Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during power window regulator motor assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced (for HV Model)| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function When Necessary Procedures are not Performed | Link |

|---|---|---|---|

|

*: When performing learning using the Techstream.

Click here | |||

| Disconnect cable from negative auxiliary battery terminal | Perform steering sensor zero point calibration | Lane Control System | |

| Pre-collision System | |||

| Parking Support Brake System* | |||

| Lighting System | |||

| Memorize steering angle neutral point | Parking Assist Monitor System | | |

| Panoramic View Monitor System | | ||

| Initialize power trunk lid system | Power Trunk Lid System | | |

| Initialize power window control system |

| |

NOTICE:

- After the power switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the power switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) auxiliary battery terminal. (for Audio and Visual System)

- After the power switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the power switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) auxiliary battery terminal. (for Navigation System)

| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function When Necessary Procedures are not Performed | Link |

|---|---|---|---|

|

*: When performing learning using the Techstream.

Click here | |||

| Disconnect cable from negative battery terminal | Perform steering sensor zero point calibration | Lane Control System | |

| Pre-collision System | |||

| Parking Support Brake System* | |||

| Lighting System | |||

| Memorize steering angle neutral point | Parking Assist Monitor System | | |

| Panoramic View Monitor System | | ||

| Initialize power trunk lid system | Power Trunk Lid System | | |

| Initialize power window control system |

| |

NOTICE:

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System)

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the engine switch (for Gasoline Model) or power switch (for HV Model) off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

2. DISCONNECT CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL

for 2GR-FKS:

Click here .gif)

for A25A-FXS:

Click here .gif)

3. REMOVE REAR POWER WINDOW REGULATOR SWITCH ASSEMBLY WITH REAR DOOR UPPER ARMREST BASE PANEL

Click here .gif)

4. REMOVE REAR DOOR TRIM UPPER PAD

Click here .gif)

5. REMOVE COURTESY LIGHT ASSEMBLY

Click here .gif)

6. REMOVE REAR DOOR TRIM BOARD SUB-ASSEMBLY

Click here .gif)

7. REMOVE REAR SIDE CURTAIN ASSEMBLY (w/ Rear Door Sunshade)

Click here .gif)

8. REMOVE REAR DOOR SERVICE HOLE COVER

Click here .gif)

9. REMOVE REAR DOOR NO. 2 SERVICE HOLE COVER

Click here .gif)

10. REMOVE REAR DOOR NO. 2 VENT SEAL

Click here .gif)

11. REMOVE REAR DOOR PANEL PROTECTOR

Click here .gif)

12. REMOVE REAR DOOR GLASS RUN

Click here .gif)

13. DISCONNECT REAR DOOR WEATHERSTRIP

Click here .gif)

14. REMOVE REAR DOOR WINDOW DIVISION BAR SUB-ASSEMBLY

Click here .gif)

15. REMOVE REAR DOOR QUARTER WINDOW GLASS SUB-ASSEMBLY

Click here .gif)

16. REMOVE REAR DOOR GLASS SUB-ASSEMBLY

Click here .gif)

17. REMOVE REAR DOOR WINDOW REGULATOR ASSEMBLY

Click here .gif)

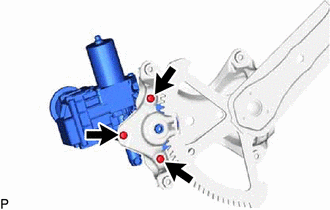

18. REMOVE POWER WINDOW REGULATOR MOTOR ASSEMBLY

| (a) Using a T25 "TORX" socket wrench, remove the 3 screws and power window regulator motor assembly. |

|