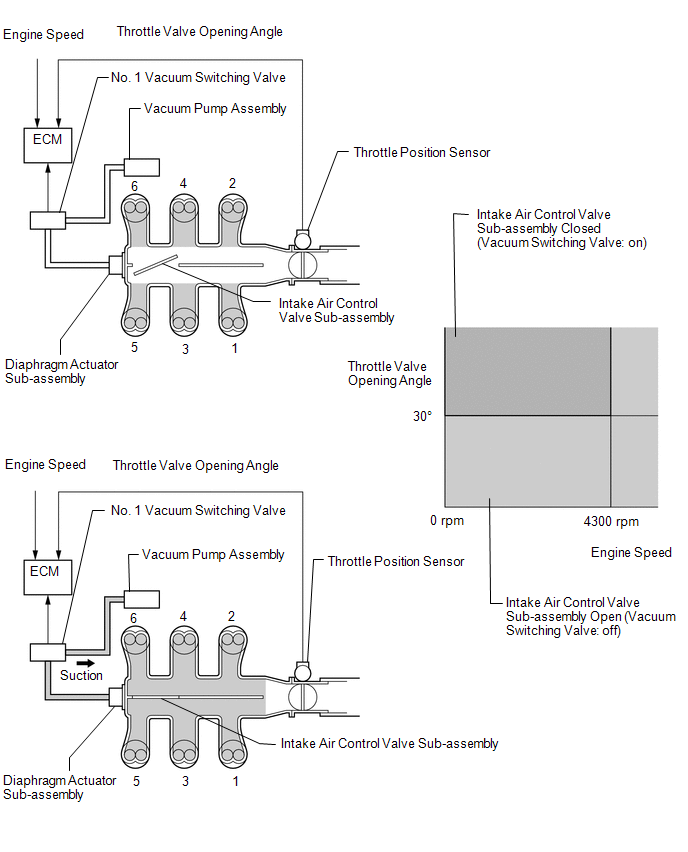

ACIS (Acoustic Control Induction System) controls the opening and closing the intake air control valve sub-assembly built into the intake air surge tank assembly to increase the intake efficiency according to the engine load.

When the engine speed is between 0 and 4300 rpm and the throttle valve opening angle is 30° or more, the ECM activates the No. 1 vacuum switching valve (for intake air control valve sub-assembly) which then applies vacuum from the vacuum pump assembly to the diaphragm actuator sub-assembly and closes the intake air control valve sub-assembly.

When the engine speed and/or throttle valve opening angle are not as specified above, the ECM deactivates the No. 1 vacuum switching valve (for intake air control valve sub-assembly), causing the intake air control valve sub-assembly to open.

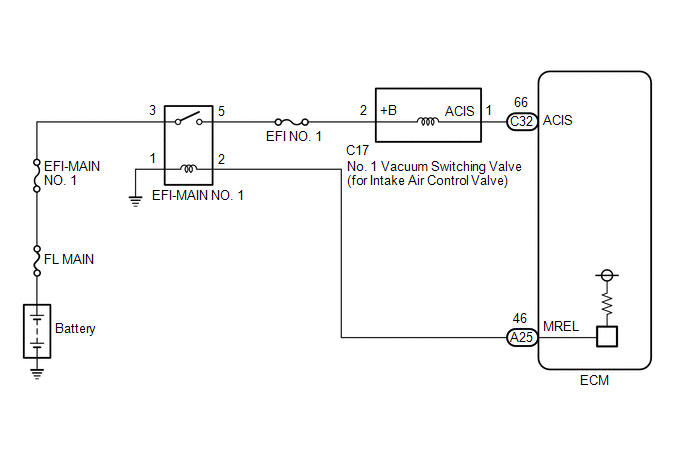

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

| 1. | PERFORM ACTIVE TEST USING TECHSTREAM (ACTIVATE THE VSV FOR INTAKE CONTROL) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Active Test / Activate the VSV for Intake Control.

Powertrain > Engine > Active Test| Tester Display |

|---|

| Activate the VSV for Intake Control |

(e) According to the display on the Techstream, perform the Active Test to operate the No. 1 vacuum switching valve (for intake air control valve sub-assembly) and check for the operating sound of the intake air control valve sub-assembly in the intake air surge tank assembly.

OK:

Operating sounds can be heard.

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

| 2. | INSPECT INTAKE AIR SURGE TANK ASSEMBLY (INTAKE AIR CONTROL VALVE SUB-ASSEMBLY OPERATION) |

(a) Inspect the intake air surge tank assembly (intake air control valve sub-assembly).

