Lexus ES: Removal

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during camshaft removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link |

|---|---|---|---|

| Battery terminal is disconnected/reconnected | Perform steering sensor zero point calibration | Lane Control System | |

| Pre-collision System | |||

| Parking Support Brake System*1 | |||

| Lighting System | |||

| Memorize steering angle neutral point | Parking Assist Monitor System | | |

| Panoramic View Monitor System | | ||

| Initialize power trunk lid system | Power Trunk Lid System | | |

| Replacement of ECM | Vehicle Identification Number (VIN) registration | MIL comes on | |

| ECU communication ID registration (Immobiliser system) | Engine start function | | |

| Inspection after repair |

| |

| Replacement of automatic transaxle assembly |

|

| for Initialization: for Registration: |

| Replacement of ECM (If transaxle compensation code read from ECM) |

| ||

| Replacement of ECM (If transaxle compensation code not read from ECM) |

| ||

| Replacement of ECM | Code registration (Smart access system with push-button start (for Start Function, Gasoline Model) |

| |

| Replacement of automatic transaxle fluid | ATF thermal degradation estimate reset | The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly | |

| Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) | Rear television camera assembly optical axis adjustment (Back camera position setting) | Parking assist monitor system | for Initialization: for Calibration: |

| Perform headlight ECU sub-assembly LH initialization | Lighting system | | |

| Front wheel alignment adjustment |

|

| |

| Front television camera view adjustment | Panoramic View Monitor System | for Initialization for Calibration |

| Replacement of front bumper assembly |

|

| |

-

*1: When performing learning using the Techstream.

Click here

.gif)

- *2: Not necessary when ECM replaced with new one

NOTICE:

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System)

- After the engine switch is turned off, the radio receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

PROCEDURE

1. INSTALL ENGINE ASSEMBLY TO ENGINE STAND

Click here .gif)

2. REMOVE ENGINE HANGERS

Click here .gif)

3. REMOVE THROTTLE BODY WITH MOTOR ASSEMBLY

Click here .gif)

4. DISCONNECT VENTILATION HOSE

Click here .gif)

5. DISCONNECT PURGE VALVE (PURGE VSV)

Click here .gif)

6. REMOVE NO. 2 SURGE TANK STAY

Click here .gif)

7. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

Click here .gif)

8. REMOVE AIR SURGE TANK TO INTAKE MANIFOLD GASKET

Click here .gif)

9. REMOVE IGNITION COIL ASSEMBLY

Click here .gif)

10. REMOVE VACUUM PUMP ASSEMBLY

-

for TMMK Made:

Click here

.gif)

-

for TMC Made:

Click here

.gif)

11. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

Click here .gif)

12. REMOVE WIRE HARNESS CLAMP BRACKET

Click here .gif)

13. REMOVE WATER FILLER BRACKET

Click here .gif)

14. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 1)

Click here .gif)

15. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 1)

Click here .gif)

16. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 2)

Click here .gif)

17. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 2)

Click here .gif)

18. REMOVE VVT SENSOR (for Intake Side of Bank 1)

Click here .gif)

19. REMOVE VVT SENSOR (for Exhaust Side of Bank 1)

Click here .gif)

20. REMOVE VVT SENSOR (for Intake Side of Bank 2)

Click here .gif)

21. REMOVE VVT SENSOR (for Exhaust Side of Bank 2)

Click here .gif)

22. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

Click here .gif)

23. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY LH

Click here .gif)

24. REMOVE SPARK PLUG TUBE GASKET

Click here .gif)

25. REMOVE TIMING CHAIN COVER PLATE

Click here .gif)

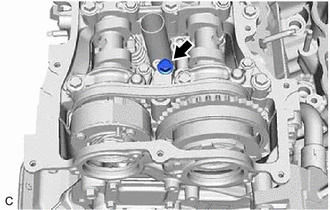

26. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

| (a) Turn the crankshaft clockwise to align the timing mark (cutout) on the crankshaft pulley with the "0" timing mark on the timing chain cover assembly. |

|

| (b) Check that the timing marks of the camshaft timing gear assemblies are aligned with the timing marks of the camshaft bearing caps as shown in the illustration. HINT: If the marks are not aligned, turn the crankshaft again to align the marks. |

|

(c) Place paint marks on the timing marks and sprockets of each camshaft timing gear assembly and on the links of the chain sub-assembly.

