Lexus ES: Reassembly

REASSEMBLY

PROCEDURE

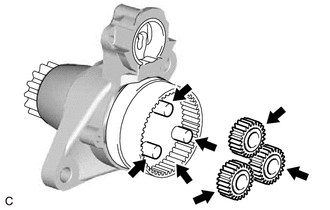

1. INSTALL PLANETARY GEAR

(a) Apply high-temperature grease to the 3 planetary gears, 3 planetary gear shafts and repair service starter kit.

.png) | High-temperature Grease |

(b) Install the 3 planetary gears to the repair service starter kit.

2. INSTALL RUBBER SEAL

(a) Install the rubber seal to the repair service starter kit.

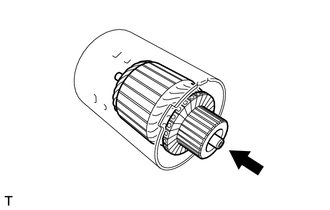

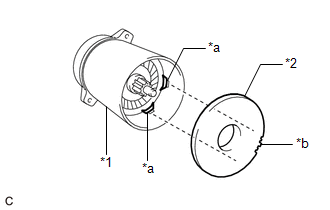

3. INSTALL STARTER ARMATURE ASSEMBLY

| (a) Install the starter armature assembly to the starter yoke assembly. NOTICE: The magnet of the starter yoke assembly may attract the starter armature assembly when the starter armature assembly is installed, causing the magnet to break. |

|

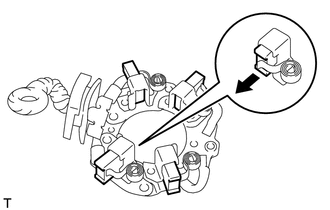

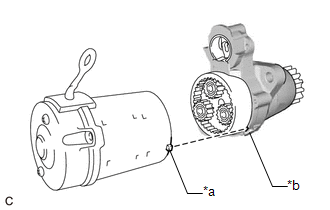

4. INSTALL STARTER BRUSH HOLDER ASSEMBLY

| (a) Hold the brush spring back and set the 4 brushes as shown in the illustration. |

|

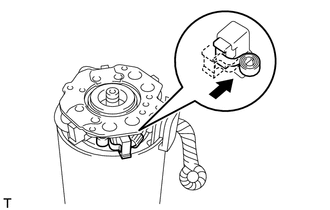

| (b) Install the starter brush holder assembly to the starter armature assembly and push in the 4 brushes as shown in the illustration. |

|

| (c) Fit the protrusion of the grommet between the negative (-) brush holder plate and positive (+) motor lead wire. |

|

5. INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY

| (a) Install the starter commutator end frame assembly to the starter yoke assembly. NOTICE: Align the field coil lead wire rubber of the starter yoke assembly with the cutout of the starter commutator end frame assembly. |

|

(b) Install the 2 screws.

Torque:

1.5 N·m {15 kgf·cm, 13 in·lbf}

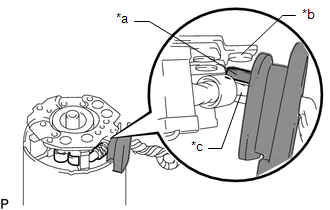

6. INSTALL STARTER ARMATURE PLATE

| (a) Align the starter armature plate so that the protrusion fits between the stoppers of the starter yoke assembly, and install the starter armature plate. NOTICE: Make sure the protrusion of the starter armature plate is inserted between the stoppers of the starter yoke assembly. |

|

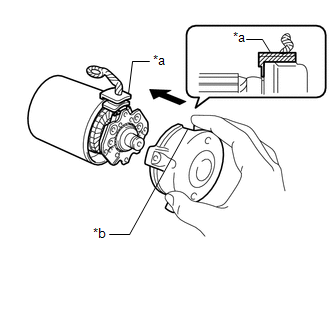

7. INSTALL STARTER YOKE ASSEMBLY

| (a) Align the protrusion of the starter yoke assembly with the cutout of the repair service starter kit. |

|

(b) Using a T25 "TORX" socket wrench, install the starter yoke assembly with the 2 through bolts.

Torque:

6.0 N·m {61 kgf·cm, 53 in·lbf}

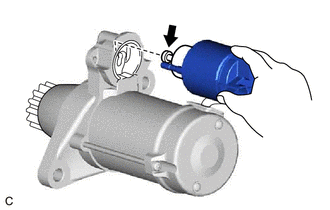

8. INSTALL MAGNET STARTER SWITCH ASSEMBLY

(a) Apply high-temperature grease to the plunger as shown in the illustration.

.png) | High-temperature Grease |

(b) Hang the hook of the magnet starter switch assembly on the pinion drive lever.

(c) Install the magnet starter switch assembly with the 2 nuts.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

(d) Connect the field coil lead wire to the magnet starter switch assembly with the nut.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}