Lexus ES: Replacement

REPLACEMENT

PROCEDURE

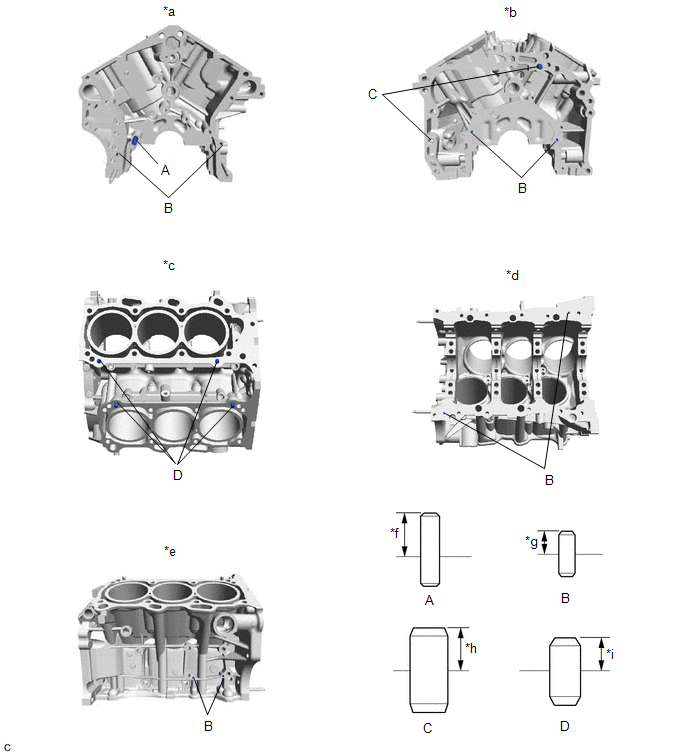

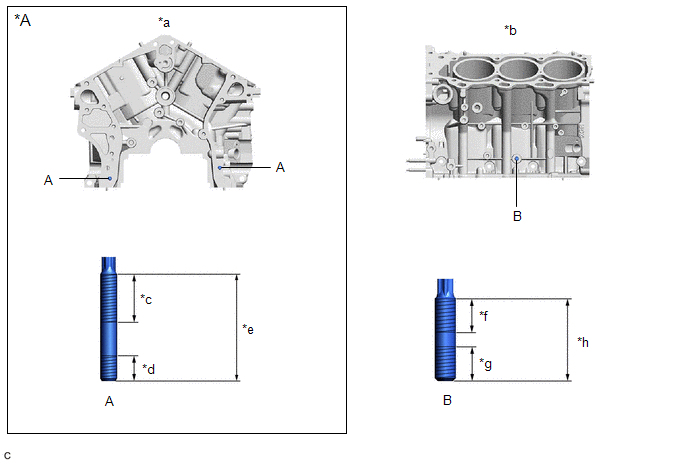

1. REPLACE STRAIGHT PIN

NOTICE:

If a straight pin is deformed, replace it.

(a) Using a plastic hammer, tap in new straight pins to the cylinder block sub-assembly.

| *a | Front Side | *b | Rear Side |

| *c | Top Side | *d | Bottom Side |

| *e | RH Side | *f | 23 mm (0.906 in.) |

| *g | 6 mm (0.236 in.) | *h | 11 mm (0.433 in.) |

| *i | 9 mm (0.354 in.) | - | - |

Standard Protrusion Height:

| Item | Specified Condition |

|---|---|

| Pin (A) | 23 mm (0.906 in.) |

| Pin (B) | 6 mm (0.236 in.) |

| Pin (C) | 11 mm (0.433 in.) |

| Pin (D) | 9 mm (0.354 in.) |

2. REPLACE STUD BOLT

NOTICE:

If a stud bolt is deformed or its threads are damaged, replace it.

(a) Using E8 and E10 "TORX" socket wrenches, install the stud bolts to the cylinder block sub-assembly.

| *A | w/ Stud Bolt | - | - |

| *a | Front Side | *b | LH Side |

| *c | 24 mm (0.9449 in.) | *d | 12 mm (0.4724 in.) |

| *e | 52 mm (2.05 in.) | *f | 23 mm (0.906 in.) |

| *g | 15 mm (0.591 in.) | *h | 40 mm (1.57 in.) |

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

3. REPLACE CONNECTING ROD SMALL END BUSH

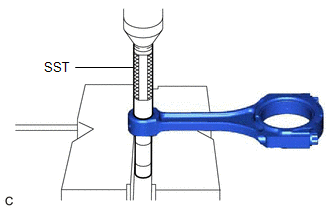

| (a) Using SST and a press, press out the connecting rod small end bush. SST: 09222-30010 |

|

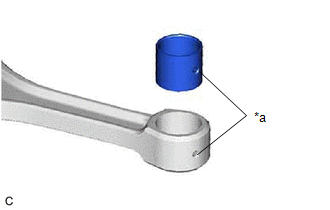

| (b) Align the oil hole of a new connecting rod small end bush with the oil hole of the connecting rod. |

|

| (c) Using SST and a press, push in the connecting rod small end bush. SST: 09222-30010 |

|

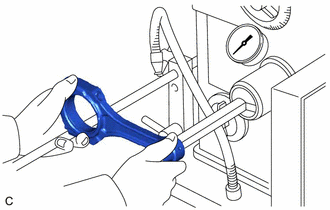

| (d) Using a pin hole grinder, hone the connecting rod small end bush to obtain the standard oil clearance between the connecting rod small end bush and piston pin. Standard Oil Clearance: 0.005 to 0.011 mm (0.000197 to 0.000433 in.) |

|

(e) Coat the piston pin with engine oil, and push it into the connecting rod with your thumb.

HINT:

Check that the piston pin fits at a normal room temperature.