HINT:

Be sure to place the paint marks on 2 links of the chain sub-assembly and on the sprockets of the camshaft timing gear assemblies at the locations of the timing marks of the camshaft timing gear assemblies.

27. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

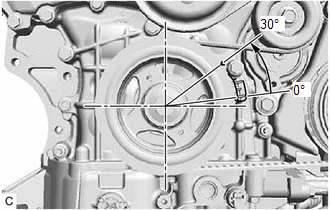

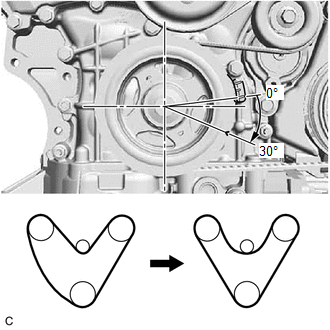

| (a) Turn the crankshaft approximately 30° counterclockwise so that there is some slack in the chain sub-assembly. HINT: This prevents the valves and pistons from interfering with each other. |

|

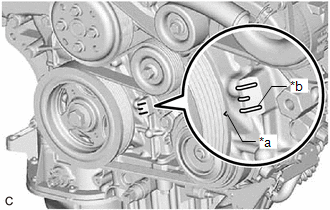

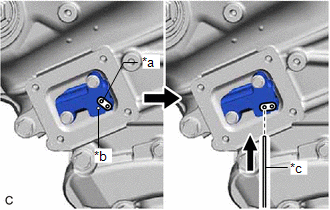

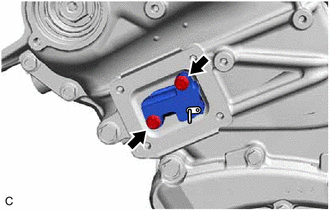

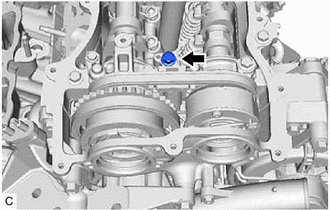

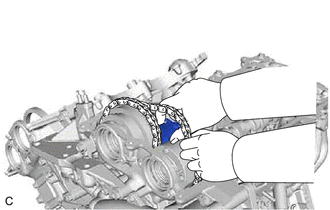

| (b) Align the hole in the lever of the No. 1 chain tensioner assembly with the hole in the tensioner body as shown in the illustration, and then insert a pin with a diameter of 1.0 mm (0.0394 in.) into the hole. NOTICE: Check that the pin is locked. |

|

| (c) Turn the crankshaft clockwise to align the timing mark (cutout) on the crankshaft pulley with the "0" timing mark on the timing chain cover assembly. |

|

| (d) Remove the 2 bolts and No. 1 chain tensioner assembly from the cylinder head sub-assembly. NOTICE: Do not drop the No. 1 chain tensioner assembly or bolts into the timing chain cover assembly. |

|

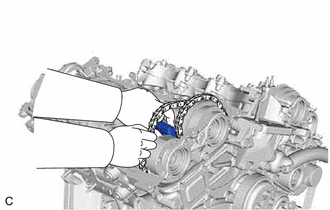

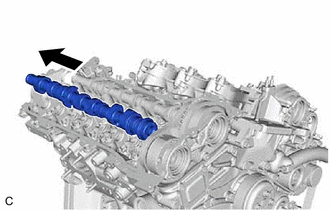

28. DISCONNECT CHAIN SUB-ASSEMBLY (for Bank 1)

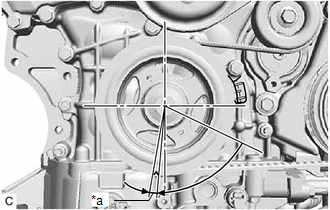

| (a) Turn the crankshaft clockwise until it is in the position shown in the illustration so that there is some slack in the chain sub-assembly between the banks. CAUTION: As the camshafts may turn suddenly, do not touch the camshafts or camshaft timing gears. HINT: When turning the crankshaft, engine oil may spray out of the oil holes. |