Click here .gif)

| NG | .gif) | REPLACE INTAKE AIR SURGE TANK ASSEMBLY |

|

| 3. | INSPECT VACUUM HOSE SUB-ASSEMBLY (NO. 1 VACUUM SWITCHING VALVE (FOR INTAKE AIR CONTROL VALVE SUB-ASSEMBLY) - INTAKE AIR SURGE TANK ASSEMBLY) |

(a) Check the vacuum hose sub-assembly (No. 1 vacuum switching valve (for intake air control valve sub-assembly) - intake air surge tank assembly) for looseness, disconnection and blockage.

OK:

No looseness, disconnection or blockage.

| NG | .gif) | REPAIR OR REPLACE VACUUM HOSE SUB-ASSEMBLY |

|

| 4. | CHECK VACUUM |

| (a) Disconnect the vacuum hose sub-assembly from the No. 1 vacuum switching valve (for intake air control valve sub-assembly). |

|

(b) Start the engine.

(c) Using your finger, confirm that the hose has suction.

| Result | Proceed to |

|---|---|

| Suction applied | A |

| No suction | B |

| B | .gif) | GO TO STEP 9 |

|

| 5. | INSPECT NO. 1 VACUUM SWITCHING VALVE (FOR INTAKE AIR CONTROL VALVE SUB-ASSEMBLY) |

(a) Inspect the No. 1 vacuum switching valve (for intake air control valve sub-assembly).

Click here .gif)

| NG | .gif) | REPLACE NO. 1 VACUUM SWITCHING VALVE (FOR INTAKE AIR CONTROL VALVE SUB-ASSEMBLY) |

|

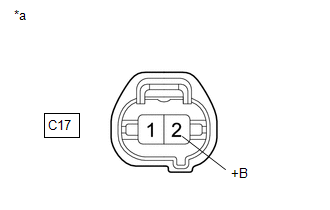

| 6. | CHECK TERMINAL VOLTAGE (POWER SOURCE OF NO. 1 VACUUM SWITCHING VALVE (FOR INTAKE AIR CONTROL VALVE SUB-ASSEMBLY)) |

| (a) Disconnect the No. 1 vacuum switching valve (for intake air control valve sub-assembly) connector. |

|

(b) Turn the engine switch on (IG).

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| C17-2 (+B) - Body ground | Engine switch on (IG) | 11 to 14 V |

| NG | .gif) | GO TO STEP 8 |

|

| 7. | CHECK HARNESS AND CONNECTOR (NO. 1 VACUUM SWITCHING VALVE (FOR INTAKE AIR CONTROL VALVE SUB-ASSEMBLY) - ECM) |

(a) Disconnect the No. 1 vacuum switching valve (for intake air control valve sub-assembly) connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| C17-1 (ACIS) - C32-66 (ACIS) | Always | Below 1 Ω |

| C17-1 (ACIS) or C32-66 (ACIS) - Body ground and other terminals | Always | 10 kΩ or higher |

| OK | .gif) | REPLACE ECM |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 8. | CHECK HARNESS AND CONNECTOR (EFI-MAIN NO. 1 RELAY - NO. 1 VACUUM SWITCHING VALVE (FOR INTAKE AIR CONTROL VALVE SUB-ASSEMBLY)) |

(a) Remove the EFI-MAIN NO. 1 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Disconnect the No. 1 vacuum switching valve (for intake air control valve sub-assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 5 (EFI-MAIN NO. 1 relay) - C17-2 (+B) | Always | Below 1 Ω |

| 5 (EFI-MAIN NO. 1 relay) or C17-2 (+B) - Body ground and other terminals | Always | 10 kΩ or higher |

| OK | .gif) | GO TO ECM POWER SOURCE CIRCUIT |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 9. | INSPECT VACUUM PUMP ASSEMBLY |

(a) Inspect the vacuum pump assembly.

-

for TMC Made: Click here

.gif)

-

for TMMK Made: Click here

.gif)

| OK | .gif) | REPAIR OR REPLACE VACUUM HOSE SUB-ASSEMBLY (NO. 1 VACUUM SWITCHING VALVE (FOR INTAKE AIR CONTROL VALVE SUB-ASSEMBLY) - VACUUM PUMP ASSEMBLY) |

| NG | .gif) | REPLACE VACUUM PUMP ASSEMBLY |

.gif)