Lexus ES: Stop Lamp Relay Actuator Stuck On (C13807E)

DESCRIPTION

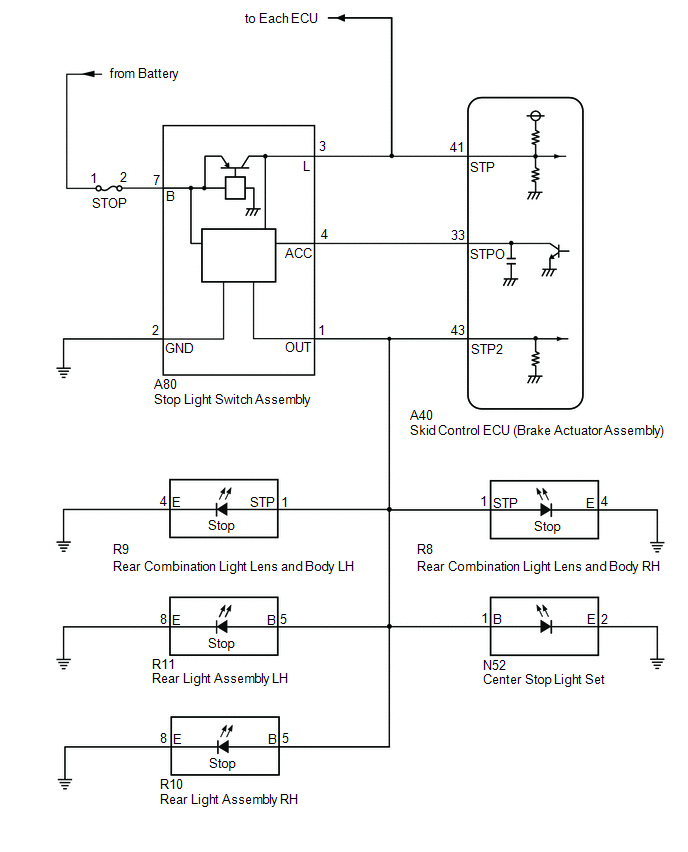

When any of the following conditions are met, the skid control ECU (brake actuator assembly) sets the drive output (STPO) ON which operates the stop light control relay (stop light switch assembly) and turns on the stop lights.

- Pre-collision brake is operating.

- The dynamic radar cruise control system is operating and is applying the brakes.

- Secondary collision brake is operating.

- Brake hold is operating.

- The parking brake is engaged while the vehicle is being driven.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| C13807E | Stop Lamp Relay Actuator Stuck On | When the voltage at the +BS terminal is between 10 V or more and the stop light control relay (stop light switch assembly) drive output (STPO) is off, the signal at the STP2 terminal is different from the input signal at the STP terminal for 5 seconds or more. |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

-

After replacing the skid control ECU (brake actuator assembly), perform acceleration sensor zero point calibration and store system information memorization.

Click here

.gif)

HINT:

When DTC P057111, P057112 and/or P057113 are output together with DTC C13807E, inspect and repair the trouble areas indicated by DTC P057111, P057112 and/or P057113 first.

P057111: Click here .gif)

P057112: Click here .gif)

P057113: Click here .gif)

PROCEDURE

| 1. | CHECK STOP LIGHT ILLUMINATION STATUS |

(a) With the brake pedal released, check the illumination status of the brake lights.

| Result | Proceed to |

|---|---|

| The stop lights are illuminated. | A |

| The stop lights are not illuminated. | B |

| B |  | GO TO STEP 7 |

|

| 2. | CHECK HARNESS AND CONNECTOR (STOP LIGHT CONTROL RELAY CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

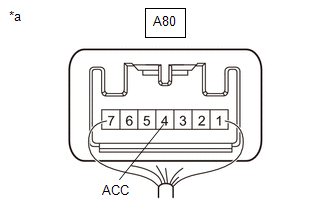

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A80-4 (ACC) - Body ground | Always | 11 to 14 V |

| NG |  | GO TO STEP 5 |

|

| 3. | CHECK STOP LIGHT ILLUMINATION STATUS |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A80 stop light switch assembly connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Check the illumination status of the brake lights.

| Result | Proceed to |

|---|---|

| The stop lights are illuminated. | A |

| The stop lights are not illuminated. | B |

| B |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

|

| 4. | CHECK STOP LIGHT ILLUMINATION STATUS |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A80 stop light switch assembly connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Check the illumination status of the brake lights.

| Result | Proceed to |

|---|---|

| The stop lights are illuminated. | A |

| The stop lights are not illuminated. | B |

| A |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (STOP LIGHT CIRCUIT) |

| B |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

| 5. | CHECK HARNESS AND CONNECTOR (STOP LIGHT CONTROL RELAY CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A80-4 (ACC) - Body ground | Always | 11 to 14 V |

| OK |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

|

| 6. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A80 stop light switch assembly connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A80-4 (ACC) or A40-33 (STPO) - Body ground and other terminals | Always | 10 kΩ or higher |

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 7. | CHECK STOP LIGHT OPERATION |

(a) Check that the stop lights come on when the brake pedal is depressed.