|

| (b) Turn the crankshaft clockwise until it is in the position shown in the illustration so that the chain sub-assembly can be removed easily. HINT: When turning the crankshaft, engine oil may spray out of the oil holes. |

|

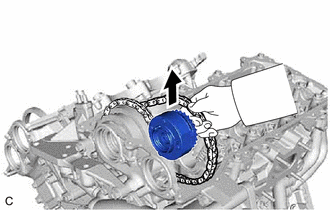

| (c) Remove the chain sub-assembly from the sprocket of the camshaft timing gear assembly and set it on the camshaft timing gear assembly. CAUTION: As the camshaft may turn suddenly and pinch your fingers when the chain sub-assembly is removed, pinch the chain sub-assembly and lift it upward to remove it from the sprocket. |

|

29. SEPARATE NO. 2 CHAIN TENSIONER ASSEMBLY

| (a) Remove the bolt to separate the No. 2 chain tensioner assembly from the camshaft housing sub-assembly. |

|

30. REMOVE CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 1)

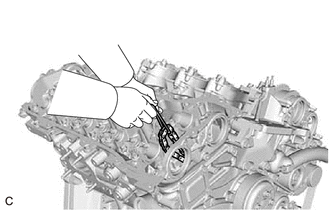

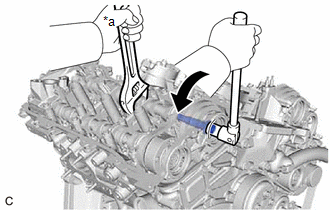

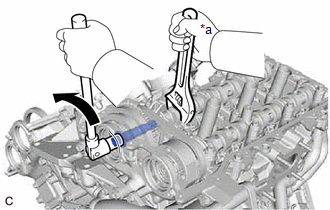

(a) Use a wrench to hold the hexagonal portion of the camshaft and remove the camshaft timing gear bolt from the camshaft timing gear assembly.

| *a | Hold |

.png) | Turn |

NOTICE:

- Be careful not to damage the camshaft, camshaft housing sub-assembly or spark plug tube with the wrench.

- If the camshaft timing gear bolt has been struck or dropped, replace it.

31. REMOVE CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 1)

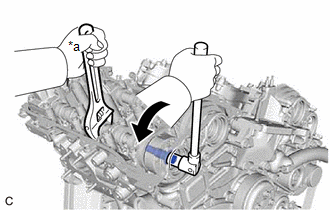

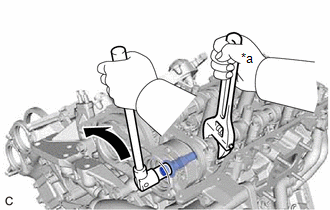

(a) Use a wrench to hold the hexagonal portion of the No. 2 camshaft and remove the camshaft timing gear bolt from the camshaft timing exhaust gear assembly.

NOTICE:

- Be careful not to damage the No. 2 camshaft, camshaft housing sub-assembly or spark plug tube with the wrench.

- If the camshaft timing gear bolt has been struck or dropped, replace it.

