Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during mass air flow meter sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

| Replacement of mass air flow meter sub-assembly | Inspection after repair | -

Poor idle, etc.

-

Engine start function, etc.

| .gif) |

PROCEDURE

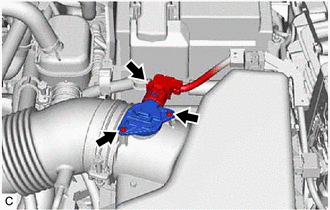

1. REMOVE MASS AIR FLOW METER SUB-ASSEMBLY

| (a) Disconnect the mass air flow meter sub-assembly connector. | |

(b) Remove the 2 screws and mass air flow meter sub-assembly from the air cleaner cap sub-assembly.

NOTICE:

If the mass air flow meter sub-assembly has been struck or dropped, replace it.

READ NEXT:

INSPECTION PROCEDURE 1. INSPECT MASS AIR FLOW METER SUB-ASSEMBLY (a) Perform a visual check for any foreign matter on the intake air temperature sensor (thermistor) of the mass air flow meter sub-a

INSTALLATION PROCEDURE 1. INSTALL MASS AIR FLOW METER SUB-ASSEMBLY HINT: Perform "Inspection After Repair" after replacing the mass air flow meter sub-assembly. Click here (a) Install the mass air f

On-vehicle InspectionON-VEHICLE INSPECTION PROCEDURE 1. INSPECT MAIN RELAY (EFI-MAIN NO. 1) (a) Measure the resistance according to the value(s) in the table below. Standard Resistance: Tester

SEE MORE:

COMPONENTS ILLUSTRATION *1 REAR BUMPER ASSEMBLY *2 REAR COMBINATION LIGHT COVER LH *3 REAR COMBINATION LIGHT COVER RH - - ILLUSTRATION *A w/ Hands Free Power Trunk Lid - - *1 KICK DOOR CONTROL SENSOR WITH BRACKET - - ILLUSTRATION *A w/ Parking Supp

COMPONENTS ILLUSTRATION *A w/o Panoramic View Monitor System *B w/ Panoramic View Monitor System *1 OUTER MIRROR *2 OUTER MIRROR COVER ASSEMBLY *3 OUTER MIRROR LOWER COVER *4 OUTER MIRROR UPPER COVER *5 SIDE TELEVISION CAMERA ASSEMBLY *6 VISOR COVER ASSEMBLY

© 2016-2026 Copyright www.lexguide.net

.gif)