Lexus ES: Wiper Motor Power Source Circuit

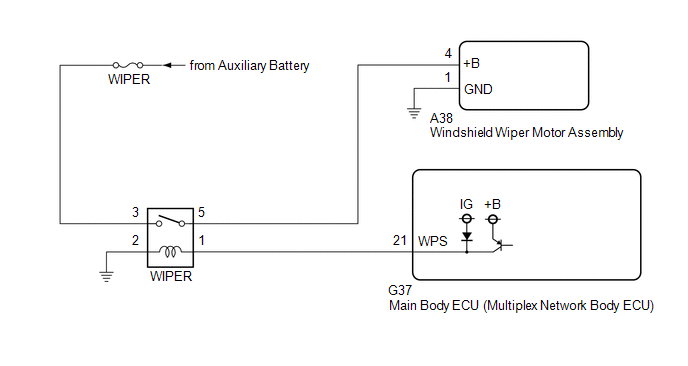

DESCRIPTION

This circuit is the power source circuit for the windshield wiper motor assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses of circuits related to this system before performing the following procedure.

-

Before replacing the main body ECU (multiplex network body ECU), refer to Registration.

Click here

.gif)

.gif)

PROCEDURE

| 1. | READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Wiper / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Wiper > Data List| Tester Display | Measurement Item | Range | Normal Condition | Diagnostic Note |

|---|---|---|---|---|

| Motor Power Supply Voltage | Front wiper motor assembly supply voltage status | Min.: 0 V Max.: 63 V | Almost the same as actual windshield wiper motor assembly voltage | - |

| Tester Display |

|---|

| Motor Power Supply Voltage |

OK:

The Techstream display is normal.

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

| 2. | CHECK HARNESS AND CONNECTOR (WINDSHIELD WIPER MOTOR ASSEMBLY - BODY GROUND) |

(a) Disconnect the A38 windshield wiper motor assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A38-1 (GND) - Body ground | Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. | CHECK HARNESS AND CONNECTOR (POWER SOURCE - WINDSHIELD WIPER MOTOR ASSEMBLY) |

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A38-4 (+B) - Body ground | Power switch on (IG) | 11 to 14 V |

| Less than approximately 60 seconds after power switch turned off | 11 to 14 V | |

| Approximately 60 seconds after power switch turned off | Below 1 V |

| OK | .gif) | REPLACE WINDSHIELD WIPER MOTOR ASSEMBLY |

|

| 4. | INSPECT WIPER RELAY |

(a) Inspect the WIPER relay.

Click here .gif)

| NG | .gif) | REPLACE WIPER RELAY |

|

| 5. | CHECK HARNESS AND CONNECTOR (POWER SOURCE - WIPER RELAY) |

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 3 (WIPER relay) - Body ground | Always | 11 to 14 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 6. | CHECK HARNESS AND CONNECTOR (WIPER RELAY - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 2 (WIPER relay) - Body ground | Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 7. | CHECK HARNESS AND CONNECTOR (WIPER RELAY - WINDSHIELD WIPER MOTOR ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 5 (WIPER relay) - A38-4 (+B) | Always | Below 1 Ω |

| 5 (WIPER relay) or A38-4 (+B) - Body ground | Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 8. | CHECK HARNESS AND CONNECTOR (WIPER RELAY - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the G37 main body ECU (multiplex network body ECU) connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| 1 (WIPER relay) - G37-21 (WPS) | Always | Below 1 Ω |

| 1 (WIPER relay) or G37-21 (WPS) - Body ground | Always | 10 kΩ or higher |

| OK | .gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)