| *a | Hold |

.png) | Turn |

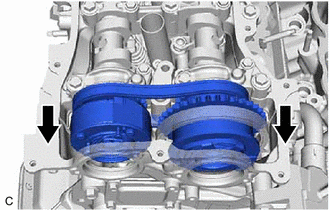

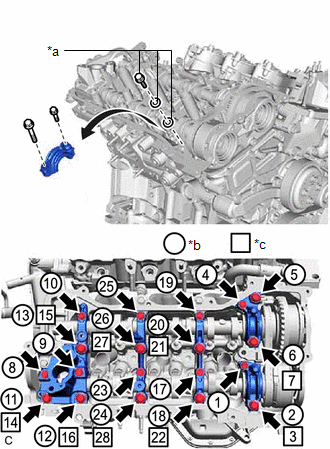

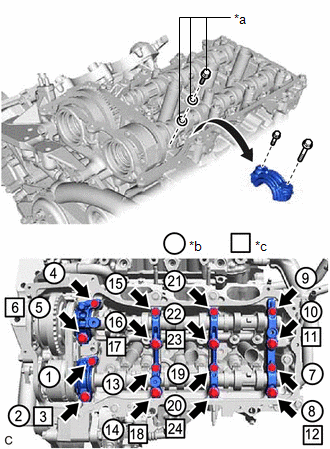

32. REMOVE CAMSHAFT BEARING CAP (for Bank 1)

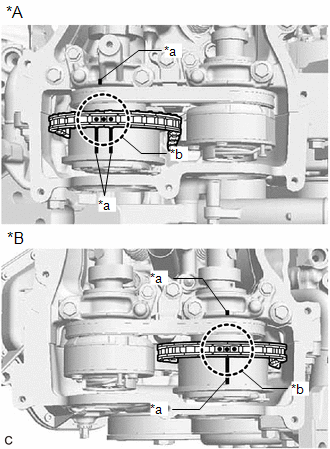

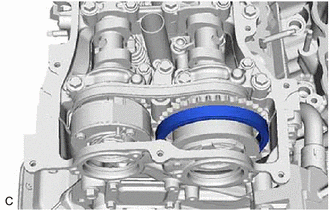

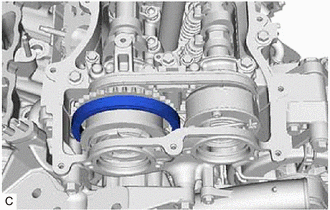

| (a) Slide the camshaft timing gear assembly and camshaft timing exhaust gear assembly as shown in the illustration. |

|

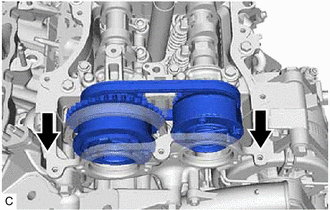

| (b) Remove the bolts and camshaft bearing caps in the order shown in the illustration. Immediately after removing a camshaft bearing cap, install replacement bolts and washers in the order shown in the illustration. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE:

HINT:

|

|

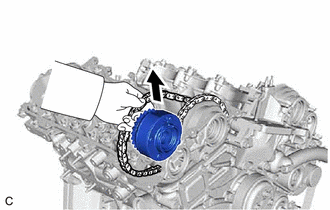

33. REMOVE NO. 2 CAMSHAFT

| (a) While lifting up the camshaft timing exhaust gear assembly, remove the No. 2 chain tensioner assembly. |

|

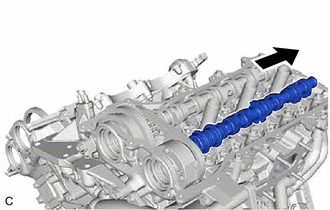

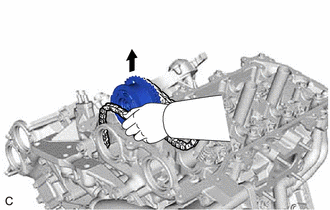

(b) Lift up the rear of the No. 2 camshaft so that it is at an angle.

| (c) Pull the No. 2 camshaft as shown in the illustration to remove it from the camshaft timing exhaust gear assembly. |

|

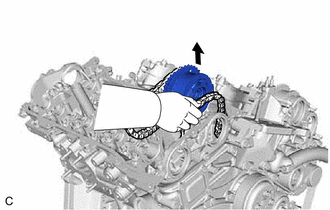

34. REMOVE CAMSHAFT

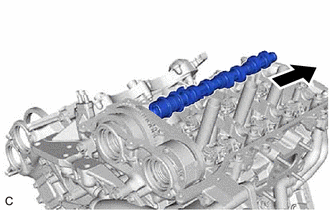

(a) Lift up the rear of the camshaft so that it is at an angle.

| (b) Pull the camshaft as shown in the illustration to remove it from the camshaft timing gear assembly. |

|

35. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY (for Bank 1)

| (a) Remove the camshaft timing exhaust gear assembly. |

|

36. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY (for Bank 1)

| (a) Remove the camshaft timing gear assembly and No. 2 chain sub-assembly. NOTICE: Do not drop the chain sub-assembly into the gap between the engine and timing chain cover assembly. |

|

| (b) Suspend the chain sub-assembly with a string or equivalent. |

|

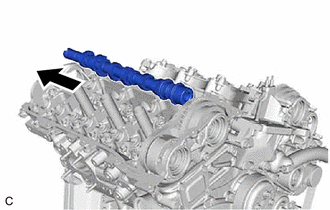

37. DISCONNECT CHAIN SUB-ASSEMBLY (for Bank 2)

| (a) Turn the crankshaft counterclockwise to align the timing mark (cutout) on the crankshaft pulley with the "0" timing mark on the timing chain cover assembly. |

|

| (b) Remove the chain sub-assembly from the sprocket of the camshaft timing gear assembly and set it on the camshaft timing gear assembly. CAUTION: As the camshaft may turn suddenly and pinch your fingers when the chain sub-assembly is removed, pinch the chain sub-assembly and lift it upward to remove it from the sprocket. |

|

38. SEPARATE NO. 3 CHAIN TENSIONER ASSEMBLY

| (a) Remove the bolt to separate the No. 3 chain tensioner assembly from the camshaft housing sub-assembly LH. |

|

39. REMOVE CAMSHAFT TIMING GEAR BOLT (for Intake Side of Bank 2)

(a) Use a wrench to hold the hexagonal portion of the No. 3 camshaft sub-assembly and remove the camshaft timing gear bolt from the camshaft timing gear assembly.

| *a | Hold |

.png) | Turn |

NOTICE:

- Be careful not to damage the No. 3 camshaft sub-assembly, camshaft housing sub-assembly LH or spark plug tube with the wrench.

- If the camshaft timing gear bolt has been struck or dropped, replace it.

40. REMOVE CAMSHAFT TIMING GEAR BOLT (for Exhaust Side of Bank 2)

(a) Use a wrench to hold the hexagonal portion of the No. 4 camshaft sub-assembly and remove the camshaft timing gear bolt from the camshaft timing exhaust gear assembly.

| *a | Hold |

.png) | Turn |

NOTICE:

- Be careful not to damage the No. 4 camshaft sub-assembly, camshaft housing sub-assembly LH or spark plug tube with the wrench.

- If the camshaft timing gear bolt has been struck or dropped, replace it.

41. REMOVE CAMSHAFT BEARING CAP (for Bank 2)

| (a) Slide the camshaft timing gear assembly and camshaft timing exhaust gear assembly as shown in the illustration. |

|

| (b) Remove the bolts and camshaft bearing caps in the order shown in the illustration. Immediately after removing a camshaft bearing cap, install replacement bolts and washers in the order shown in the illustration. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE:

HINT:

|

|

42. REMOVE NO. 4 CAMSHAFT SUB-ASSEMBLY

| (a) While lifting up the camshaft timing exhaust gear assembly, remove the No. 3 chain tensioner assembly. |

|

(b) Lift up the rear of the No. 4 camshaft sub-assembly so that it is at an angle.

| (c) Pull the No. 4 camshaft sub-assembly as shown in the illustration to remove it from the camshaft timing exhaust gear assembly. |

|

43. REMOVE NO. 3 CAMSHAFT SUB-ASSEMBLY

(a) Lift up the rear of the No. 3 camshaft sub-assembly so that it is at an angle.

| (b) Pull the No. 3 camshaft sub-assembly as shown in the illustration to remove it from the camshaft timing gear assembly. |

|

44. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY (for Bank 2)

| (a) Remove the camshaft timing exhaust gear assembly. |

|

45. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY (for Bank 2)

| (a) Remove the camshaft timing gear assembly and No. 2 chain sub-assembly. NOTICE: Do not drop the chain sub-assembly into the gap between the engine and timing chain cover assembly. |

|

| (b) Suspend the chain sub-assembly with a string or equivalent. |

|