OK:

The stop lights illuminate.

| NG |  | GO TO STEP 9 |

|

| 8. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SIGNAL INPUT CIRCUIT) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

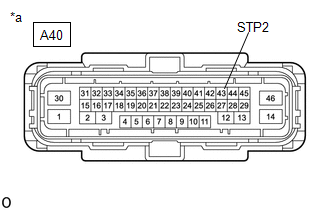

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A40-43 (STP2) - Body ground | Brake pedal depressed | 11 to 14 V |

| OK |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 9. | CHECK STOP LIGHT OPERATION |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Check that the stop lights come on when the brake pedal is depressed.

OK:

The stop lights illuminate.

| OK |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

|

| 10. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR COMBINATION LIGHT LENS AND BODY LH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the R9 rear combination light lens and body LH connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

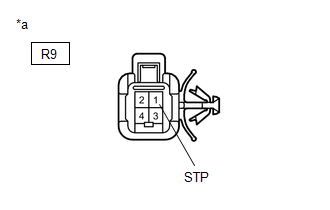

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R9-1 (STP) - Body ground | Brake pedal depressed | 11 to 14 V |

| OK |  | REPLACE REAR COMBINATION LIGHT LENS AND BODY LH |

|

| 11. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR COMBINATION LIGHT LENS AND BODY RH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the R9 rear combination light lens and body LH connector.

(d) Disconnect the R8 rear combination light lens and body RH connector.

(e) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

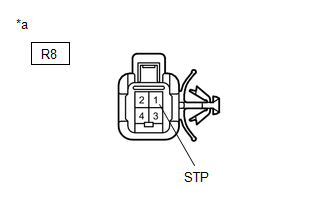

(f) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R8-1 (STP) - Body ground | Brake pedal depressed | 11 to 14 V |

| OK |  | REPLACE REAR COMBINATION LIGHT LENS AND BODY RH |

|

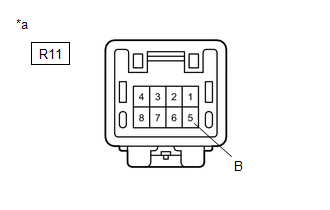

| 12. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR LIGHT ASSEMBLY LH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the R9 rear combination light lens and body LH connector.

(d) Disconnect the R8 rear combination light lens and body RH connector.

(e) Disconnect the R11 rear light assembly LH connector.

(f) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(g) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R11-5 (B) - Body ground | Brake pedal depressed | 11 to 14 V |

| OK |  | REPLACE REAR LIGHT ASSEMBLY LH |

|

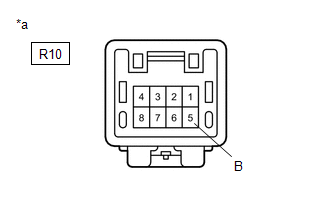

| 13. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR LIGHT ASSEMBLY RH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the R9 rear combination light lens and body LH connector.

(d) Disconnect the R8 rear combination light lens and body RH connector.

(e) Disconnect the R11 rear light assembly LH connector.

(f) Disconnect the R10 rear light assembly RH connector.

(g) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(h) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| R10-5 (B) - Body ground | Brake pedal depressed | 11 to 14 V |

| OK |  | REPLACE REAR LIGHT ASSEMBLY RH |

|

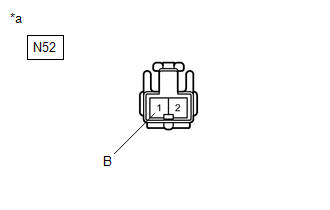

| 14. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - CENTER STOP LIGHT SET) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the R9 rear combination light lens and body LH connector.

(d) Disconnect the R8 rear combination light lens and body RH connector.

(e) Disconnect the R11 rear light assembly LH connector.

(f) Disconnect the R10 rear light assembly RH connector.

(g) Disconnect the N52 center stop light set connector.

(h) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(i) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| N52-1 (B) - Body ground | Brake pedal depressed | 11 to 14 V |

| OK |  | REPLACE CENTER STOP LIGHT SET |

|

| 15. | CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - REAR COMBINATION LIGHT LENS AND BODY LH) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A40 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A80 stop light switch assembly connector.

(d) Disconnect the R9 rear combination light lens and body LH connector.

(e) Disconnect the R8 rear rear combination light lens and body RH connector.

(f) Disconnect the R11 rear light assembly LH connector.

(g) Disconnect the R10 rear light assembly RH connector.

(h) Disconnect the N52 center stop light set connector.

(i) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(j) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

| Tester Connection | Condition | Specified Condition |

|---|---|---|

| A80-1 (OUT) - R9-1 (STP) | Always | Below 1 Ω |

| A80-1 (OUT) or R9-1 (STP) - Body ground | Always | 10 kΩ or higher |

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |