Lexus ES: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK AUXILIARY BATTERY

(a) Check that the auxiliary battery cables are connected to the correct terminals.

If they are not, connect them properly.

(b) Check the auxiliary battery for damage and deformation. If severe damage, deformation or leakage is found, replace the auxiliary battery.

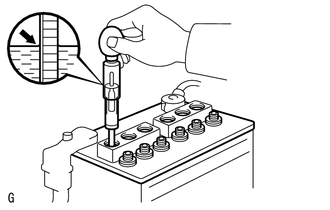

(c) Check the electrolyte level in each cell.

(1) For maintenance-free batteries:

- If the electrolyte level is below the lower line, replace the battery.

-

If the electrolyte level is above the lower line, check the auxiliary battery voltage when cranking the engine. If the voltage is less than 11 V, recharge or replace the auxiliary battery.

HINT:

Before checking the auxiliary battery voltage, turn off all the electrical systems (headlights, blower motor, rear window defogger, etc.).

| (2) For non-maintenance-free batteries:

|

|

2. CHECK AUXILIARY BATTERY VOLTAGE

(a) Turn the power switch off and turn on the high beam headlights for 30 seconds. This will remove the surface charge from the auxiliary battery.

(b) Measure the auxiliary battery voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition | Result |

|---|---|---|---|

| Positive (+) auxiliary battery terminal - Negative (-) auxiliary battery terminal | 20°C (68°F), Power switch off | 12.0 V or higher | Auxiliary battery is OK |

| 12.0 V or less | Recharge auxiliary battery |

3. RECHARGE AUXILIARY BATTERY

(a) Recharge the auxiliary battery.

HINT:

- Recharge the auxiliary battery according to the charger's instructions.

- Apply the appropriate charging current according to the type of auxiliary battery shown in the table below.

| Charge Method | Charging Current |

|---|---|

| Normal | Below 5 A |

| Quick | Below 15 A |

(b) Turn the power switch off and turn on the high beam headlights for 30 seconds. This will remove the surface charge from the auxiliary battery.

(c) Measure the auxiliary battery voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition | Result |

|---|---|---|---|

| Positive (+) auxiliary battery terminal - Negative (-) auxiliary battery terminal | 20°C (68°F), Power switch off | 12.0 V or higher | Auxiliary battery is OK |

| 12.0 V or less | Recharge auxiliary battery |

4. CHECK AUXILIARY BATTERY TERMINAL, FUSIBLE LINK AND FUSE

(a) Check that the auxiliary battery terminals are not loose or corroded.

Torque:

Positive (+) Auxiliary Battery Terminal :

5.4 N·m {55 kgf·cm, 48 in·lbf}

Negative (-) Auxiliary Battery Terminal :

5.4 N·m {55 kgf·cm, 48 in·lbf}

If a terminal is loose or corroded, tighten or clean the terminal.

(b) Measure the resistance of each fusible link and fuse for the auxiliary battery charging system.

Standard Resistance:

Below 1 Ω

If the result is not as specified, replace the fusible link or fuse as necessary.

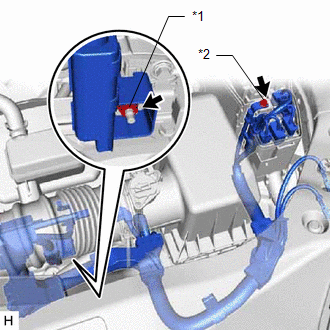

5. CHECK AMD TERMINAL

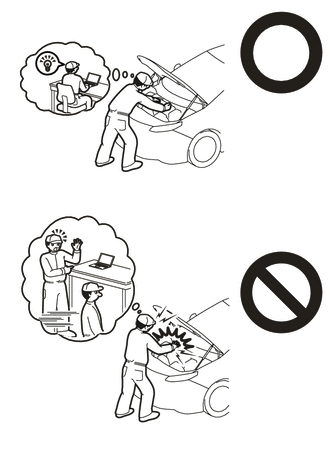

CAUTION:

-

Orange wire harnesses and connectors indicate high-voltage circuits. To prevent electric shock, always follow the procedure described in the repair manual.

Click here

.gif)

-

To prevent electric shock, wear insulated gloves when working on wire harnesses and components of the high voltage system.

(a) Remove the service plug grip.

Click here .gif)

.gif)

.gif)

(b) Check that the AMD terminal is connected securely, and there is no contact problem.

If there are any arc marks, replace the affected parts.

| (c) Check that the nut for the AMD terminal is tightened to the specified torque. Torque: Inverter with Converter Assembly Side : 10 N·m {102 kgf·cm, 7 ft·lbf} No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly Side : 8.0 N·m {82 kgf·cm, 71 in·lbf} If there are no arc marks and the AMD terminal connection is faulty, connect the AMD terminal securely. |

|

(d) Install the service plug grip.

Click here .gif)

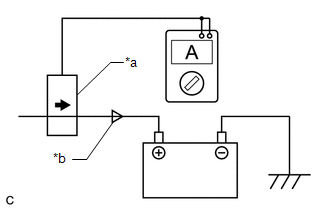

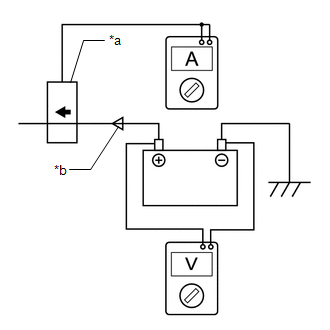

6. CHECK DC/DC CONVERTER FUNCTION

| (a) Connect the AC/DC 400 A probe to the positive (+) auxiliary battery cable. |

|

(b) Turn the power switch on (READY) and leave the vehicle as is until the electric current flowing to the auxiliary battery becomes 10 A or less.

(c) Turn on the high beam headlights, and turn the blower motor switch to the HI position and the rear window defogger on.

| (d) Measure the current and voltage according to the value(s) in the table below. Result:

If the result is not as specified, replace the inverter with converter assembly. |

|